- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

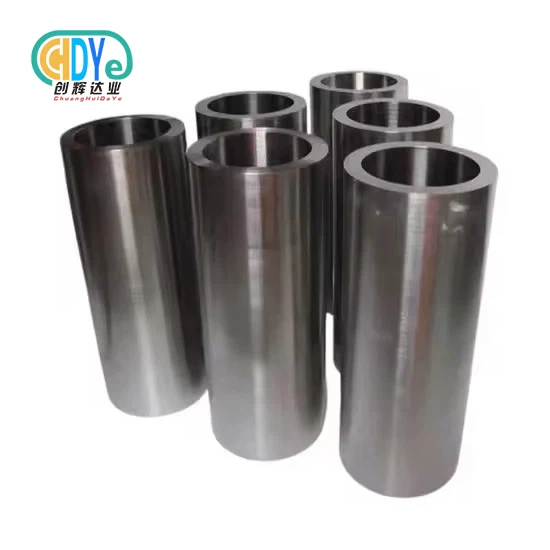

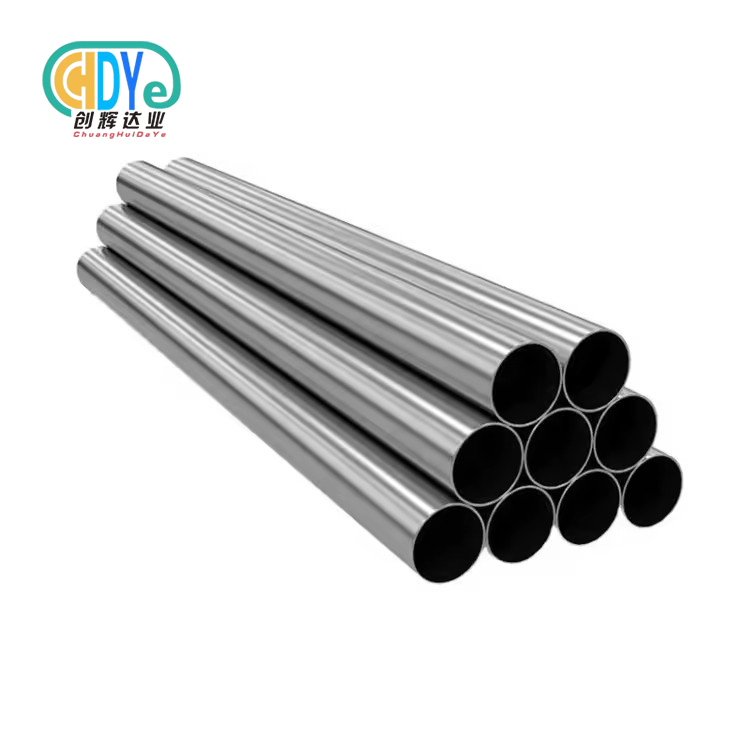

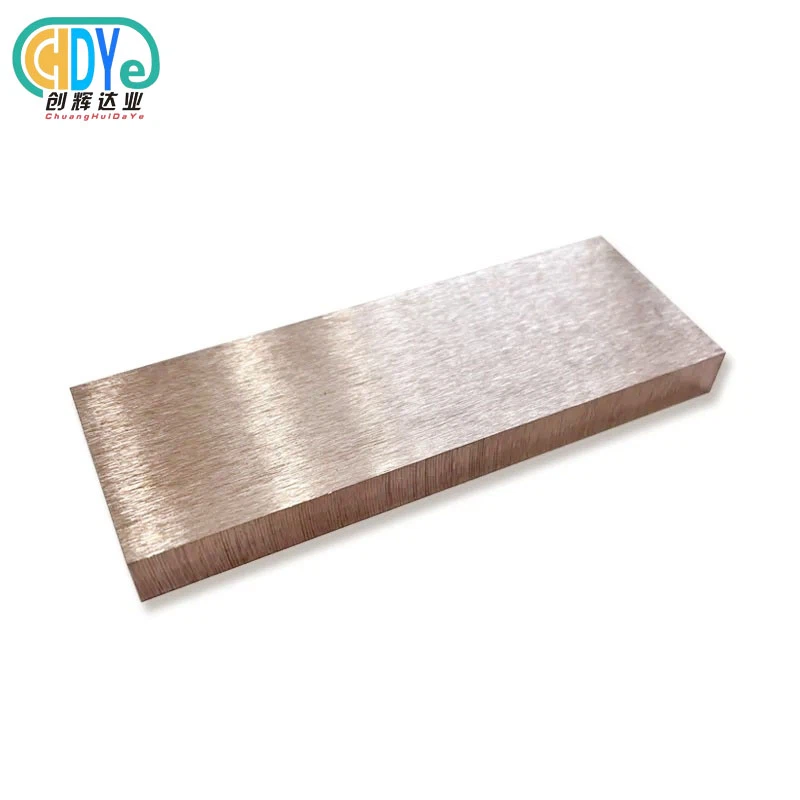

Pure Niobium Rod

2.Standard: ASTM B 392

3.Dimensions: Diameter: 3-120mm* Length:<2m

Product Introduction

The Pure Niobium Rod from Shaanxi Chuanghui Daye Metal Material Co., Ltd. is produced using high-purity niobium, offering exceptional corrosion resistance, excellent ductility, and reliable mechanical strength. Each Pure Niobium Bar undergoes precise forging and machining to ensure uniform diameter, smooth surface finish, and consistent quality. This makes the Pure Niobium Bar ideal for high-performance applications in demanding industrial environments.

Pure Niobium Baris made of pure niobium with purity over 99.95%, Pure Niobium Bars have good cold working properties and are widely used in the fields of chemistry, electronics, aviation and aerospace.

Pure Niobium Bar Specification:

Material: Pure Niobium

Purity: 99.95%

Standard: ASTM B 392

Dimensions: Diameter: 3-120mm* Length:<2m

Pure Niobium Rod Applications:

Used in making vacuum furnaces' attachments and supports of high temperature

Used for the manufacturing of reaction vessels.

Used in equipments which are resistant to nitric acid, sulfuric acid, hydrochloric acid

Used in manufacturing super alloys and electron-beam melting. (high-temperature alloys like Ta-Nb alloys, corrosion-resistant alloy additives.)

Used in chemical industry and oil industry (corrosion resistance equipment)

Application Advantages

The Pure Niobium Rod is widely used across multiple industries:

- Aerospace & Defense: Components for high-temperature applications, superconducting magnets, and structural parts.

- Electronics & Semiconductors: Electrodes, conductive elements, and connectors.

- Medical Equipment: Biocompatible surgical tools, implants, and medical devices.

- Chemical Processing: Corrosion-resistant piping, reactors, and storage tanks.

- Energy & Environmental Engineering: Heat exchangers, renewable energy systems, and specialized machinery.

heat exchangers. Manufacturing & Process Flow

Production of Pure Niobium Rod includes the following steps:

- Raw Material Selection: Only premium-grade niobium ingots are used.

- Vacuum Melting: Eliminates impurities and ensures material uniformity.

- Hot Forging & Rolling: Shapes the ingots into bars and rods.

- Precision Machining: Achieves exact diameters and smooth surface finishes.

- Annealing: Enhances ductility and mechanical properties.

- Surface Inspection & Finishing: Guarantees defect-free, high-quality Pure Niobium Rod.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Every Pure Niobium Rod undergoes strict quality inspections:

- Chemical Analysis: Ensures high purity and conformity to standards.

- Mechanical Testing: Evaluates tensile strength, hardness, and elongation.

- Dimensional Verification: Checks diameter, roundness, and length.

- Surface Inspection: Detects scratches, pits, or surface defects.

- Non-Destructive Testing (NDT): Confirms internal integrity.

R&D and Customization

Our experienced R&D team provides customization options for Pure Niobium Rod:

- Tailored diameters, lengths, and mechanical properties

- Alloy composition adjustments for specialized applications

- Prototype and small-batch production

- Technical guidance for material selection and process optimization

Packaging & Global Logistics

To ensure safe delivery, the Pure Niobium Rod is:

- Wrapped in vacuum or anti-rust film

- Secured with foam or braces to prevent deformation

- Packaged in export-standard wooden crates with clear labeling

- Delivered via reliable air, sea, or land transport to global clients

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

Why Choose Us

- 30+ years of rare metal expertise

- ISO 9001:2015 certified

- Advanced production equipment

- Fast 7-day delivery for standard sizes

- Global export network and OEM support

|

|

|

|

|

|

FAQs

Q1: What standards does the rod meet?

A1: ASTM, ISO, and other international standards.

Q2: Can you produce custom sizes?

A2: Yes, we provide full customization.

Q3: How is quality ensured?

A3: Through chemical analysis, mechanical testing, dimensional verification, and non-destructive testing.

Q4: What is the lead time?

A4: Standard products ship within 7 days; customized orders vary.

Q5: Do you provide international shipping?

A5: Yes, we ship worldwide via reliable logistics.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email