- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

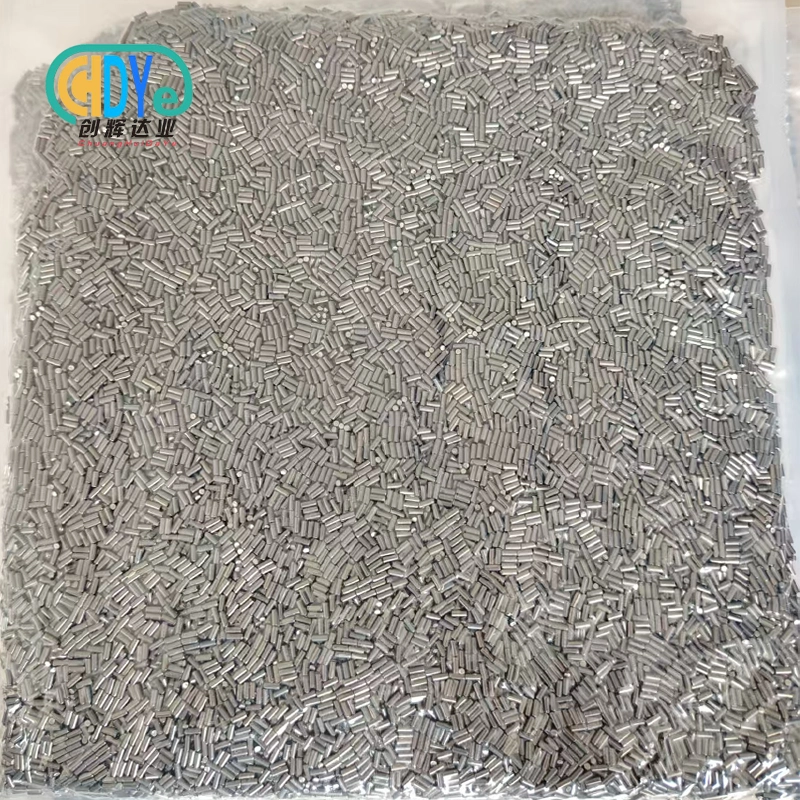

molybdenum spray wire

2.Surface: Black or alkali washing

3.Certificate: ISO9001:2015

4.Standard:ASTM B 387

Product Introduction

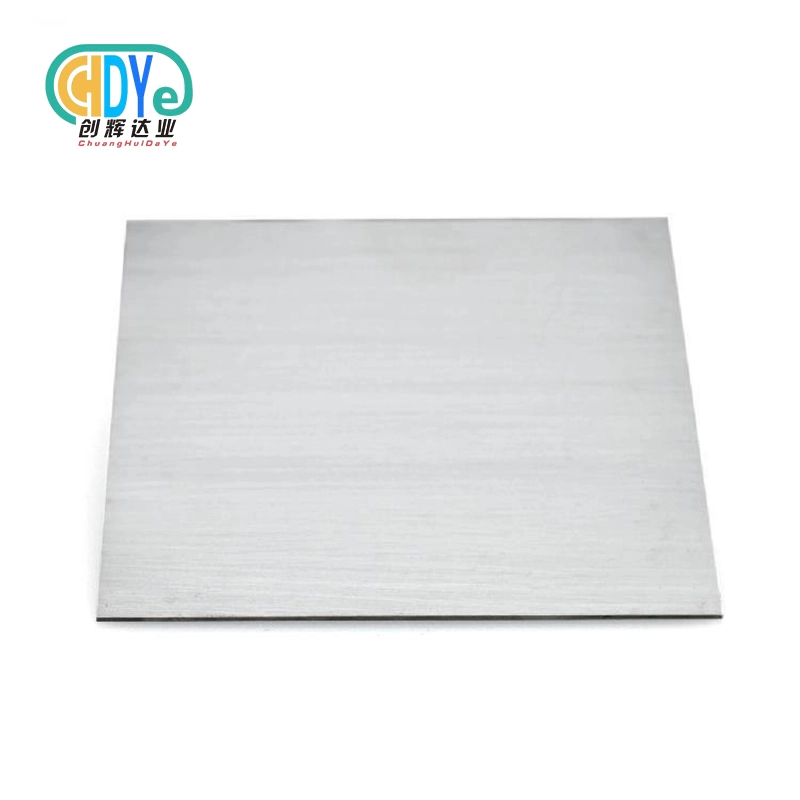

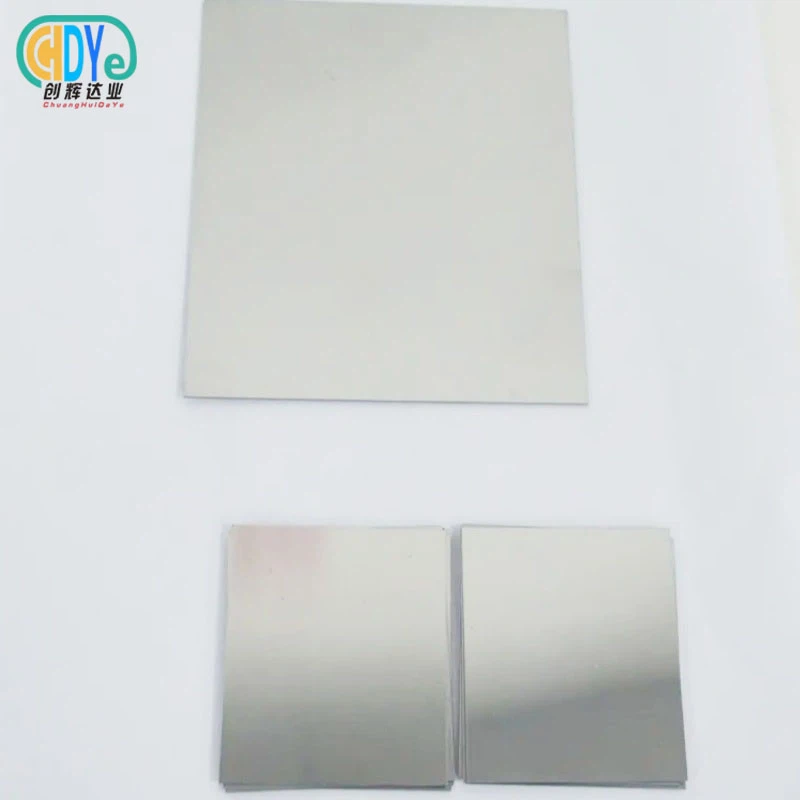

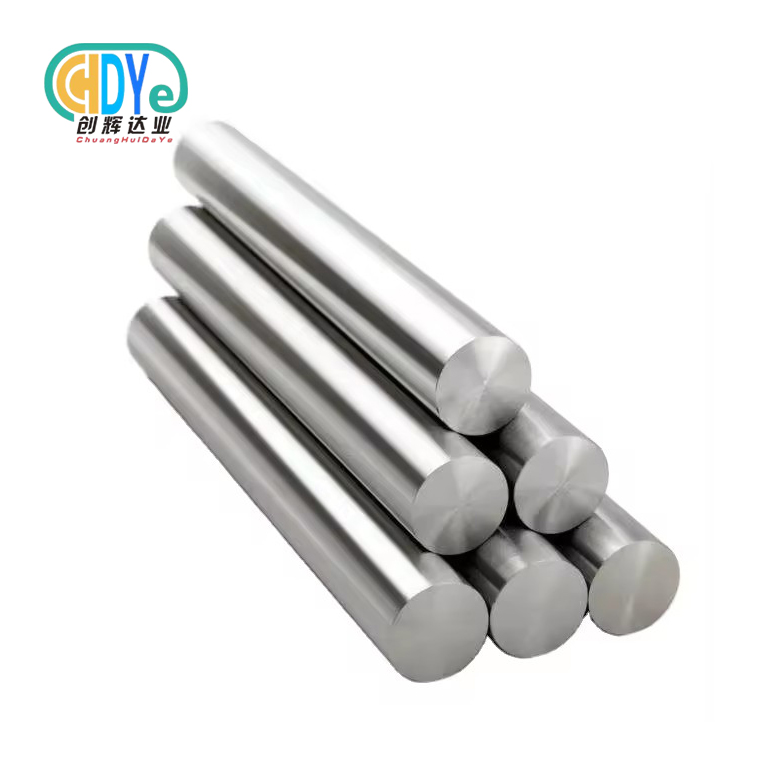

When you need reliable thermal spray materials for demanding industrial applications, our premium molybdenum spray wire delivers exceptional performance and durability. Manufactured with over 99.95% pure molybdenum, this high-quality wire offers superior thermal conductivity, excellent corrosion resistance, and outstanding mechanical properties. Our thermal spray wire is specifically engineered for twin wire arc spray systems, providing consistent results in coating applications across multiple industries. With diameters ranging from 0.05mm to 5mm and lengths up to 1000mm, you get the flexibility to meet your specific project requirements.

Key Features and Benefits

- Exceptional Purity: Over 99.95% molybdenum content ensures consistent performance

- Superior Heat Resistance: Withstands extreme temperatures up to 2623°C

- Excellent Corrosion Protection: Creates durable protective coatings

- Versatile Applications: Perfect for wear resistance, surface restoration, and protective coatings

- Consistent Quality: Stringent manufacturing process guarantees uniform properties

- Cost-Effective Solution: Long-lasting performance reduces maintenance costs

Technical Specifications

| Property | Specification |

|---|---|

| Alloy Composition | Mo >99.95% |

| Diameter Range | 0.05–5 mm |

| Maximum Length | up to 1000 mm |

| Density | 10.2 g/cm³ |

| Tensile Strength | 500–700 MPa |

| Melting Point | 2623°C |

| Application Method | Thermal spray |

| Certification | ISO9001:2015 |

| Surface | Black Wire, Bright Wire |

| Technology Process | Forged, Drawn, Polished |

| Delivery time | 10-15days according to your quantity |

Chemical composition

|

Grade |

Chief constituent % |

The impurity content is not more than % |

|||||||||||

|

Mo |

Ti |

Zr |

C |

Al |

Ca |

Fe |

Mg |

Ni |

Si |

C |

N |

O |

|

|

Mo1 |

Balance |

- |

- |

- |

0.002 |

0.002 |

0.010 |

0.002 |

0.005 |

0.01 |

0.01 |

0.003 |

0.008 |

|

Mo2 |

Balance |

- |

- |

- |

0.005 |

0.004 |

0.015 |

0.005 |

0.005 |

0.01 |

0.02 |

0.003 |

0.020 |

|

TZM |

|

0.4- |

0.06- |

0.01- |

0.002 |

0.002 |

0.01 |

0.001 |

0.005 |

0.005 |

- |

0.002 |

0.05 |

Available Grades and Materials

Our molybdenum wire products come in several grades to meet your specific requirements:

- Pure Molybdenum Wire: Standard grade for general thermal spray applications

- High-Density Molybdenum: Enhanced performance for demanding environments

- Custom Alloy Options: Tailored compositions available upon request

Manufacturing Process

We follow a comprehensive manufacturing process to ensure consistent quality. Starting with high-purity molybdenum powder, we press the material into ingots and draw them down through multiple process steps. Our controlled manufacturing environment maintains strict quality standards throughout production. Each batch undergoes rigorous testing to verify chemical composition and mechanical properties.

|

|

|

|

|

|

|

|

Applications and Industries

Your thermal spray projects benefit from our wire's versatility across numerous applications:

- Aerospace Components: Surface restoration and protective coatings

- Automotive Industry: Wear-resistant coatings for engine components

- Chemical Processing: Corrosion-resistant surface treatments

- Medical Equipment: Biocompatible coating applications

- Electronics: Conductive and protective surface treatments

- Energy Sector: High-temperature component protection

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain tight dimensional tolerances to ensure optimal performance in your spray equipment. Wire diameter tolerance is ±0.01mm for diameters above 1mm and ±0.005mm for smaller diameters. Length tolerances are kept within ±2mm for standard products.

Product Features in Detail

The superior properties of our molybdenum spray wire make it ideal for challenging applications. The high melting point ensures stability during thermal spray processes, while excellent thermal conductivity provides efficient heat transfer. The wire's ductility allows for smooth feeding through spray equipment without breakage.

Quality Assurance and Testing

Every batch undergoes comprehensive testing including chemical analysis, tensile testing, and dimensional verification. We maintain detailed quality records and provide certificates of analysis with each shipment. Our quality management system ensures consistent product performance.

|

|

|

OEM & Customization Services

We understand that your applications may require specific wire characteristics. Our engineering team works closely with you to develop custom molybdenum spray wire solutions. Whether you need modified compositions, special packaging, or unique dimensions, we can accommodate your requirements.

Packaging and Shipping

Our products are carefully packaged to prevent contamination and damage during transit. Standard packaging includes protective wrapping and cushioning materials. We offer various shipping options to meet your delivery requirements worldwide.

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us

With over 30 years of experience in rare metals, Shaanxi Chuanghui Daye Metal Material Co., Ltd. brings unmatched expertise to every order. Located in China's "Titanium Capital," we have access to premium raw materials and advanced manufacturing facilities. Our products serve customers in over 50 countries, demonstrating our commitment to quality and reliability.

|

|

|

|

|

|

FAQs

Q: What makes your molybdenum spray wire different from competitors?

A: Our wire features over 99.95% purity and consistent dimensional tolerances, ensuring reliable performance in thermal spray applications.

Q: Can you provide custom wire diameters?

A: Yes, we can manufacture custom diameters within our production capabilities to meet your specific requirements.

Q: What is the typical lead time for orders?

A: Standard products typically ship within 1-2weeks, while custom orders may require 2-3weeks depending on specifications.

Contact Us

Ready to enhance your thermal spray applications with premium molybdenum wire? Contact our technical team today to discuss your requirements and receive a customized quote.

Email: info@chdymetal.com

Mobile/what's app.: 86-18049386902

Our experienced professionals are ready to help you select the right product for your specific applications and provide technical support throughout your project.

Learn about our latest products and discounts through SMS or email