- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

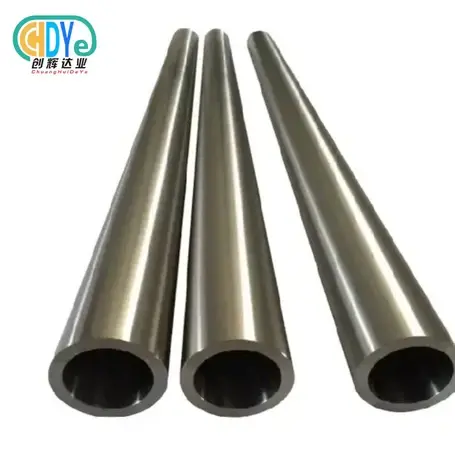

99.95% Pure Molybdenum Tube

Density: 10.2g/cm3

Surface finish: polished/ground

Quality standard: ISO 9001: 2015

Standard:ASTM B 364

Product Introduction

The 99.95% Pure Molybdenum Tube is a high-performance refractory metal product designed for demanding industrial environments where exceptional purity, high temperature resistance, and mechanical strength are essential. Manufactured by Shaanxi Chuanghui Daye Metal Material Co., Ltd., this tube is produced using advanced powder metallurgy and precision machining techniques. The 99.95% purity ensures low impurity levels, excellent thermal conductivity, and outstanding corrosion resistance, making it ideal for applications in electronics, vacuum furnaces, aerospace, and high-temperature heating systems. The 99.95% Pure Molybdenum Tube provides stable and reliable performance under extreme conditions, ensuring long service life and consistent dimensional accuracy for critical industrial uses.

Molybdenum is silver and white metal. Molybdenum is very corrosion resistant and malleable. This metal has a high melting point than other elements. This material is used mainly for strength. Molybdenum metal also gives a beautiful look, and it is an attraction for many applications. Molybdenum is a transport metal; it is quickly forming compounds that easily form compounds with other compounds. Molybdenum tube has the ability to maintain strength at elevated temperatures and the ability to withstand high temperatures, so molybdenum is found in high temperature applications.

Product name: 99.95% Pure molybdenum tube

Purity: ≥99.95%

Density: 10.2g/cm3

Surface finish: polished/ground

Quality standard: ISO 9001: 2015

Standard: ASTM B 364

Specificaion: Outer Diameter (6.5-500) mm * L (10-1500) mm * Thickness (≥ 1mm)

|

Dimensions |

Outer Diameter(mm) |

Wall thickness(mm) |

Length(mm) |

|

<20 |

customized |

≤1500 |

|

|

30-50 |

2-10 |

||

|

50-200 |

3-15 |

||

|

200-500 |

>4 |

||

|

>500 |

customized |

Our Advantage

1. We are a manufacturer with more than 10 years of production and export experience.

2. Various stock size and can provide quick delivery

3. Competitive products price with good quality

Our main products

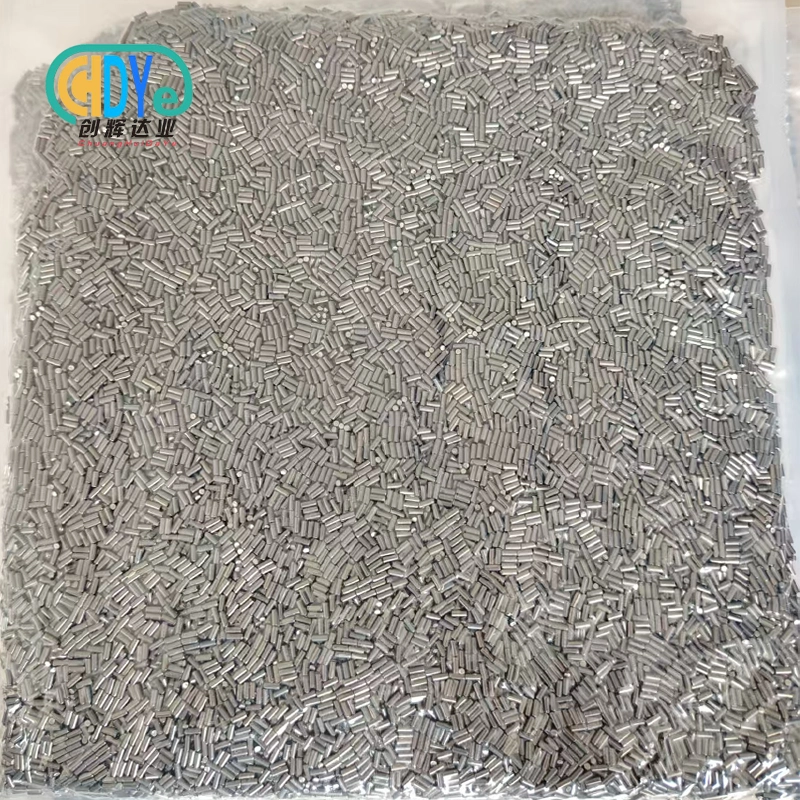

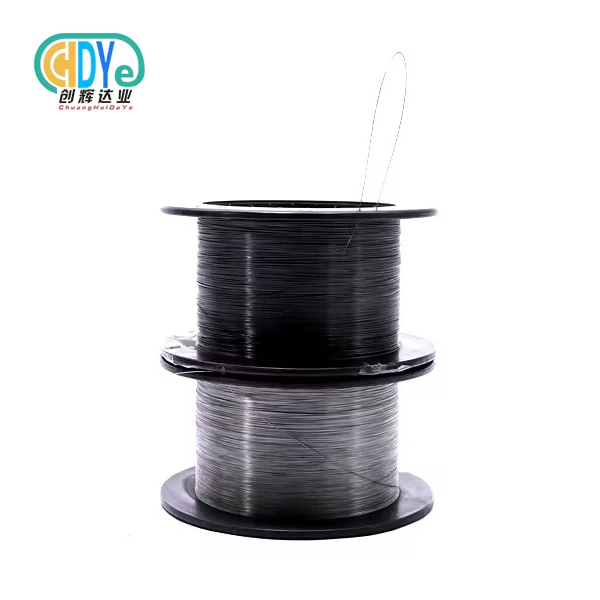

Molybdenum products: plates, rods/electrode, crucible, tube, boat, fasteners, various molybdenum workpieces, etc.

2) Tungsten products: plate, bars, crucible, tube, wire, boat, fasteners, etc.

3) Titanium & tantalum niobium products: plate, bars, wire, tube crucible,etc.

Application Advantages

Molybdenum tube is mainly used in vacuum coating, solar energy, thermocouple protection pipe in high temperature furnace, sapphire single crystal furnace, high temperature sintering furnace support parts, etc.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Our advanced production line ensures high quality and dimensional precision at every step:

- Raw material preparation: High-purity molybdenum powder (≥99.95%) is carefully selected and analyzed.

- Pressing and sintering: Powder is pressed into billets and sintered at high temperature to achieve high density.

- Extrusion and forging: The sintered billet is extruded into tube form with excellent uniformity and grain structure.

- Machining and polishing: Precision CNC machining guarantees accurate inner and outer diameters with smooth finishes.

- Annealing and cleaning: Heat treatment enhances ductility and removes surface oxides.

- Final inspection: Each tube undergoes detailed dimensional and purity verification before packaging.

This systematic process ensures the 99.95% Pure Molybdenum Tube meets the highest international quality standards.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality is central to our manufacturing philosophy. Each production stage is controlled under ISO 9001:2015 standards.

- Chemical composition testing: Spectrographic analysis ensures purity ≥99.95%.

- Mechanical testing: Tensile strength, hardness, and elongation tests guarantee structural reliability.

- Dimensional inspection: Each tube is checked for straightness, roundness, and surface finish.

- High-temperature testing: Simulated performance under operational temperatures to ensure stability.

- Visual inspection: Detects any surface imperfections or contamination.

These strict measures ensure that every 99.95% Pure Molybdenum Tube leaving our factory meets or exceeds customer expectations.

R&D and Customization

With a strong research and development team, Shaanxi Chuanghui Daye offers customized molybdenum solutions for advanced applications.

- Tailored specifications: Inner/outer diameters, wall thickness, and lengths available upon request.

- Material optimization: Alloying and refining processes enhance performance for specialized uses.

- Prototype and small-batch development: Designed for R&D and pilot production needs.

- Surface treatment and coating: Optional polishing or protective coatings improve oxidation resistance.

Our innovation-driven approach allows us to continuously improve the structural and functional performance of molybdenum tubes for global industries.

Packaging & Global Logistics

We ensure safe and professional handling for every shipment:

- Packaging: Anti-rust film, foam wrapping, and vacuum sealing for protection.

- Outer box: Export-grade wooden crates designed to prevent damage during transportation.

- Labeling: Each package clearly marked with product details and batch number for traceability.

- Logistics: Reliable global transport via air, sea, or courier to over 50 countries.

Our efficient logistics network ensures the 99.95% Pure Molybdenum Tube arrives in perfect condition and on time, ready for immediate use.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye Metal Material Co., Ltd. offers professional OEM and ODM services tailored to your project requirements.

- Customized dimensions and tolerances according to drawings and industrial needs.

- Material consultation and design support for specific environments or functions.

- Prototype production for performance validation.

- Technical assistance and after-sales service for long-term cooperation.

We deliver competitive prices, reliable quality, and timely delivery to ensure a smooth experience for global partners.

Inspection Process

- Incoming material inspection: Verify purity, density, and chemical composition of molybdenum powder.

- Process monitoring: Continuous checks during pressing, sintering, and machining stages.

- Size and tolerance measurement: Using precision instruments to ensure dimensional accuracy.

- Surface and defect detection: Employing ultrasonic and visual tests to identify flaws.

- Final quality review: Conducted by senior inspectors before packaging and shipment.

This comprehensive inspection process guarantees consistent performance and full traceability for every tube produced.

Why Choose Us

- Over 30 years of expertise in rare metal production

- ISO 9001:2015 certified manufacturing system

- Advanced equipment for melting, forging, and machining

- Global exports to 50+ countries

- Fast delivery within 7 days for standard sizes

Partnering with Shaanxi Chuanghui Daye means choosing reliability, technical precision, and long-term value in refractory metal manufacturing.

|

|

|

|

|

|

FAQs

Q1: What is the purity level of your molybdenum tubes?

A1: All our tubes are made from molybdenum with a minimum purity of 99.95%, ensuring superior high-temperature performance.

Q2: Can you supply customized sizes?

A2: Yes, we offer complete OEM customization based on your drawings and technical requirements.

Q3: What industries commonly use molybdenum tubes?

A3: They are widely used in semiconductor, aerospace, vacuum furnace, and metallurgical applications.

Q4: How do you ensure quality consistency?

A4: Every tube undergoes strict inspection and testing throughout the production process in accordance with ISO 9001 standards.

Q5: What is your standard delivery time?

A5: Regular specifications are available within 7 days, while customized orders depend on specific requirements.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email