- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

niobium titanium tube

2. OD: 1–200 mm

3. Wall thickness: 0.2–10 mm

4. Length: up to 3000 mm

5. Density: 8.6–8.7 g/cm³

6. Applications: Aerospace, medical

7. Seamless manufacture

Product Introduction

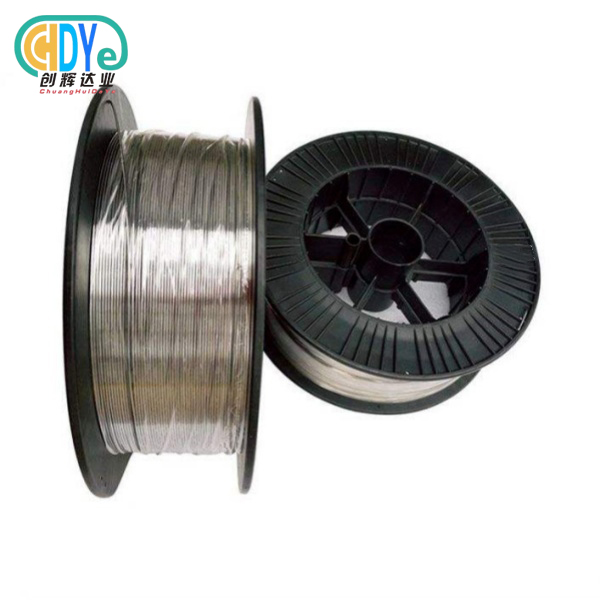

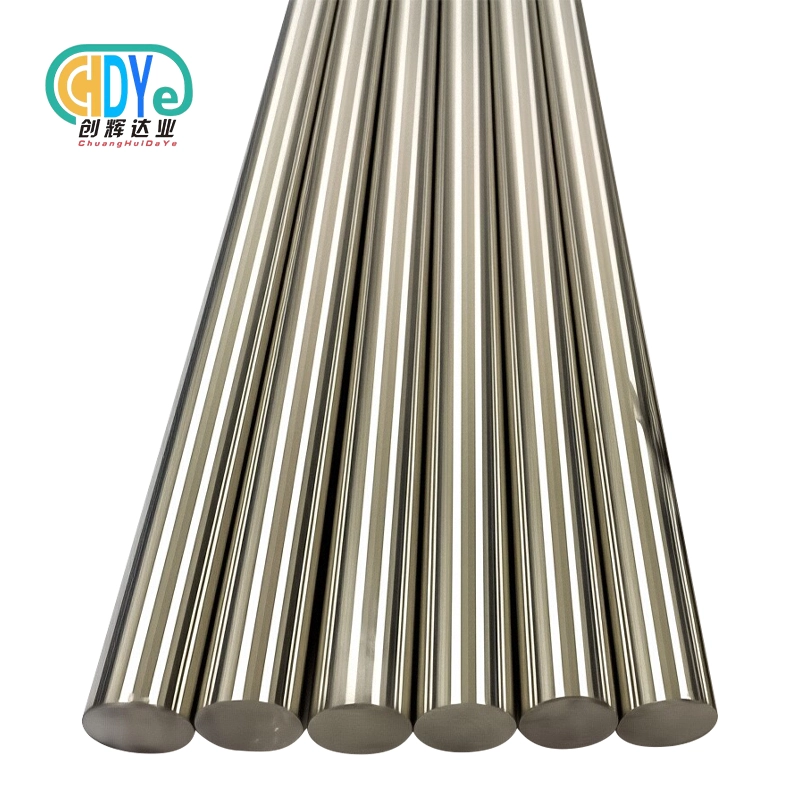

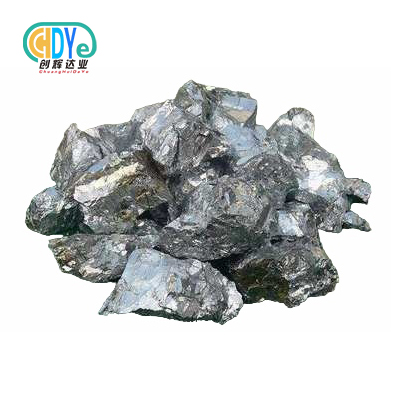

Niobium titanium alloy is an important alloyed superconductor material. Its superconductive transition temperature is 8K to 10K. If other elements are added into the alloy, superconductivity will be improved.Niobium titanium alloy is sintered from alloyed powder. We use vacuum electrode arc furnace or electron-beam furnace to melt the alloyed ingots. The niobium titanium alloys can be in various forms such as sheet, bar, wire, tube or target.

Key Features and Benefits

- Superior Superconducting Properties: Excellent critical current density for magnetic field applications

- Seamless Construction: Enhanced structural integrity and uniform wall thickness

- Corrosion Resistance: Outstanding performance in challenging environments

- Lightweight Design: Optimal strength-to-weight ratio for aerospace applications

- Customizable Dimensions: Tailored specifications to meet your exact requirements

- High Purity: Premium-grade materials ensuring consistent performance

Technical Specifications

|

Product Name |

niobium titanium tube |

|

Material |

niobium -Titanium alloy |

|

Dimension |

As per your request |

|

Grade |

Nb53-Ti47, Nb50%-Ti50%, and Nb45%-Ti55%. |

|

Characteristic |

Melting point : 2468℃ Boiling point : 4744℃ |

|

Application |

Widely used in chemical, electronics, aviation and aerospace fields |

|

Product Features |

Excellent Corrosion Resistance Good resistance to effect of heat |

|

Packing |

Foam material inside, wooden box outside |

|

Payment terms |

30% TT in advance, 70% balance before shipment |

|

Delivery time |

stock size within 1-5days, production time 15 working days |

|

Sample |

Sample order are supported |

Available Grades and Materials

Our product line features various niobium-titanium compositions optimized for different applications. Standard grades include Nb-47Ti and Nb-50Ti alloys, each offering unique superconducting characteristics. We also provide custom alloy compositions based on your specific requirements.

Manufacturing Process

We employ state-of-the-art seamless tube manufacturing processes. Our production begins with premium-grade raw materials, followed by precision forming, heat treatment, and quality inspection. Each tube undergoes rigorous testing to ensure dimensional accuracy and material properties meet international standards.

|

|

|

|

|

|

|

|

Applications and Industries

- Medical Equipment: MRI machines and medical imaging systems

- Aerospace: Satellite components and space exploration equipment

- Research Facilities: Particle accelerators and scientific instruments

- Energy Sector: Superconducting magnetic energy storage systems

- Electronics: Advanced magnetic field applications

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain strict dimensional tolerances to ensure your components fit perfectly. Standard tolerances include ±0.05mm for outer diameter and ±0.02mm for wall thickness. Custom tolerances available upon request.

Every niobium titanium tube undergoes comprehensive quality testing including dimensional inspection, material composition analysis, and mechanical property verification. Our quality management system ensures consistent product excellence and traceability throughout the manufacturing process.

OEM & Customization Services

We specialize in custom manufacturing solutions. Our engineering team works closely with you to develop tubes meeting your exact specifications. From prototype development to full-scale production, we provide comprehensive support throughout your project lifecycle.

|

|

|

Packaging and Shipping

Products are carefully packaged to prevent damage during transit. We use protective materials and secure packaging methods suitable for international shipping. Our logistics team coordinates delivery to over 50 countries worldwide.

Why Choose Us

Located in China's "Titanium Capital," we leverage three decades of rare metal expertise. Our commitment to quality, competitive pricing, and reliable delivery has earned trust from customers across the United States, Germany, South Korea, and Singapore. We focus on building long-term partnerships through exceptional service and continuous improvement.

|

|

|

|

|

|

FAQs

Q: What's the minimum order quantity?

A: We accommodate both small prototype orders and large production runs.

Q: Can you provide material certificates?

A: Yes, we provide complete material traceability documentation with each shipment.

Q: What's the typical lead time?

A: Standard products ship within 1-2 weeks; custom orders typically require 2-3 weeks.

Contact Us

Ready to discuss your niobium titanium tube requirements? Our technical team is here to help you select the optimal solution for your application. Contact us today at to request a quote or technical consultation. We look forward to partnering with you on your next project.

E-mail: info@chdymetal.com

Mob./what'sapp.: 86-18049386902

Learn about our latest products and discounts through SMS or email