- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

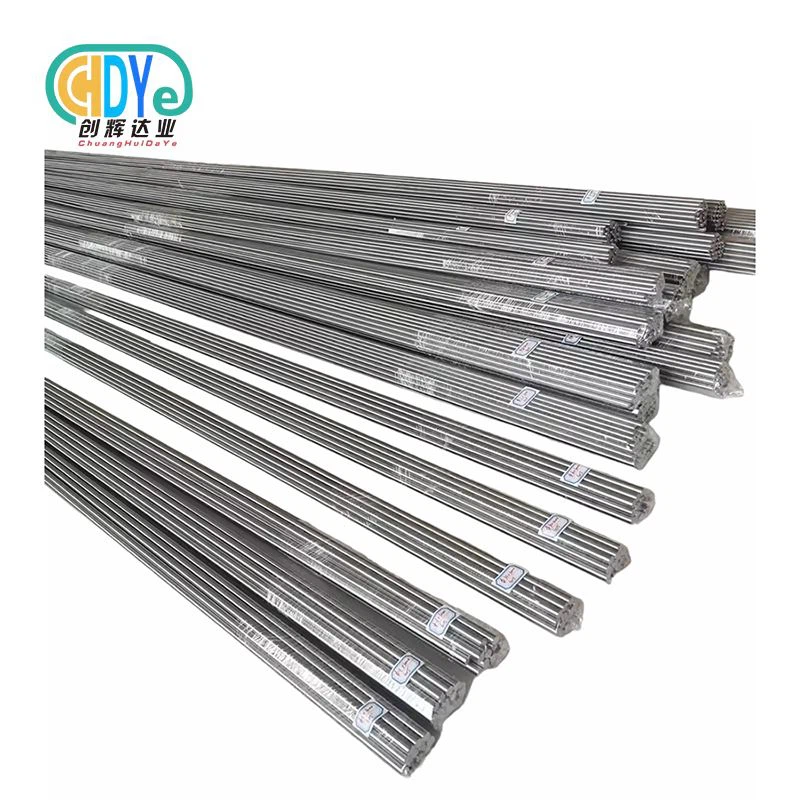

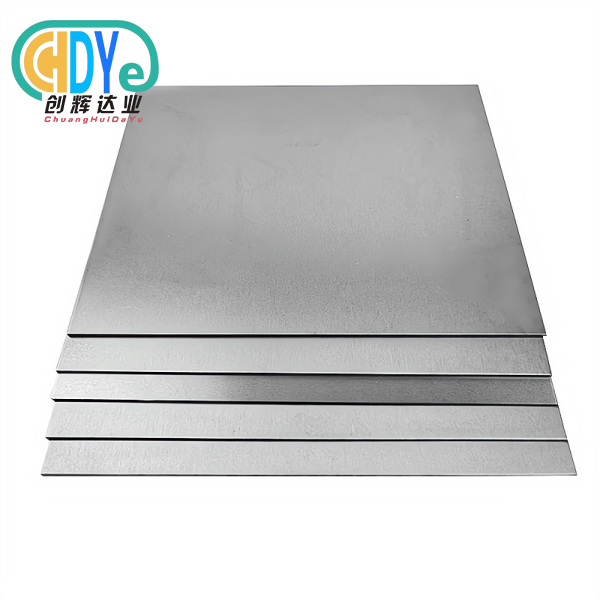

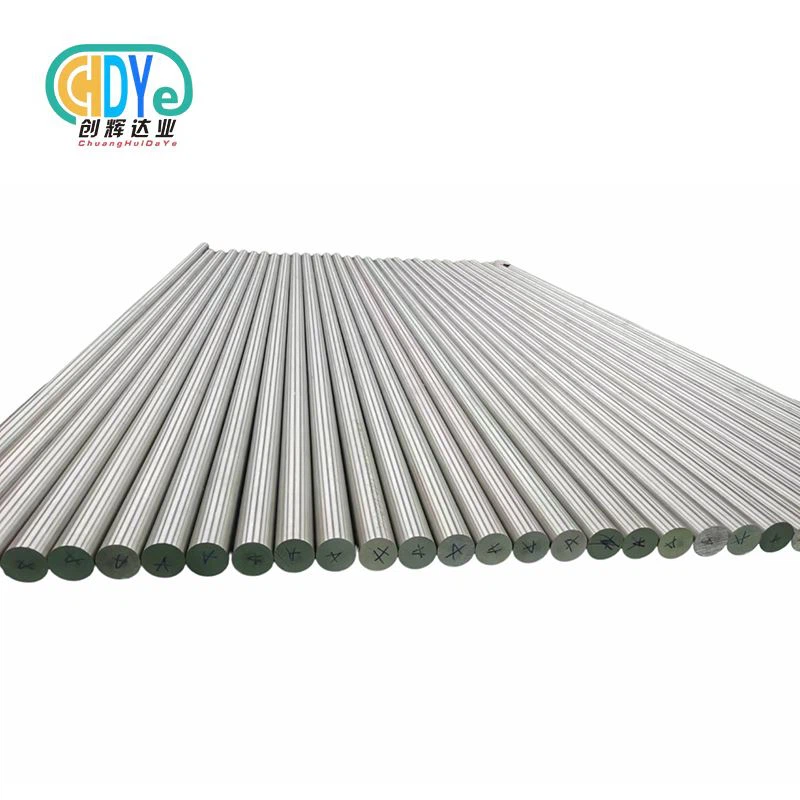

niobium target plate

2.Standard: ASTM B393

3.Surface: Polished, annealed, Cold-rolled bright

Product Introduction

Looking for premium quality niobium target plate for your sputtering applications? You've come to the right place. Our niobium target plate delivers exceptional purity levels exceeding 99.9%, making it perfect for electronics manufacturing, thin film deposition, and advanced coating processes. With over 30 years of experience in rare metal processing, Shaanxi Chuanghui Daye Metal Material Co., Ltd. provides you with reliable, high-performance materials that meet your most demanding specifications.

Our niobium targets offer superior thermal conductivity and chemical inertness. These properties make them ideal for consistent, long-term performance in your production environments.

Key Features and Benefits

- Ultra-high purity: 99.9% minimum niobium content ensures consistent results

- Excellent thermal properties: Superior heat dissipation prevents target degradation

- Chemical stability: Resistant to corrosion and contamination

- Uniform grain structure: Provides even sputtering rates across the entire surface

- Low activation: Minimal radioactive byproducts for safer handling

- Custom dimensions: Tailored to fit your specific equipment requirements

- Long service life: Reduces downtime and replacement costs

Technical Specifications

|

Purity |

99.9% |

|

Technics |

Cold rolled |

|

Standard |

ASTM B393 / ASME SB393 |

|

Density |

8.57g/cm3 |

|

Application |

Widely used in chemical, electronics, aviation and aerospace fields |

|

Specification |

Customized |

|

Hardness |

Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

|

Certification |

ISO 9001:2015 |

|

Payment terms |

30% TT in advance, 70% balance before shipment |

Chemical composition

|

Material |

Main elements(%) |

Impurities (Maximum %) |

||||||||||

|

Nb |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Ta |

O |

C |

H |

N |

|

|

RO4200 |

Remainder |

0.004 |

0.004 |

0.002 |

0.005 |

0.005 |

0.002 |

0.07 |

0.015 |

0.0040 |

0.0015 |

0.003 |

|

RO4210 |

Remainder |

0.01 |

0.01 |

0.005 |

0.02 |

0.01 |

0.004 |

0.10 |

0.02 |

0.01 |

0.0015 |

0.01

|

Mechanical Properties

|

Grade |

Tensile strength psi(MPa), ≥ |

Yield strength δ0.2, psi (MPa),≥ |

Elongation in 1"/2" gage length, %, ≥ |

|

|

>=0.010 |

<0.010 |

|||

|

RO4200 RO4210 |

18000 (125) |

12000 (85) |

25 |

20 |

Available Grades and Materials

We offer various niobium grades to meet your specific requirements:

- Industrial Grade: Cost-effective solution for standard sputtering processes

- Research Grade: Ultra-pure material for laboratory applications

- Custom Alloys: Niobium-titanium and other specialized compositions available upon request

Manufacturing Process

Our niobium target plates undergo rigorous manufacturing steps to ensure superior quality:

- Raw Material Selection: We source high-purity niobium ingots

- Melting and Refining: Vacuum arc melting removes impurities

- Forging and Rolling: Controlled deformation creates uniform grain structure

- Heat Treatment: Stress relief and grain optimization

- Machining: Precision cutting to your exact specifications

- Surface Finishing: Smooth surface preparation for optimal sputtering

- Quality Testing: Comprehensive inspection before shipment

|

|

|

|

|

|

|

|

Applications and Industries

Our niobium target plate serves diverse industrial applications:

- Semiconductor Manufacturing: Thin film deposition for electronic devices

- Solar Cell Production: Anti-reflective and conductive coatings

- Optical Coatings: High-performance mirrors and filters

- Medical Cyclotrons: Target materials for radioisotope production

- Research Laboratories: Material science and physics research

- Aerospace Components: Specialized coating applications

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain strict dimensional tolerances to ensure perfect fit in your equipment:

- Thickness tolerance: ±0.05 mm for materials under 5 mm

- Width tolerance: ±0.5 mm

- Length tolerance: ±1.0 mm

- Flatness: Better than 0.1 mm across the entire surface

- Surface roughness: Ra ≤ 0.8 μm

Product Features in Detail

Superior Sputtering Performance: Our targets provide consistent deposition rates and excellent film uniformity. The fine grain structure ensures smooth, even material ejection during the sputtering process.

Enhanced Durability: The high-density construction and optimal grain orientation extend target life significantly. This reduces your operational costs and minimizes production interruptions.

Low Outgassing: Vacuum-processed materials exhibit minimal gas release during operation. This maintains chamber cleanliness and improves film quality.

Quality Assurance and Testing

Every niobium target plate undergoes comprehensive quality control:

- Chemical Analysis: ICP-MS testing verifies purity levels

- Microstructure Examination: Metallographic analysis ensures uniform grain structure

- Dimensional Inspection: Coordinate measuring machine verification

- Surface Quality Check: Visual and instrumental surface assessment

- Density Measurement: Archimedes method confirmation

- Ultrasonic Testing: Internal defect detection

|

|

|

OEM & Customization Services

We understand that every application has unique requirements. Our engineering team works closely with you to develop customized solutions:

- Custom Shapes: Rectangular, circular, or complex geometries

- Backing Plates: Copper or other materials for enhanced cooling

- Special Alloys: Custom compositions for specific applications

- Surface Treatments: Specialized finishes as needed

- Bonding Services: Professional target-to-backing plate assembly

Packaging and Shipping

Your targets receive careful protection during transit:

- Individual Wrapping: Each piece wrapped in protective film

- Foam Cushioning: Shock-absorbing materials prevent damage

- Wooden Crates: Sturdy packaging for international shipping

- Documentation: Complete certificates and test reports included

- Express Shipping: Fast delivery options available worldwide

|

|

|

|

|

|

|

|

|

Why Choose Us

Three Decades of Expertise: Our founder brings over 30 years of rare metal industry experience. This knowledge ensures you receive products that exceed expectations.

Global Reach: We successfully serve customers in the United States, Germany, South Korea, Singapore, and over 50 countries worldwide.

Quality First Philosophy: Every product undergoes rigorous testing before shipment. We stand behind our quality with comprehensive support.

Competitive Pricing: Direct manufacturer pricing without middleman markups. You get exceptional value without compromising quality.

Reliable Delivery: On-time shipment track record ensures your production schedules stay on track.

|

|

|

|

|

|

FAQs

Q: What's the minimum order quantity?

A: We accommodate orders from single pieces to large production quantities.

Q: Can you provide material certificates?

A: Yes, we include complete chemical analysis and property certificates with every shipment.

Q: Do you offer technical support?

A: Our experienced engineers provide comprehensive technical assistance throughout your project.

Q: What's your typical lead time?

A: Standard products ship within 1-2 weeks. Custom orders may require 2-3 weeks.

Contact Us

Ready to enhance your sputtering processes with premium niobium target plate? Our technical team stands ready to assist with your specific requirements.

Email: info@chdymetal.com

Mob./what's app.: 86-18049386902

Contact us today for detailed quotes, technical specifications, or custom solutions. We look forward to becoming your trusted partner for high-quality rare metal products.

Learn about our latest products and discounts through SMS or email