- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

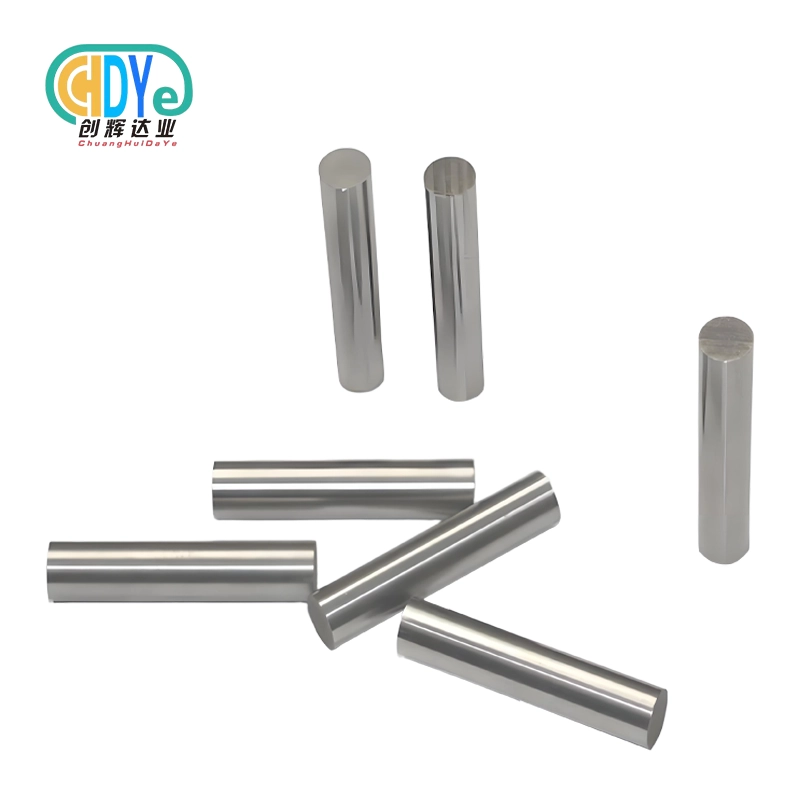

99.95% Tungsten Rod

Product Introduction

The 99.95% Tungsten Rod offered by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a high-purity tungsten product designed for demanding industrial and scientific applications. With exceptional density, thermal conductivity, and mechanical strength, this rod is suitable for high-temperature environments and high-wear conditions. Manufactured using advanced powder metallurgy and precision forging techniques, each 99.95% Tungsten Bar provides uniform microstructure, outstanding dimensional accuracy, and long service life. Available in various sizes and custom dimensions, our 99.95% Tungsten Bar ensures reliable performance for clients worldwide seeking premium-grade refractory metal materials.

99.95% tungsten bar is a high-density, high-purity metal rod mainly composed of tungsten metal, with a tungsten content usually higher than 99.95%. Therefore pure tungsten rods have excellent physical and chemical properties, such as high density, high melting point, high hardness, good conductivity and thermal conductivity, as well as excellent corrosion resistance.

1. Purity: 99.95%

2. Material: pure tungsten or tungsten alloy

3. Shape: Cylindrical or Square

4. Size: as your request, customized

5. Surface treatment: black, polished

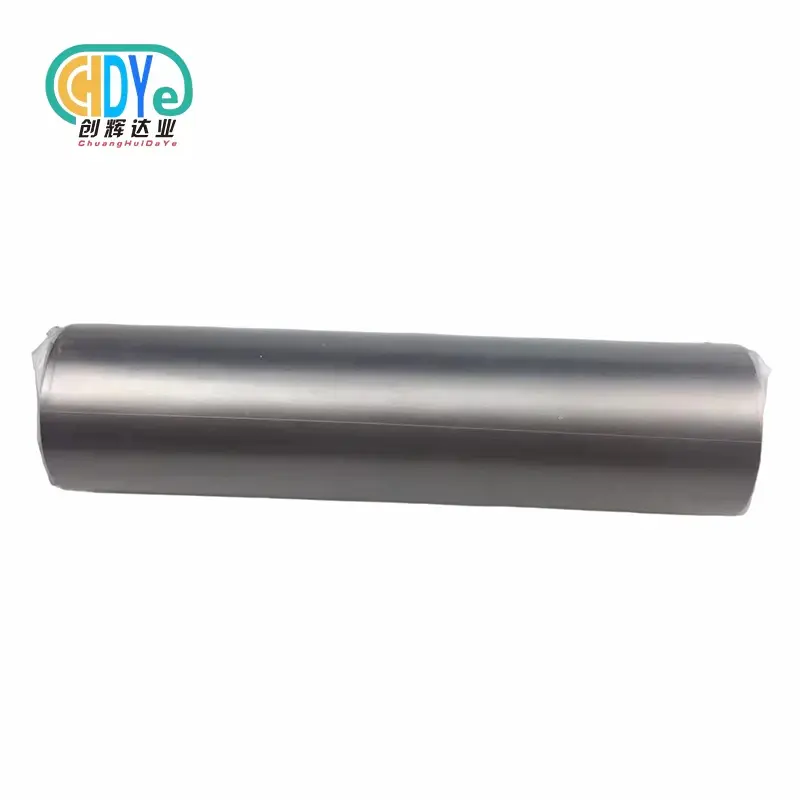

99.95% tungsten bar packing

Tungsten Rods/Bars are tagged and labeled externally to ensure efficient identification and quality control. We use soft foam paper inside, outer packaging with wooden box avoid any damage which might be caused during storage or transportation.

Ordering Process

1. Contact us directly and send your specific requirements like diameter, length, purity and quantity. We will back to you within 2 hours with a quotation.

2. If you have a drawing just email us we can check and calculate a best price for you.

3. When we reach an agreement, you need to arrange prepayment to us.

4. Begin to arrange production when we get your payment, and when finish production will inform you the actual weight, then you arrange balance payment.

5. We arrange inspection, packing and delivery.

Welcome to contact us if you have requirements of 99.95% tungsten bar, and if you need cut service just tell us and Chdymetal can cut to precise dimensions with very tight tolerances. Rather than ordering big tungsten bar and cutting the material yourself, let us do the cutting for you and reduce your risk and scrap.

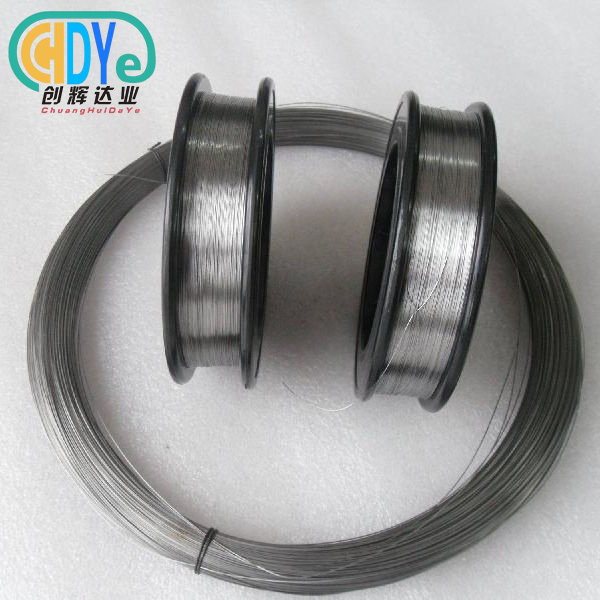

Related products

Application Advantages

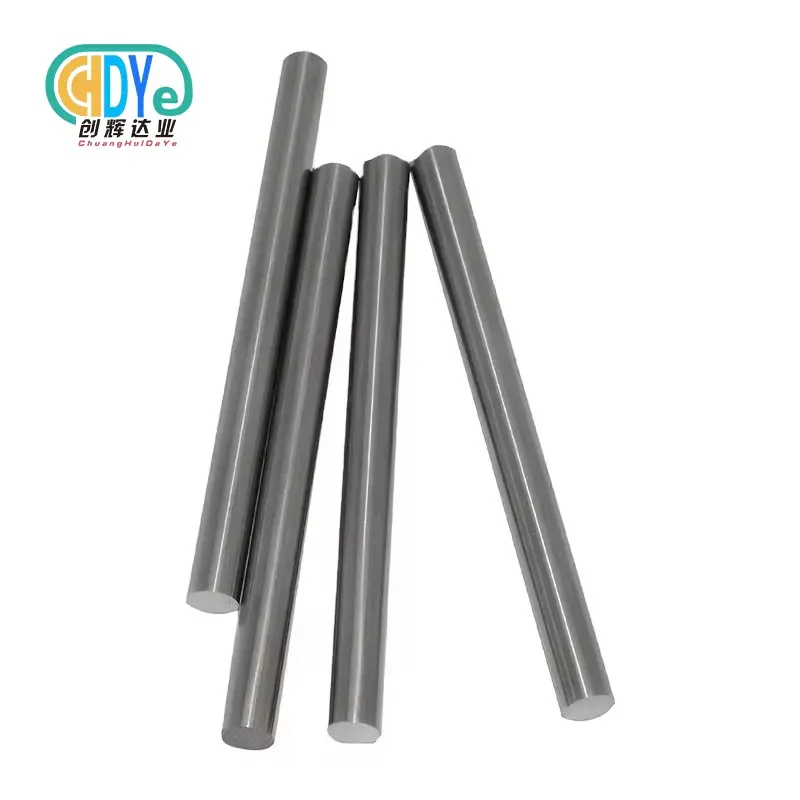

The 99.95% Tungsten Rod is extensively used across industries requiring high-performance tungsten materials:

- Aerospace & Defense: Counterweights, penetrators, radiation shielding, and precision components.

- Electronics & Semiconductors: High-temperature electrodes, filaments, and vacuum evaporation sources.

- Medical Equipment: Radiation therapy components, CT scanner counterweights, and collimators.

- Metallurgical Industry: High-temperature furnace parts, molds, and dies.

- Precision Manufacturing: Components exposed to extreme wear or thermal stress.

Its combination of purity, strength, and stability makes it ideal for high-demand applications.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Shaanxi Chuanghui Daye ensures every 99.95% Tungsten Rod meets strict quality and performance standards through a controlled production process:

- Raw Material Selection: High-purity tungsten powder verified for chemical consistency.

- Powder Pressing: Isostatic pressing forms the rod blank to ensure uniform density.

- Sintering: Vacuum or hydrogen sintering eliminates porosity and strengthens the rod.

- Forging & Rolling: Hot forging and rotary swaging refine grain structure and improve mechanical properties.

- Machining: Precision cutting and grinding achieve tight tolerances and smooth surfaces.

- Final Inspection: Each rod undergoes rigorous checks for dimensional accuracy and structural integrity.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Every 99.95% Tungsten Rod undergoes comprehensive quality control measures:

- Chemical Analysis: Confirms tungsten content of ≥99.95%.

- Ultrasonic Testing: Detects internal flaws or density variations.

- Mechanical Testing: Evaluates tensile strength, hardness, and elongation.

- Dimensional Verification: Ensures precise tolerances and geometrical accuracy.

- Surface Inspection: Guarantees a defect-free, smooth finish.

All products are certified under ISO 9001:2015, providing reliable documentation and batch traceability.

R&D and Customization

Our experienced R&D team continuously enhances the properties and manufacturing techniques of the 99.95% Tungsten Rod:

- Development of fine-grain, high-density rods.

- Improved oxidation and high-temperature performance.

- Customized dimensions, grades, and alloying options.

- Precision machining for specialized industrial or scientific applications.

Clients can request tailored specifications to match project-specific requirements.

Packaging & Global Logistics

Each 99.95% Tungsten Rod is carefully packaged to prevent damage during transportation:

- Packaging: Anti-rust film, vacuum sealing, foam protection, and export-standard wooden boxes.

- Marking: Clear labeling of grade, size, and batch number.

- Logistics: Reliable air, sea, and land transport to over 50 countries.

This ensures safe delivery to international clients while maintaining product integrity.

|

|

|

|

|

|

|

|

|

|

|

|

OEM & Customization Service

Shaanxi Chuanghui Daye provides comprehensive OEM and ODM support for 99.95% Tungsten Rod:

- Production according to custom drawings and tolerance specifications.

- Small-batch prototyping and specialized manufacturing.

- Technical guidance in material selection and application.

- Confidential collaboration with distributors, manufacturers, and end-users.

These services allow flexible and precise solutions for diverse industrial requirements.

Inspection Process

The inspection process for 99.95% Tungsten Rod ensures consistent quality and performance:

- Raw Material Verification: Chemical composition and purity checks.

- In-Process Monitoring: Real-time supervision of pressing, sintering, and forging.

- Non-Destructive Testing: Ultrasonic and density inspections.

- Dimensional Accuracy Check: Coordinate measuring tools confirm tolerances.

- Final Verification: Packaging, labeling, and documentation before shipment.

Why Choose Us

- 30+ Years Expertise: Advanced knowledge in refractory metal production.

- High-Tech Facilities: Electron beam furnaces, forging lines, and precision machining.

- Strict Quality Assurance: ISO 9001:2015 certified, full batch traceability.

- Global Export Capability: Delivering to over 50 countries efficiently.

- Customizable Options: Support for non-standard dimensions and specifications.

- Fast Delivery: Standard orders ready within 7 days.

- Professional Service: Technical consultation and after-sales support worldwide.

|

|

|

|

|

|

FAQs

Q1: What purity level does your tungsten rod achieve?

A1: Our rods have a tungsten content of 99.95%, ensuring high strength and thermal stability.

Q2: Can you produce custom sizes and machining?

A2: Yes, the 99.95% Tungsten Rod can be customized according to customer specifications and drawings.

Q3: Which industries are the main users of this rod?

A3: Aerospace, electronics, metallurgical, and medical industries are the primary users.

Q4: What surface finishes are available?

A4: Ground, polished, and machined finishes are available based on requirements.

Q5: How are products packaged for export?

A5: Each rod is vacuum-packed, cushioned with foam, and placed in export-standard wooden cases for safe transport.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email