- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

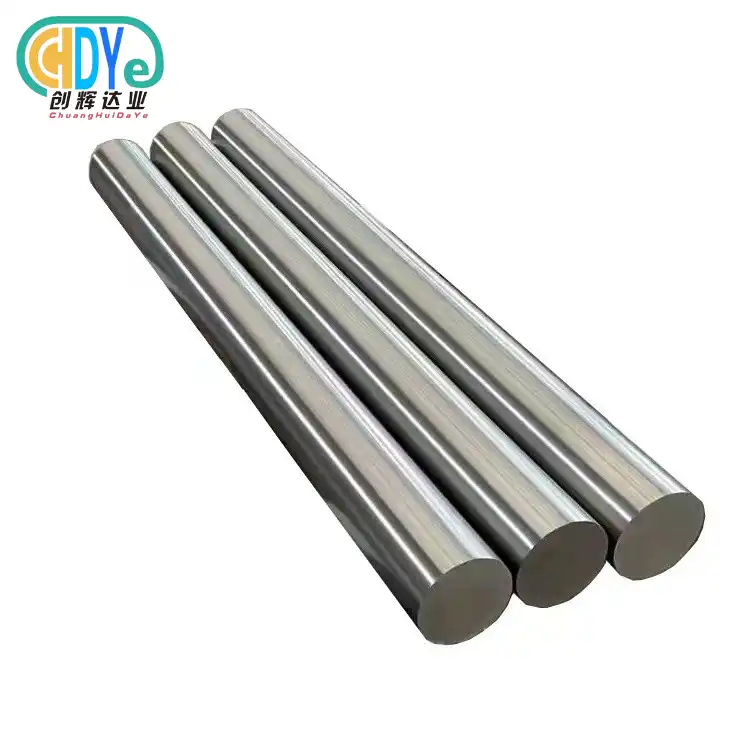

ASTM B 265 Titanium Sheet

Standard: ASTM B 265

Production process: cold rolled

specification: as your requirements,we can cut the whole sheet for your required size and no exra cutting charge

Product Overview

ASTM B265 titanium sheet is produced according to the ASTM B265 standard, which is developed by the American Society for Testing and Materials (ASTM) and specifies requirements for the chemical composition, mechanical properties, corrosion resistance, and other aspects of titanium and titanium alloys. The ASTM B265 standard is applicable to titanium and titanium alloy materials used in the manufacturing of pressure vessels, ships, aerospace, chemical, power and other fields.

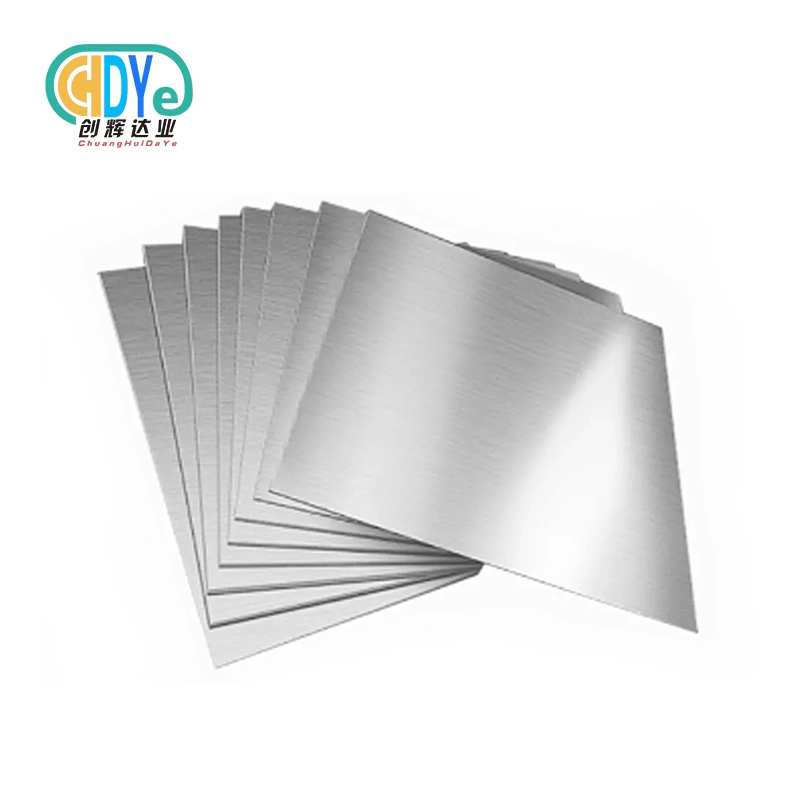

Technical Specifications

1.Grade: Gr1 Gr2 Gr3 Gr4 Gr5 Gr7 Gr9 Gr12 Gr23

2.Standard: ASTM B 265

3.Production process: cold rolled

4.Specification: as your requirements,we can cut the whole sheet for your required size and no exra cutting charge

| Parameter | Specification / Range | Description |

|---|---|---|

| Material | Commercially Pure Titanium / Titanium Alloy | CP-Ti or Ti-Alloy per ASTM B 265 |

| Grade | Gr1, Gr2, Gr3, Gr5 (Ti-6Al-4V) | Options for different mechanical requirements |

| Standards | ASTM B 265, ISO 5832-2, GB/T 3621 | Widely recognized for global industrial use |

| Thickness | 0.3 – 50 mm | Supports both thin and medium gauge industrial applications |

| Width | ≤ 1500 mm | Custom widths available for bulk orders |

| Length | ≤ 6000 mm | Cut-to-size service for batch procurement |

| Surface Finish | Mill finish, Pickled, Brushed, Polished | Industrial or aesthetic finishes |

| Density | 4.51 g/cm³ | Lightweight material for structural efficiency |

| Tensile Strength | 240 – 950 MPa | Depending on grade and alloy selection |

| Yield Strength | 170 – 880 MPa | Suitable for forming or load-bearing applications |

| Elongation | ≥ 10 – 25% | High ductility ensures bending, rolling, stamping capability |

| Heat Treatment | Annealed / Solution Treated | Enhances corrosion resistance and workability |

Chemical composition and mechanical properties

The ASTM B265 standard provides detailed regulations on the chemical composition of titanium sheets. The mechanical performance indicators of titanium alloys include tensile strength, yield strength, and elongation. Depending on the material specifications and applications, their mechanical performance indicators also vary. Generally speaking, titanium alloys have the characteristics of high strength, high rigidity, and good corrosion resistance.

Physical constants and thermal properties

|

Density |

4,51g/cm² |

|

Melting point |

1670°C |

|

Beta transus temperature |

920 ± 4°C |

|

Thermal conductivity at 20°C |

16 W/ m°C |

Typical mechanical properties (at room temperature for ASTM B265)

|

Yield strength |

min. 275, max. 450 MPa |

|

Tensile strength |

min. 345 MPa |

|

Elongation |

min. 20% |

Key Features and Benefits

- ASTM Standard Compliance: Ensures reliable chemical composition, mechanical performance, and dimensional accuracy.

- Corrosion Resistance: Resistant to seawater, chemical media, and oxidizing environments.

- Excellent Strength-to-Weight Ratio: Durable yet lightweight, suitable for industrial fabrication.

- High Ductility: Easy to cut, weld, bend, roll, or stamp for batch processing.

- Consistent Batch Quality: Every sheet undergoes thickness, flatness, and mechanical property inspection.

- Bulk Production Ready: Optimized for wholesale orders and industrial-scale fabrication.

Corrosion resistance performance

Titanium sheets have excellent corrosion resistance in most corrosive media, especially in neutral and oxidizing media. For example, titanium exhibits good corrosion resistance in solutions such as nitric acid, hydrochloric acid, sulfuric acid, and sodium hydroxide. However, titanium cannot resist the corrosive effect of hydrofluoric acid and has poor corrosion resistance in boiling sodium hydroxide solution.

Manufacturing & Processing Capability

Sheets are manufactured using vacuum melting, forging, precision hot and cold rolling, and annealing. Advanced facilities include electron beam furnaces, CNC rolling machines, shearing equipment, and annealing ovens. Each sheet undergoes:

- Thickness measurement and flatness inspection

- Surface quality verification

- Mechanical property testing

- Batch-level traceability for repeatable performance

- We provide both standard and customized sizes, suitable for large-scale industrial orders.

|

|

|

|

|

|

|

|

Quality Assurance

- ASTM Compliance: Ensures chemical composition, mechanical properties, and dimensional accuracy.

- Non-Destructive Testing: Ultrasonic inspection guarantees defect-free sheets.

- Batch Traceability: Mill Test Reports with batch numbers and production dates.

- ISO Certification: ISO 9001:2015 ensures international quality management compliance.

- Repeatable Performance: Suitable for bulk procurement requiring consistent material quality.

Application Advantages

- Chemical & Petrochemical Industry: Storage tanks, piping, heat exchangers, and reaction vessels.

- Marine Applications: Shipbuilding, offshore platforms, and desalination systems.

- Aerospace Components: Panels, structural brackets, reinforcement members.

- Medical Industry: Surgical instruments, implants, and laboratory equipment.

- Energy & Environmental Systems: Condensers, pipelines, and chemical machinery.

- Electronics & High-Purity Equipment: Semiconductor and laboratory precision components.

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

R&D and Customization

Our R&D team focuses on practical improvements for ASTM B 265 sheets:

- Purity & Impurity Control: Minimizes oxygen, nitrogen, and iron for better corrosion resistance.

- Surface & Flatness Optimization: Pickling, polishing, and brushing reduce defects.

- Thickness Consistency: Precision cold-rolling and annealing maintain uniform gauge.

- Prototype & Batch Testing: Ensures bulk order performance and quality stability.

- Technical Support: Guides fabrication, welding, stamping, and forming for batch production projects.

Packaging & Logistics

Sheets are packed with anti-rust film, foam padding, and export-standard wooden crates. Labels include material grade, dimensions, and batch numbers. Delivery options include air, sea, and land shipping for safe and timely distribution.

|

|

|

|

|

|

|

|

|

|

|

|

OEM & Customization Services

We provide:

- Custom thickness, width, and length for bulk orders

- Specific surface finishes and mechanical properties

- Prototype and small-batch production for industrial projects

- Technical consultation for fabrication, welding, and assembly

Global Market & Cooperation

ASTM B 265 Titanium Sheets are exported to over 50 countries, including USA, Germany, France, Mexico, South Korea, and Singapore. We maintain long-term partnerships with distributors, manufacturers, and industrial end-users, ensuring consistent supply and technical support for large orders.

Feedback from customers

Why Choose Us :

1. You can get the perfect material according to your requirement at the least possible price.

2. We offer FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

5. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

Sample order is supported!

|

|

|

|

|

|

ASTM B 265 Titanium Sheet Transaction Process

1.First contact us to provide the grade, size ,quantity and standard or any special requirements.

2.we will reply you the quotation with delivery time in 3 hours.

3.reach an agreement then buyer arrange the prepayment.

4. when we get your payment we will arrange production asap and share you the production progress.

5.when production finished, will give buyer the actual weight of the products, then the buyer arrange balance payment.

6. Arrange shipment according to the most economical form we have agreed on

7.Meanwhile send buyer the material certificate.

8. Regular after-sales service to know the actual product usage.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Chdymetal have more than 30year's experience in Non-ferrous metal industry, ASTM B 265 Titanium Sheet is one of our main products, we have common size in stock all year round and we can arrange 1-3days quick delivery.

Welcome to contact us for more information: info@chdymetal.com/ Mob.: 86-18049386902

Learn about our latest products and discounts through SMS or email