- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Tungsten Alloy Bar

Product Introduction

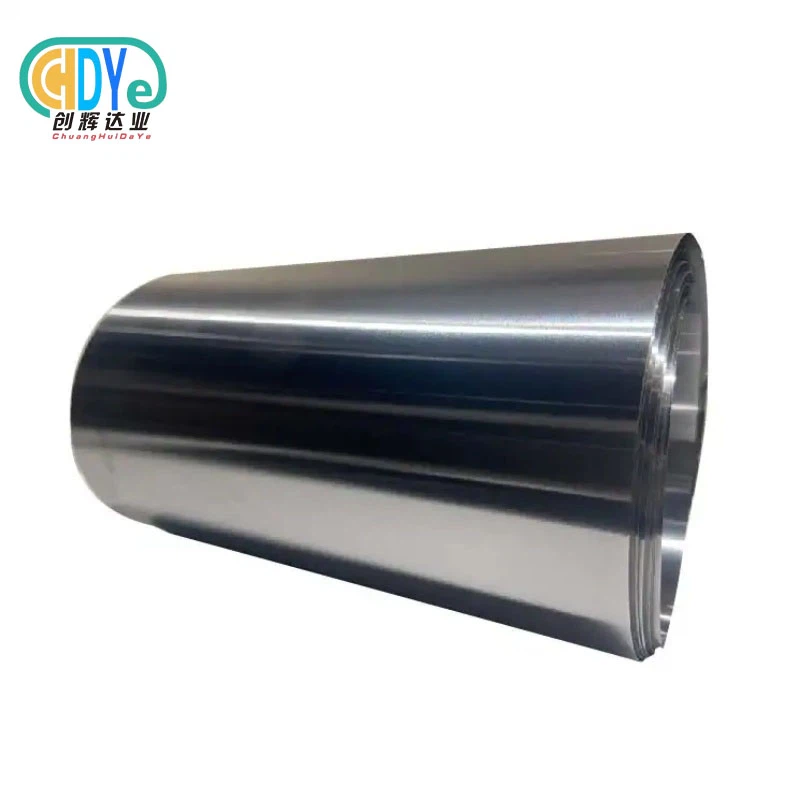

The Tungsten Alloy Bar produced by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is designed to meet the demanding requirements of high-performance applications. Made from tungsten blended with nickel, iron, or copper, this material offers an ideal combination of density, strength, and machinability. With a density ranging from 16.5 to 18.75 g/cm³ and excellent thermal and electrical conductivity, the Tungsten alloy rod is widely recognized for its superior mechanical performance in extreme environments. It maintains stability under high temperature and stress conditions, making it suitable for aerospace, defense, medical, and industrial use. Each bar is available in sintered, forged, or precision-machined form according to ASTM and GB standards.

Tungsten alloy rod have special properties such as low thermal expansion and good thermal conductivity, sufficient electrical resistance, and high elastic modulus. Therefore, tungsten alloy rod are widely used in various fields. Such as support wires, import wires, printer needles, various electrodes and quartz furnaces, filaments, high-speed tools, automotive automation products, sputtering targets.

|

Name |

tungsten alloy bar |

|

Shape |

round shape or as your request |

|

Material |

Tungsten and copper alloy |

|

Size |

Customized |

|

Melting point |

3410 Degree Centigrade |

|

Certificate |

ISO9001:2015 |

|

Density |

11.85.85-16.75g/cm3 |

|

Surface |

black, polished, sintering, forging, machining |

|

Grade |

W90/Cu10, W80/Cu20, W70/Cu30 |

|

Service |

Welcome OEM&ODM.The size and purity can be customized as requiremets. |

|

Application |

Industry,electric light source, electric vacuum industry. |

Chemical composition

|

GRADE |

CHEMICAL CONTENT |

DENSITY |

HARDNESS |

|

|

|

||

|

Cu |

IMPURITY ≤ |

W |

g/cm3 ≥ |

HB Kgf/mm2 ≥ |

μΩ.cm ≤ |

% ≥ |

MPa ≥ |

|

|

W50/Cu50 |

50±2.0 |

0.5 |

BAL |

11.85 |

115 |

3.2 |

54 |

-- |

|

W55/Cu45 |

45±2.0 |

0.5 |

BAL |

12.30 |

125 |

3.5 |

49 |

-- |

|

W60/Cu40 |

40±2.0 |

0.5 |

BAL |

12.75 |

140 |

3.7 |

47 |

-- |

|

W65/Cu35 |

35±2.0 |

0.5 |

BAL |

13.30 |

155 |

3.9 |

44 |

-- |

|

W70/Cu30 |

30±2.0 |

0.5 |

BAL |

13.80 |

175 |

4.1 |

42 |

790 |

|

W75/Cu25 |

25±2.0 |

0.5 |

BAL |

14.50 |

195 |

4.5 |

38 |

885 |

|

W80/Cu20 |

20±2.0 |

0.5 |

BAL |

15.15 |

220 |

5.0 |

34 |

980 |

|

W85/Cu15 |

15±2.0 |

0.5 |

BAL |

15.90 |

240 |

5.7 |

30 |

1080 |

|

W90/Cu10 |

10±2.0 |

0.5 |

BAL |

16.75 |

260 |

6.5 |

27 |

1160 |

Application Advantages

1)Mechanical processing: In the process of casting cannon barrels, tungsten alloy bars are often used to make drill rods, which are drilled and expanded with a single point cutting tool to obtain precise diameter circular holes. In addition, tungsten alloy rods can also be used for cutting conical circular holes.

2) Aerospace: Tungsten alloy rods are widely used in the aerospace industry, such as as as counterweights and balancing components for aircraft control surfaces and rotor blades, counterweights for navigation systems, and balancing components for flywheels and turbine engine crankshafts. After mixing with heat-resistant steel, tungsten alloy rods can be used to manufacture high-temperature resistant components such as guns, cannons, rockets, satellites, aircraft, and ships.

3) Other applications: Tungsten alloy rods are also used for nuclear radiation shielding, gyroscope rotors, high-temperature resistant tools, etc. In addition, tungsten alloy rods have characteristics such as high density, high melting point, high hardness, high strength, low thermal expansion coefficient, high elastic modulus, wear resistance, high temperature resistance, and good electrical and thermal conductivity, making them widely used in multiple fields.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

The production of Tungsten Alloy Bar at Shaanxi Chuanghui Daye follows a comprehensive metallurgical process:

- Powder Preparation: Selection of high-purity tungsten and alloying powders.

- Mixing and Pressing: Uniform powder blending and isostatic pressing for density uniformity.

- Sintering: High-temperature vacuum or hydrogen sintering ensures strong bonding and high density.

- Forging and Rolling: Enhances mechanical strength and grain structure.

- Machining and Finishing: Precision turning, milling, and grinding to meet tolerance requirements.

- Inspection and Packaging: Full inspection before export-standard packaging and shipment.

Every step is monitored under strict process control to ensure consistency and performance.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality is the foundation of Shaanxi Chuanghui Daye’s operations. The Tungsten Alloy Bar undergoes multiple quality assurance procedures:

- Material Verification: Each batch of raw tungsten and alloying elements is tested for purity and composition.

- Dimensional Inspection: Precision measurements ensure tolerance accuracy within ±0.02 mm.

- Density and Hardness Tests: Guarantee consistency and uniform compaction.

- Ultrasonic Examination: Detects internal voids or defects.

- Final Quality Review: Each product is delivered with a material test report and traceable certification.

These steps ensure compliance with ISO 9001:2015 and international material standards.

R&D and Customization

With an experienced technical team and over 30 years of rare metal expertise, Shaanxi Chuanghui Daye continues to advance tungsten alloy development. R&D focuses on:

- High-density alloys with improved tensile strength and hardness.

- Tailored compositions for enhanced wear resistance or radiation absorption.

- Precision machining for complex geometries and tight tolerances.

- Custom thermal treatment and surface finishing solutions.

Packaging & Global Logistics

Each Tungsten Alloy Bar is securely packed and delivered through reliable global logistics channels:

- Packaging: Vacuum-sealed or anti-rust wrapping, foam protection, and export-standard wooden cases.

- Labeling: Clear marking with size, batch number, and alloy grade.

- Logistics: Safe and efficient transportation by air, sea, or land with global tracking.

The company’s export experience across 50+ markets ensures that every shipment arrives safely, meeting the strictest delivery schedules.

|

|

|

|

|

|

|

|

|

|

|

|

OEM & Customization Service

Shaanxi Chuanghui Daye provides comprehensive OEM and ODM services for clients worldwide:

- Production according to customer blueprints and drawings.

- Tailored material composition and density control.

- Prototype and small-batch production support.

- Engineering consultation for design and application optimization.

- Confidential cooperation and after-sales technical support.

Our goal is to deliver customized tungsten alloy products that perfectly fit client specifications and operational needs.

Inspection Process

- Visual Examination: Checking for surface defects and uniformity.

- Dimensional Verification: Ensuring precision with advanced measuring instruments.

- Mechanical Testing: Verifying tensile strength, hardness, and ductility.

- Ultrasonic and Density Testing: Ensuring structural integrity and uniform compaction.

- Final Certification: Providing full traceability with inspection records and compliance certificates.

Only products passing all quality criteria are approved for shipment.

Why Choose Us

- 30+ Years of Experience: Proven expertise in refractory metal production.

- Full Material Range: Tungsten, molybdenum, tantalum, niobium, and titanium series available.

- ISO 9001:2015 Certified: Comprehensive quality management across all processes.

- Advanced Equipment: Electron beam furnaces, forging lines, and precision machining centers.

- Global Reach: Export to over 50 countries and regions.

- Custom Solutions: Support for OEM/ODM projects and technical consultation.

- Fast Delivery: Standard products available within 7 days for urgent orders.

Choosing Shaanxi Chuanghui Daye ensures consistent quality, competitive pricing, and reliable global service.

|

|

|

|

|

|

FAQs

Q1: What is the density of your tungsten alloy rod?

A1: The density typically ranges from 16.5 to 18.75 g/cm³, depending on the alloy composition.

Q2: Can you produce custom sizes and shapes?

A2: Yes, we manufacture Tungsten Alloy Rod according to customer drawings and dimensional requirements.

Q3: What standards do your products meet?

A3: Our tungsten alloy products comply with ASTM B777, AMS-T-21014, and GB/T standards.

Q4: What are the available surface finishes?

A4: Ground, polished, and centerless-finished surfaces are available based on application needs.

Q5: How is packaging handled for international transport?

A5: Each bar is vacuum-packed and placed in export-standard wooden boxes to ensure protection during transit.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email