- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

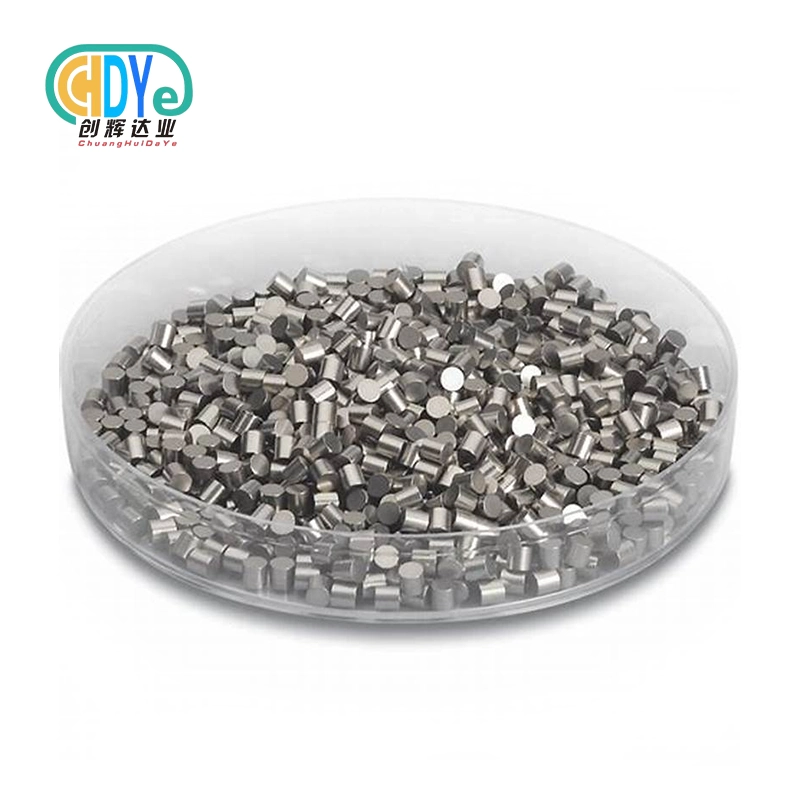

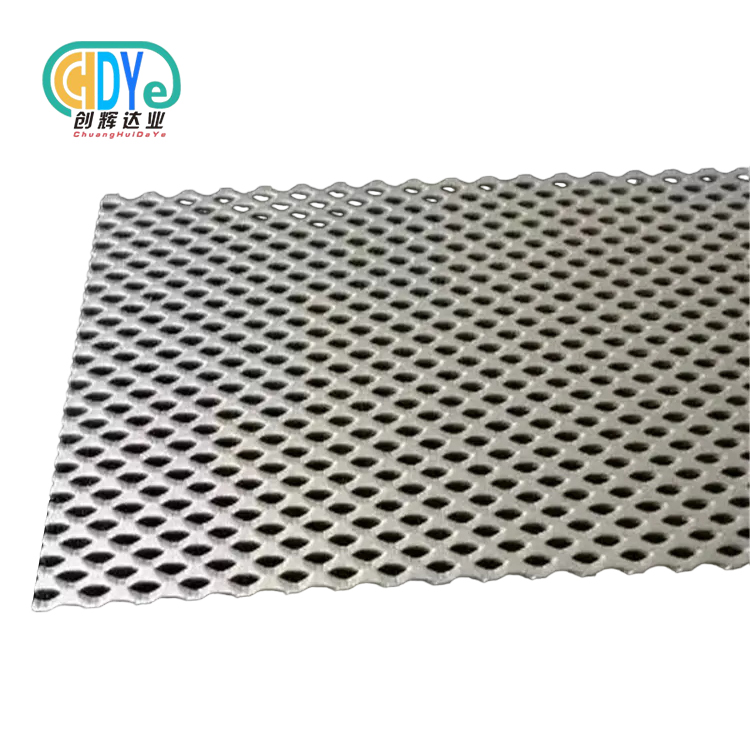

Pure Molybdenum Plate

2.Shape: Plate/Sheet/foil/strip

3.Size: Customized

4.Density: 10.28g/cm3

5.Standard: ASTM B 386

Product Introduction

The Pure Molybdenum Plate produced by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is manufactured from high-purity molybdenum powder through advanced vacuum sintering, rolling, and annealing processes. With its excellent strength, high melting point (2620°C), and superior thermal conductivity, the plate is ideal for applications requiring outstanding performance under high temperature and vacuum conditions. Each Pure Molybdenum Sheet meets international standards such as ASTM B386, GB/T 3876, and ISO 9001:2015, ensuring excellent dimensional accuracy, uniform grain structure, and stable mechanical properties.

The Molybdenum Plate is a metal plate with molybdenum as the main material, It is widely used in the construction of molds and parts furnaces, and the manufacture of parts in the electronics and semiconductor industries.

Product Name: pure Molybdenum Plate

Model Number: Mo1

Material: Molybdenum

Purity: 99.95%

Shape: Plate/Sheet

Size: Customized

Density: 10.28g/cm3

Standard: ASTM B 386

Application:

1.molybdenum plate has good corrosion resistance, and the surface comes with a layer of fine strong protective film, can well protect the matrix from corrosion.

2. molybdenum plate after oxidation and color can be used for casting aluminum alloy and processing plastic deformation aluminum alloy.

3. the strength of molybdenum plate is very high, and the strength will increase after a certain degree of cold processing.

4, molybdenum plate has good electrical conductivity, and the advantages of low density and easy processing.

Packing and shipping

Package: Usually it is standard wooden case for exporting,if it is very small and light,we will choose paper carton to pack them.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

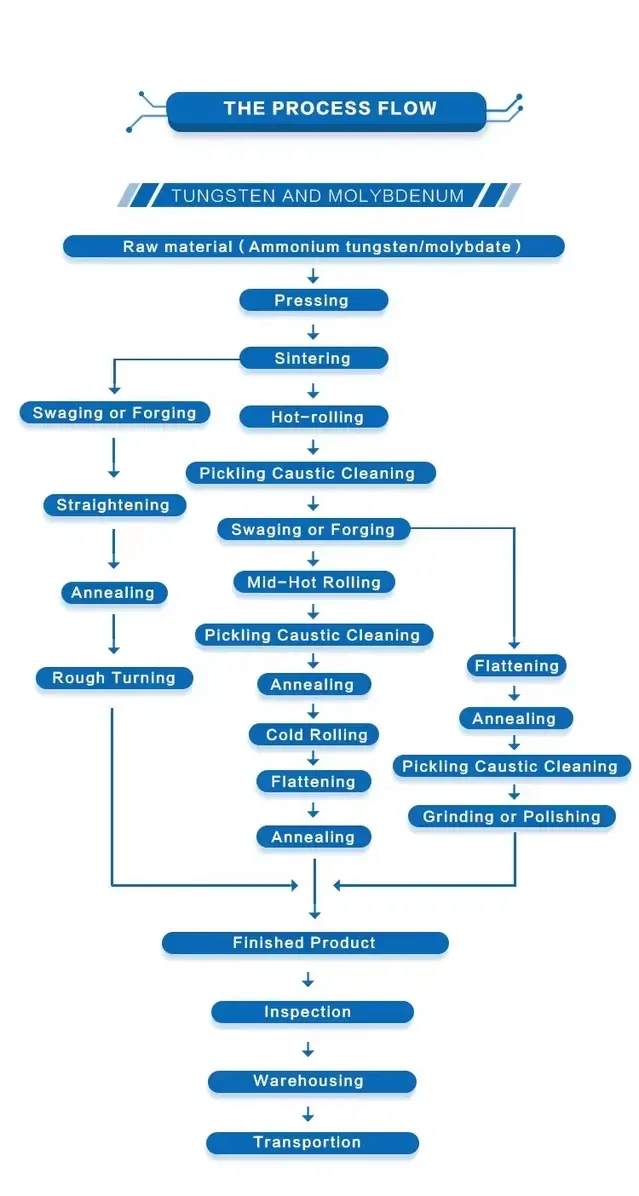

Manufacturing & Process Flow

The production of Pure Molybdenum Plate follows a strict and traceable process to ensure consistent purity and performance:

- Powder Preparation: Selection of high-purity molybdenum powder (≥99.95%).

- Pressing & Sintering: Vacuum sintering at high temperature to form a dense billet.

- Rolling & Annealing: Multiple hot and cold rolling operations with precise annealing treatment to achieve uniform thickness.

- Machining & Surface Finishing: Precision cutting, grinding, and polishing to achieve smooth surface and exact dimensions.

- Final Inspection & Packaging: 100% dimensional, surface, and purity inspection before shipment.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality assurance is the foundation of Shaanxi Chuanghui Daye. Our Pure Molybdenum Plate is subjected to a comprehensive quality control system that includes:

- Raw Material Testing: Purity verification by spectrometer and impurity analysis.

- Dimensional Accuracy Inspection: Using micrometers and coordinate measuring machines (CMM).

- Mechanical Property Testing: Hardness, density, and tensile strength verification.

- Surface Finish Examination: Ensuring smoothness and absence of cracks or oxidation.

All procedures strictly comply with ISO 9001:2015 standards to guarantee stable and reliable product quality.

R&D and Customization

Shaanxi Chuanghui Daye’s R&D team continuously optimizes molybdenum processing technology to enhance the mechanical strength and surface precision of the Pure Molybdenum Plate. We provide customized development based on client requirements, including:

- Tailored thickness, width, and length.

- Custom mechanical properties for specific environments.

- Enhanced flatness and microstructure control for vacuum applications.

- Surface treatment options such as grinding or chemical polishing.

Packaging & Global Logistics

Each Pure Molybdenum Plate is packaged according to international export standards to ensure safe and damage-free delivery:

- Inner Packaging: Anti-rust film and shock-absorbing foam.

- Outer Packaging: Export-standard wooden box with humidity protection.

- Labeling: Clear identification of grade, size, heat number, and batch.

Shipments are managed through reliable air, sea, and land transportation partners, ensuring fast and secure delivery to over 50 global markets including the United States, Germany, Korea, and Singapore.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye provides full OEM and ODM services for global customers:

- Manufacturing according to drawings or samples.

- Custom grades and dimensions.

- Prototype and batch production.

- Technical consultation and after-sales service.

Our professional engineering team works closely with clients to achieve precise technical performance and cost-effective solutions.

Inspection Process

To ensure every Pure Molybdenum Plate meets customer expectations, our inspection process covers:

- Incoming Material Inspection – Chemical composition analysis and impurity control.

- In-Process Supervision – Rolling, annealing, and surface monitoring.

- Final Quality Verification – Mechanical, dimensional, and visual tests.

- Packing Inspection – Labeling and protective verification before shipment.

Why Choose Us

- 30+ Years of Industry Expertise in refractory and rare metals.

- Comprehensive Quality Control certified under ISO 9001:2015.

- Advanced Equipment: Electron beam furnace, annealing furnace, precision rolling machine.

- Global Export Experience: Products shipped to over 50 countries.

- Customized Solutions: Flexible design, technical support, and OEM cooperation.

- Fast Delivery: Standard items ready within 7 days.

|

|

|

|

|

|

FAQs

Q1: What is the purity level of your Pure Molybdenum Plate?

A1: Our plates have a minimum purity of 99.95%, ensuring excellent performance in high-temperature environments.

Q2: Can you supply custom-sized molybdenum plates?

A2: Yes, we can produce customized sizes, thicknesses, and tolerances according to client drawings or technical specifications.

Q3: What is the typical delivery time?

A3: Standard sizes are available for immediate shipment; custom orders usually take 7–15 working days.

Q4: How do you ensure quality consistency?

A4: Each production stage is inspected and recorded, following ISO 9001:2015 standards, with a complete test report provided upon request.

Q5: Do you provide OEM service?

A5: Yes, OEM and ODM cooperation are fully supported, including product labeling and custom packaging.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email