- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

pure tantalum sheet/plate

2.Standard: ASTM B708 3.Type: sheet, plate, foil, strip

Product production

Looking for exceptional pure tantalum sheet/plate for your industrial applications? You've come to the right place. At Shaanxi Chuanghui Daye Metal Material Co., Ltd., we specialize in manufacturing high-quality tantalum sheets and plates that meet the most demanding industry standards. Our products offer superior corrosion resistance, exceptional durability, and outstanding performance across various applications. With over 30 years of experience in the rare metal industry, we deliver pure tantalum sheet/plate solutions that exceed your expectations.

Key Features and Benefits

Our tantalum sheets and plates deliver remarkable performance characteristics that make them ideal for critical applications. The exceptional corrosion resistance ensures long-lasting performance even in harsh chemical environments. You'll benefit from the superior biocompatibility, making these materials perfect for medical device manufacturing.

The high melting point and thermal stability provide reliable performance in extreme temperature conditions. Our products offer excellent electrical conductivity properties, essential for electronic applications. The non-reactive nature ensures compatibility with various chemical processes without contamination concerns.

Technical Specifications

| Property | Specification |

|---|---|

| Alloy Composition | Ta >99.9% |

| Thickness Range | 0.5–20 mm |

| Density | 16.65 g/cm³ |

| Tensile Strength | 200–300 MPa |

| Melting Point | 3017°C |

| Standard | ASTM B708 |

| Certificate | ISO 9001:2015 |

| Condition | Annealed |

| Production time | Normal production time is 10-15days |

| Payment term | 30%TT in advance, 70% balance before shipment |

Chemical composition

|

Grade |

Main component |

Impurity content(≤) |

||||||||||

|

Ta |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Nb |

O |

C |

H |

N |

|

|

Ta1 |

Residual |

0.005 |

0.005 |

0.002 |

0.01 |

0.01 |

0.002 |

0.03 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

Ta2 |

Residual |

0.03 |

0.02 |

0.005 |

0.04 |

0.03 |

0.005 |

0.1 |

0.02 |

0.01 |

0.0015 |

0.01 |

Available Grades and Materials

We offer various grades to meet your specific requirements. Our standard grade provides excellent general-purpose performance for most industrial applications. High-purity grades are available for specialized electronic and medical applications requiring enhanced performance characteristics.

Custom alloy compositions can be developed according to your unique specifications. All materials undergo rigorous quality testing to ensure consistent performance and reliability.

Tantalum and Tantalum Alloy UNS Grade

R05200, unalloyed tantalum, electron-beam furnace vacuum-arc melt, or both

R05400, unalloyed tantalum, powder-metallurgy consolidation.

R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

R05252, tantalum alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace vacuum-arc melt, or both.

R05240, tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

Other tantalum alloys also can be customized.

Manufacturing Process

Our advanced manufacturing process begins with premium raw materials sourced from certified suppliers. We employ state-of-the-art rolling and forming techniques to achieve precise dimensions and superior surface finish.

Heat treatment processes optimize the mechanical properties for your specific applications. Quality control checkpoints throughout production ensure consistent material properties. Final inspection and testing verify that every product meets our stringent quality standards.

|

|

|

|

|

|

|

|

Applications and Industries

Chemical processing industries rely on our tantalum products for reactor vessels, heat exchangers, and corrosion-resistant components. The electronics sector uses our materials for capacitor manufacturing, semiconductor applications, and electronic component production.

Medical device manufacturers choose our biocompatible materials for implants, surgical instruments, and diagnostic equipment. Aerospace applications include jet engine components, nuclear reactor parts, and high-temperature structural elements.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

Standard thickness tolerances range from ±0.05mm for thin sheets to ±0.5mm for thicker plates. Width tolerances typically maintain ±2mm precision across the full range. Length cutting accuracy stays within ±5mm for most standard sizes.

Custom dimensions are available to meet your specific project requirements. We can provide materials cut to exact specifications, reducing your processing time and material waste.

Product Features in Detail

The dark blue-gray metallic appearance provides easy visual identification. Surface finishes range from mill finish to polished surfaces depending on your application needs. Edge conditions can be specified as sheared, machined, or deburred according to your requirements.

Flatness specifications ensure proper fit and performance in your assemblies. The uniform grain structure provides consistent mechanical properties throughout the material thickness.

Quality Assurance and Testing

Every batch undergoes comprehensive chemical composition analysis to verify purity levels. Mechanical property testing confirms tensile strength, yield strength, and elongation values. Dimensional inspection ensures all products meet specified tolerances.

Certificates of compliance accompany each shipment, providing complete traceability. Our quality management system follows international standards to ensure consistent product quality.

OEM & Customization Services

We work closely with you to develop custom solutions for unique applications. Our engineering team provides technical support throughout the design process. Prototype development services help validate designs before full production.

Value-added services include precision cutting, surface treatments, and forming operations. We can deliver ready-to-use components that reduce your manufacturing time and costs.

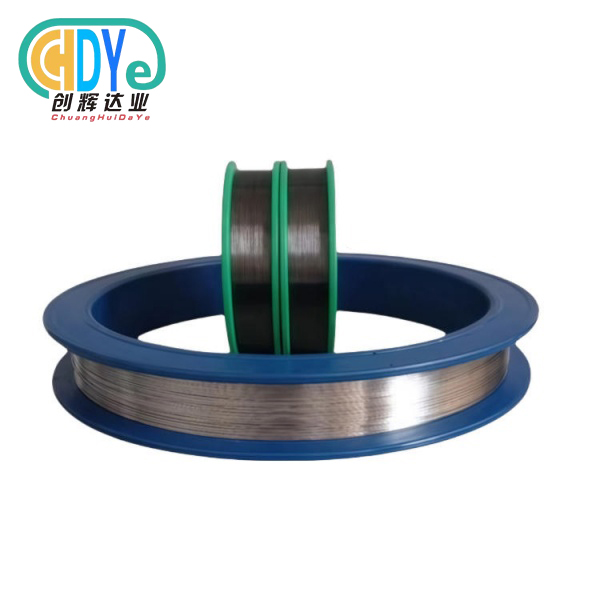

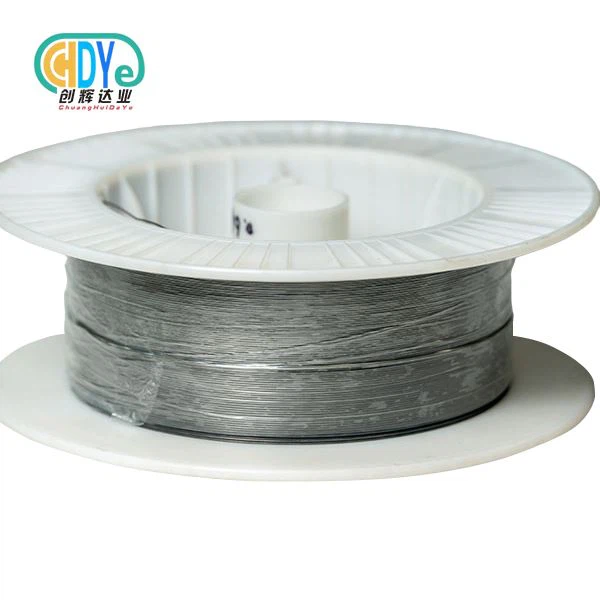

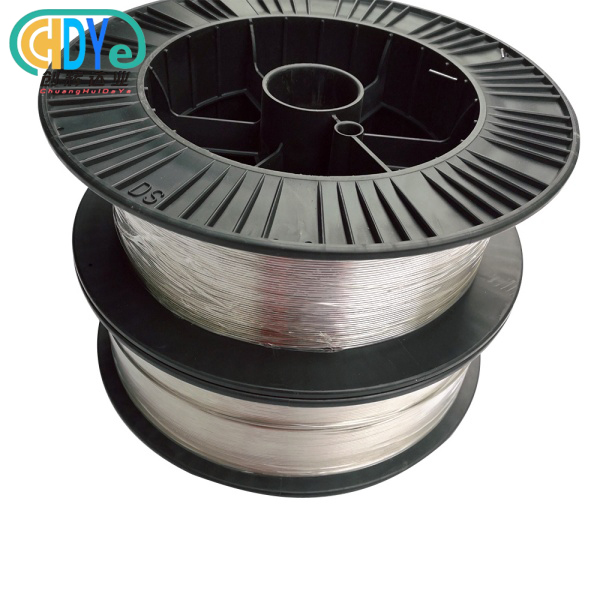

Packaging and Shipping

Protective packaging prevents damage during transportation while maintaining material integrity. Moisture-resistant materials protect against environmental contamination. Proper labeling ensures easy identification and inventory management.

We coordinate shipping worldwide through reliable logistics partners. Tracking information keeps you informed throughout the delivery process. Our products reach customers in over 50 countries with consistent quality and on-time delivery.

|

|

|

|

|

|

|

|

|

Why Choose Us

Located in China's "Titanium Capital," we have access to premium raw materials and specialized manufacturing expertise. Our founder's 30+ years of rare metal industry experience ensures deep technical knowledge and reliable solutions.

We focus on building long-term partnerships through competitive pricing, superior quality, and exceptional customer service. Our commitment to continuous improvement drives innovation in products and processes.

|

|

|

FAQs

Q: What makes pure tantalum sheet/plate ideal for chemical applications?

A: The exceptional corrosion resistance and non-reactive nature provide long-lasting performance in aggressive chemical environments.

Q: Can you provide custom sizes beyond standard dimensions?

A: Yes, we offer custom cutting and forming services to meet your specific dimensional requirements.

Q: What certifications do your products include?

A: Each shipment includes certificates of compliance with complete chemical and mechanical property documentation.

Contact Us

Ready to discuss your tantalum material requirements? Our technical team is here to help you select the right solution for your application. Contact us today at info@chdymetal.com to request quotes, technical specifications, or additional information about our pure tantalum sheet/plate products.

Learn about our latest products and discounts through SMS or email