- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

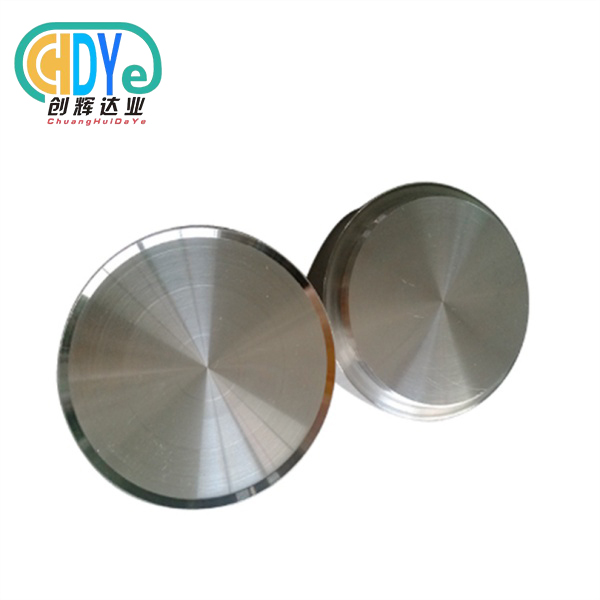

High Purity Tantalum Crucible

2.Specifications: Dia 50mm - 500mm, height 50mm - 600mm (customized supported)

3.Wall thickness: 1mm - 10mm

Product Introduction

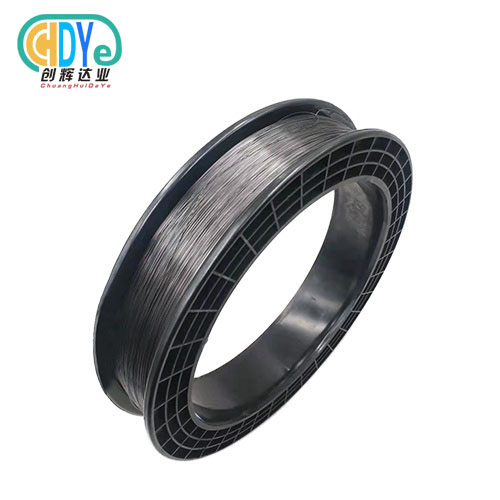

Tantalum crucibles are made of high-purity tantalum materials, which have excellent high temperature resistance, corrosion resistance and thermal conductivity. They are ideal containers for high-temperature melting, crystal growth and special material preparation. They are widely used in aerospace, semiconductors, optical glass and high-temperature alloys to meet the stringent needs of high-end industries.

Material: high purity tantalum (Ta≥99.95%)

Specifications: Dia 50mm - 500mm, height 50mm - 600mm (customized supported)

Wall thickness: 1mm - 10mm

Working temperature: ≤2200°C

Surface treatment: polishing, pickling or sandblasting

Standard : ASTM B365,

Certificate: ISO 9001:2015

High purity tantalum crucible Core advantages

Ultra-high temperature resistance: Tantalum has a melting point of up to 2996°C and can work stably in extremely high temperature environments.

Excellent corrosion resistance: It has strong corrosion resistance to acids, alkalis and molten metals and is suitable for a variety of chemical environments.

Excellent thermal conductivity: Ensures uniform heat distribution, improves smelting efficiency and material quality.

High-purity material: Tantalum purity ≥99.95%, avoids impurity contamination, and ensures high quality of smelting materials.

Long service life: Under suitable conditions, the service life far exceeds that of ordinary metal crucibles, reducing overall costs.

Application Advantages

The High Purity Tantalum Crucible is an essential component in ultra-high temperature and corrosion-resistant industries. Known for its exceptional stability and chemical inertness, this product is widely used in vacuum coating, crystal growth, rare metal smelting, and semiconductor manufacturing.

Key Advantages:

- Outstanding Corrosion Resistance: Performs reliably in strong acids and alkalis, including HCl, H₂SO₄, and HF.

- Ultra-High Melting Point: Withstands temperatures above 3000°C without deformation or contamination.

- Excellent Thermal Conductivity: Ensures even heat distribution during melting and sintering.

- High Purity Stability: With purity levels up to 99.95%–99.99%, it prevents impurity diffusion and ensures product integrity.

- Ideal for Critical Applications: Perfect for aerospace, electronics, and vacuum furnace industries.

The High Purity Tantalum Crucible is especially valued by research institutions and industrial users who require reliable performance in extreme environments.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

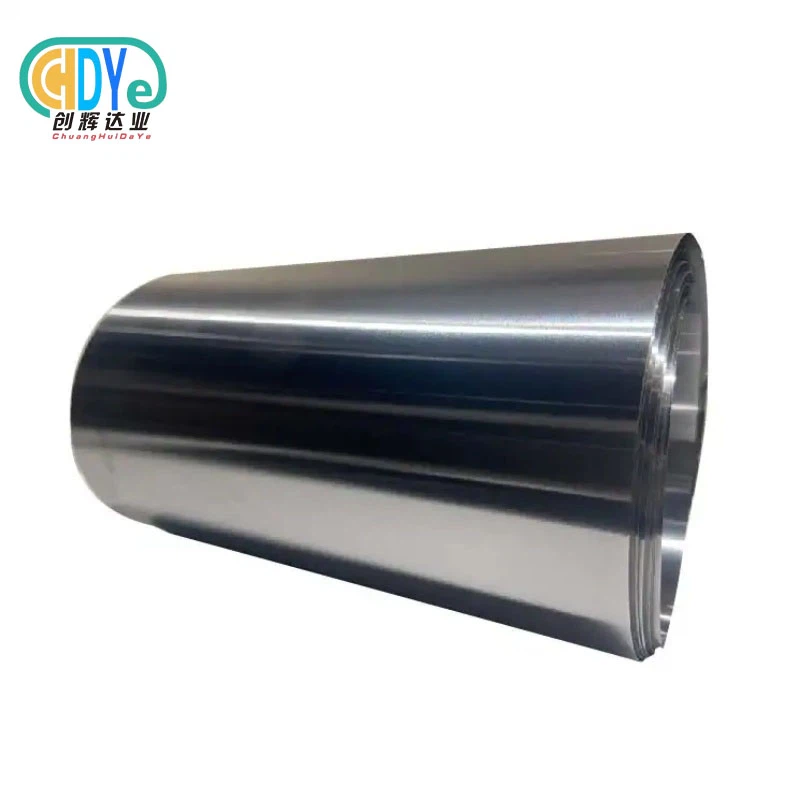

Manufacturing & Process Flow

Our high purity tantalum crucibles are produced through precise metallurgical processes to ensure superior mechanical performance and surface finish.

Typical Process Flow:

- Raw Material Selection: Premium-grade tantalum powder (≥99.95%) is sourced from certified suppliers.

- EB or VAR Melting: Electron Beam or Vacuum Arc Refining ensures high purity and dense structure.

- Hot Forging & Rolling: Homogenization improves strength and grain uniformity.

- Deep Drawing or Spinning: Forming into crucible shapes under controlled temperature and pressure.

- Precision Machining: CNC finishing ensures dimensional accuracy and smooth inner surfaces.

- Annealing & Cleaning: High-vacuum annealing removes internal stress and impurities.

- Inspection & Packaging: 100% quality inspection before shipment.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality is the core of Shaanxi Chuanghui Daye’s production philosophy. Every High Purity Tantalum Crucible undergoes multi-stage testing to ensure chemical stability, microstructure uniformity, and mechanical precision.

Main Quality Tests Include:

- Chemical Composition Analysis (ICP-OES): Confirms tantalum content ≥99.95%.

- Ultrasonic Testing: Detects internal voids and inclusions.

- Microstructure Inspection: Ensures uniform grain size and homogeneity.

- Dimensional Accuracy Check: Precision up to ±0.02 mm.

- Surface Roughness Measurement: Ra ≤ 0.4 μm for high-vacuum use.

All inspection data are documented and provided with a Mill Test Certificate (MTC) upon shipment.

R&D and Customization

With over 30 years of expertise in refractory metal materials, Shaanxi Chuanghui Daye continually develops innovative solutions to meet the evolving needs of high-end industries.

Customization Options:

- Size range: 10 mm–500 mm in diameter, up to 600 mm in height

- Wall thickness: 1–20 mm

- Shapes: Cylindrical, conical, hemispherical, or customized forms

- Coatings: Optional Ta₂O₅ or Mo coating for special purposes

- Surface finish: Mirror polishing or fine machining available

The R&D team works closely with clients to design high-performance High Purity Tantalum Crucibles for unique research or industrial applications.

Packaging & Global Logistics

To ensure product integrity and safety, each High Purity Tantalum Crucible is packaged according to international export standards.

Packaging Details:

- Sealed in vacuum or argon-filled anti-rust film

- Foam-lined shockproof protection

- Packed in export-standard fumigation-free wooden boxes

- Labeled clearly with product specifications and batch numbers

Logistics:

- Air Freight: Fast delivery (DHL, FedEx, UPS) for urgent orders

- Sea Freight: Cost-effective for bulk shipments

- Land Transport: Reliable domestic and regional options

All shipments are insured and fully traceable until they reach the customer’s destination.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye Metal Material Co., Ltd. offers OEM and ODM services to meet specific project requirements across multiple industries.

Our Service Capabilities Include:

- Custom-made crucibles based on drawings or prototypes

- Engineering support for material selection and forming processes

- Pilot-run and small-batch production for R&D needs

- Confidential design and precision machining services

- Comprehensive after-sales support and technical consultation

Our goal is to deliver efficient, cost-effective, and high-quality solutions for every client’s unique needs.

Inspection Process

Each production batch follows a multi-level inspection workflow:

| Stage | Inspection Type | Objective |

|---|---|---|

| Raw Material | Chemical purity test | Verify Ta ≥ 99.95% |

| Forging Stage | Ultrasonic testing | Detect internal defects |

| Machining | Dimensional inspection | Ensure precision fit |

| Surface Treatment | Visual & microcheck | Guarantee smoothness |

| Final Inspection | MTC verification | Confirm compliance to ASTM B708 / GB/T 14841 |

Why Choose Us

1.ISO 9001 certified company

2.100% inspection before shipment and provide Mill test certificate

3.Quick delivery and economical freight cost

4. Prompt reply you can get our reply within 2-5 hours

one-stop solution

professional team

high quality

|

|

|

|

|

|

FAQs

Q1: What purity levels are available for tantalum crucibles?

A1: We offer 99.95% and 99.99% high-purity tantalum crucibles, meeting ASTM B708 and GB/T 14841 standards.

Q2: Can you produce customized crucible sizes and shapes?

A2: Yes, we provide full customization based on drawings or technical requirements.

Q3: What industries typically use your tantalum crucibles?

A3: They are widely used in crystal growth, vacuum coating, rare metal smelting, and semiconductor manufacturing.

Q4: What is your typical lead time?

A4: Standard sizes are available within 7 days; customized orders take 2–3 weeks.

Q5: How do you ensure quality consistency for export orders?

A5: Each batch undergoes 100% inspection and comes with detailed MTC and test reports.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email