- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

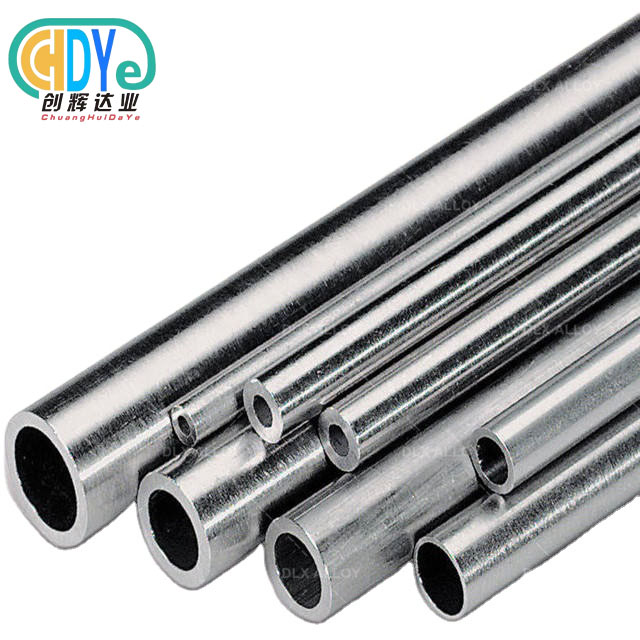

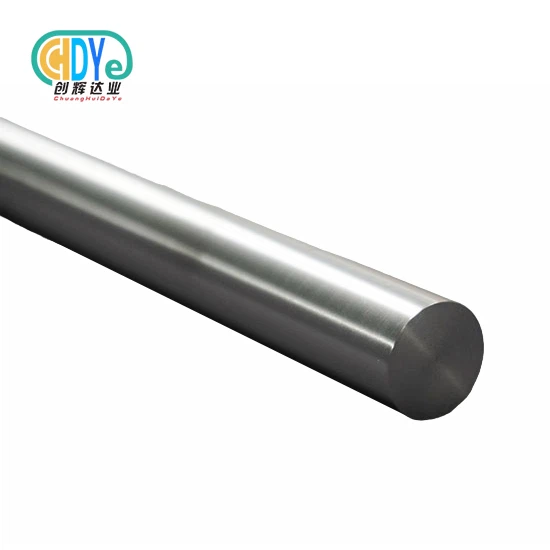

Niobium Titanium Alloy Wire

2.Diameter: 0.1-4mm

3.Length: as customer’s request 4.Condition: Annealed

Product Introduction

The Niobium Titanium Alloy Wire from Shaanxi Chuanghui Daye Metal Material Co., Ltd. is crafted from high-quality niobium-titanium alloys, offering excellent mechanical strength, corrosion resistance, and flexibility. Designed for high-performance applications, this wire delivers consistent conductivity and durability. Each Niobium Titanium Alloy Wire is produced in accordance with ASTM, AMS, ISO, and GB standards, ensuring superior quality and reliable performance. Our precise manufacturing processes guarantee smooth surface finish, uniform diameter, and outstanding tensile properties.

Chdymetal offers niobium titanium alloy wire is made of NbTi alloy ingot. Niobium titanium alloys are ideal for applications like superconducting magnets, jet engines, heat exchangers, and chemical processing equipment where both high strength and temperature stability are critical.

Specification

1. Grade: Nb52-Ti48, Nb50%-Ti50%, and Nb45%-Ti55%.

2. Product Shape: Spooled

3. Diameter: 0.1-4mm

4. Length: as customer's request

5. Condition: Annealed

Application

Niobium titanium alloy is an important alloyed superconductor material. Its superconductive transition temperature is 8K to 10K. If other elements are added into the alloy, superconductivity will be improved.

· Niobium titanium alloy is sintered from alloyed powder. We use vacuum electrode arc furnace or electron-beam furnace to melt the alloyed ingots. The niobium titanium alloys can be in various forms such as sheet, bar, wire, or target.

1. it is used in superconducting industry. It is strong enough to be used in aerospace industry.

2. Nb-55Ti can be used in anti-corrosion engineering.

3. Nb-55Ti is used for high pressure equipment to filter Gold and Nickel in high pressure and high concentration oxygen environment. Niobium also acts as flame retardant in this environment.

4. Niobium-containing Titanium alloys, such as IMI367, are used in surgical implants, particularly in the production of femoral components for hip repair surgery.

5. Niobium titanium wire can be processed into superconducting cables its excellent superconducting properties.

Application Advantages

The Niobium Titanium Alloy Wire is widely used across multiple industries:

- Aerospace & Defense: Components in high-temperature environments, superconducting systems, and structural applications.

- Electronics & Semiconductors: Sputtering targets, electrical wiring, and specialized electronic components.

- Medical Equipment: Biocompatible devices, implants, and surgical instruments.

- Chemical Processing: Resistant to aggressive media in reactors, pipelines, and high-corrosion environments.

- Energy & Environmental Engineering: Used in reactors, heat exchangers, and renewable energy systems requiring high-strength, corrosion-resistant wire.

resistant wire. Manufacturing & Process Flow

The production of Niobium Titanium Alloy Wire includes a series of controlled stages:

- Raw Material Inspection: High-purity niobium and titanium alloy ingots are analyzed for chemical composition.

- Vacuum Melting: Ensures a contaminant-free, homogeneous alloy.

- Hot Extrusion & Forging: Converts ingots into initial wire forms.

- Cold Drawing & Annealing: Improves mechanical properties, surface smoothness, and dimensional accuracy.

- Precision Sizing: Ensures the wire meets strict diameter tolerances.

- Final Inspection & Cleaning: Prepares wire for packaging and shipment.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Every Niobium Titanium Alloy Wire undergoes rigorous testing:

- Chemical Composition Analysis to verify alloy integrity

- Mechanical Testing including tensile strength, elongation, and hardness

- Dimensional Checks to ensure uniformity in diameter and length

- Surface Finish Examination to detect defects or irregularities

- Non-Destructive Testing for internal flaw detection

These steps guarantee consistent high performance and compliance with international standards.

R&D and Customization

Our R&D team provides tailored solutions for Niobium Titanium Alloy Wire, including:

- Custom diameters, lengths, and surface finishes

- Alloy composition optimization for specific applications

- Small-batch or prototype production for research and pilot projects

- Consultation on material selection and application performance

Innovation and technical expertise enable us to meet complex industrial requirements efficiently.

Packaging & Global Logistics

To ensure safe delivery, each Niobium Titanium Alloy Wire is packaged with care:

- Wrapped in anti-rust film or vacuum packaging to prevent oxidation

- Foam or reel protection to avoid deformation during transport

- Placed in export-standard wooden boxes with clear specification and batch labels

- Shipped via reliable air, sea, or land logistics solutions to over 50 countries worldwide

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Chuanghui Daye offers professional OEM and customization for Niobium Titanium Alloy Wire:

- Custom diameters, lengths, and alloy compositions

- Wire drawing and surface finishing per client requirements

- Prototype, small-batch, or large-scale production

- Technical support for material selection and application optimization

We ensure every wire meets your specifications with high-quality consistency.

Inspection Process

The Niobium Titanium Alloy Wire undergoes a comprehensive inspection workflow:

- Incoming Material Verification

- Process Monitoring during extrusion, drawing, and annealing

- Intermediate Diameter & Surface Checks

- Mechanical & Chemical Testing

- Final Packaging Inspection

This ensures traceable, high-quality wire for all industrial applications.

Why Choose Us

- 30+ Years of Experience in rare metal production

- ISO 9001:2015 Certified Quality Management System

- Advanced Production Facilities including electron beam furnaces and cold drawing machines

- 7-Day Fast Delivery for standard specifications

- Global Export Network to over 50 countries

- Customized OEM & Technical Services to meet precise client needs

Niobium Titanium Alloy Wire from Chuanghui Daye combines reliability, high performance, and expert support for industrial and high-tech applications.

|

|

|

|

|

|

FAQs

Q1: What standards are your Niobium Titanium Alloy Wires manufactured to?

A1: All wires comply with ASTM, AMS, ISO, and GB standards.

Q2: Can you produce custom diameters and lengths for Niobium Titanium Alloy Wire?

A2: Yes, we provide full customization according to client specifications.

Q3: How do you ensure the wire quality?

A3: Through chemical analysis, mechanical testing, surface inspection, and non-destructive testing.

Q4: What is the typical lead time for orders?

A4: Standard wires ship within 7 days; customized orders vary based on specifications.

Q5: Do you ship internationally?

A5: Yes, we provide reliable air, sea, and land shipping solutions worldwide.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email