- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Product Introduction

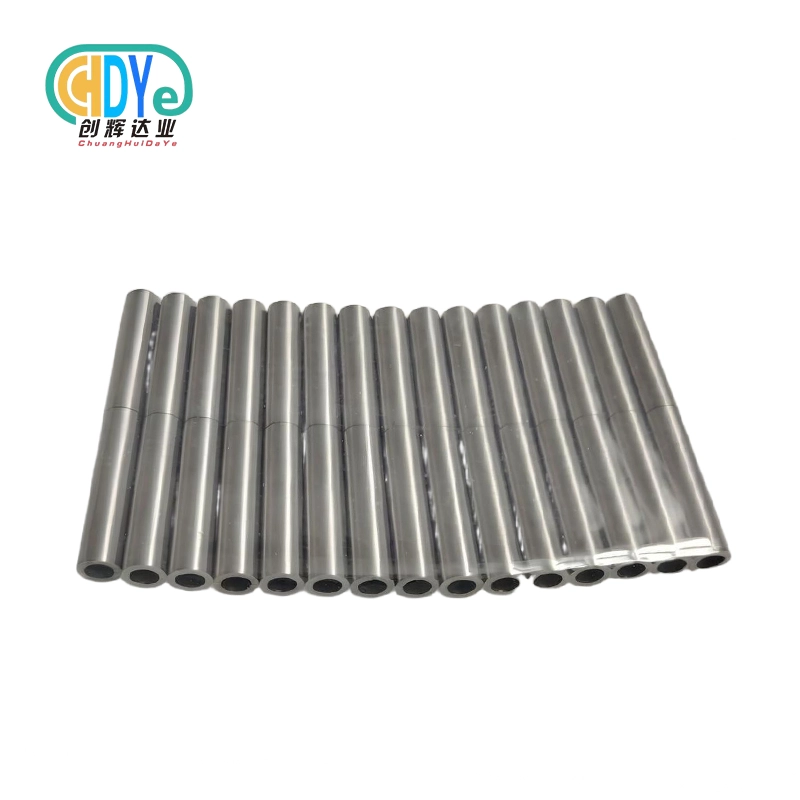

The Molybdenum Pipe For Sale offered by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a high-performance tubular product designed for superior strength, thermal stability, and corrosion resistance under extreme conditions. Manufactured using ultra-high-purity molybdenum materials and advanced powder metallurgy techniques, our pipes exhibit excellent mechanical properties, uniform grain structure, and reliable dimensional precision.

Molybdenum, known for its exceptional melting point of around 2620°C, delivers outstanding performance in high-temperature and corrosive environments. These pipes are ideal for applications where ordinary metals fail, including vacuum furnaces, semiconductor fabrication, aerospace systems, and chemical equipment. With more than 30 years of manufacturing experience, our company ensures every product meets international standards such as ASTM B387 and GB/T 4182.

Molybdenum pipe are made of high-purity molybdenum material and have excellent high-temperature performance, corrosion resistance, and mechanical properties. Due to its excellent characteristics, molybdenum pipes are widely used in various fields such as high-temperature vacuum equipment, aerospace, and chemical industries.

· Standard:ASTM B387

· Material:Mo, MoLa, TZM

· Specifications:OD(φ6-φ200mm) x Thickness(1-40mm) x Length(100-1500mm)

· Delivery Time:10~15 days

Certification: ISO9001:2015

· Payment Method:T/T, PayPal, etc

Application

1. Medical equipment: In the medical industry, molybdenum pipes are commonly used as target materials for X-ray tubes, as well as in medical imaging systems, radiation therapy equipment, and other diagnostic and therapeutic devices. Its high temperature stability and energy conversion characteristics make it advantageous in these applications.

2. Thermocouple protection tube: Molybdenum pipe is an ideal material for measuring high temperature environments and is commonly used in the manufacture of thermocouple protection tubes.

3. High temperature furnace components: Molybdenum pipes play an important role in manufacturing heating elements and supporting structures for various high-temperature furnaces, and can withstand high temperature environments without being easily oxidized or eroded.

4. Electronic devices: Molybdenum tubes are used to manufacture electronic devices, such as X-ray tubes, microwave tubes, etc., as the gate of electronic tubes. In addition, molybdenum pipes are also used as heating elements in semiconductor material production equipment.

5. Lighting: In the field of lighting, molybdenum pipes are used to manufacture filaments for halogen lamps, high-temperature furnace lamps, etc.

6. Electrode material: Molybdenum pipes are also used as electrode materials for electroplating, resistance welding, and other applications.

7. Chemical industry: Molybdenum pipes are used as reaction vessels and catalyst carriers in the chemical industry, and can work stably under high temperature and high pressure conditions. They are suitable for equipment such as reactors, heat exchangers, and catalyst carriers.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Our Molybdenum Pipe For Sale is produced through a carefully controlled process to ensure purity, consistency, and structural integrity:

- Powder Preparation: Selection of high-purity molybdenum powder (≥99.95%) with controlled particle size and low oxygen content.

- Isostatic Pressing: Uniform compaction under high pressure to create dense and defect-free billets.

- Vacuum Sintering: High-temperature sintering in a vacuum furnace to achieve a homogeneous microstructure.

- Hot Working: Extrusion and rotary swaging refine grain size, enhance strength, and improve surface uniformity.

- Machining & Finishing: CNC precision machining ensures exact dimensions, smooth internal surfaces, and accurate tolerances.

- Cleaning & Inspection: Each pipe undergoes thorough ultrasonic, dimensional, and surface inspections before packaging.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality assurance is at the heart of Shaanxi Chuanghui Daye’s operations. All stages of production are subject to rigorous testing and documentation, including:

- Raw Material Testing: Chemical composition analysis to confirm molybdenum purity and absence of impurities.

- Process Monitoring: Continuous temperature, pressure, and density control during sintering and forming.

- Mechanical Testing: Tensile strength, hardness, and elongation tests performed per ASTM standards.

- Non-Destructive Examination: Ultrasonic and eddy current testing to detect internal or surface defects.

- Dimensional Verification: Precision measurements ensure compliance with specified tolerances.

- Final Surface Inspection: Polished or ground finishes verified for smoothness and appearance.

R&D and Customization

Backed by a strong R&D team and decades of rare metal expertise, we continuously develop new molybdenum-based materials and production technologies. Our customization capabilities include:

- Custom Dimensions: Outer diameter, wall thickness, and length tailored to customer requirements.

- Alloy Modifications: Options for TZM and Mo-La alloys for improved mechanical or oxidation resistance.

- Surface Treatments: Machined, ground, polished, or chemical cleaned finishes available.

- Application-Specific Design: Engineering support for specialized high-temperature or high-pressure uses.

Innovation and flexibility enable us to deliver solutions that meet the precise needs of customers in aerospace, semiconductor, and energy sectors.

Packaging & Global Logistics

Every Molybdenum Pipe For Sale is packaged to meet international shipping standards, ensuring safe delivery worldwide:

- Packaging: Vacuum-sealed or anti-rust film wrapping, protected by foam layers, and packed in solid export-grade wooden crates.

- Marking: Each package clearly labeled with product specifications, material grade, and batch number.

- Logistics: Reliable air, sea, and express delivery options with full tracking capability.

- Storage Recommendations: Store in a dry, ventilated environment to prevent oxidation.

With strong cooperation from global logistics partners, we guarantee fast and secure delivery to over 50 countries, including the United States, Germany, Japan, South Korea, and France.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

We provide comprehensive OEM and ODM services to support clients across industries:

- Prototype and small-batch production

- Design-to-manufacture support based on CAD or 3D drawings

- Material and process consulting for specific industrial requirements

- Custom branding and private labeling options

- Technical documentation and certification support

Our engineering and production teams work closely with customers to develop tailored solutions that enhance performance and reduce operational costs.

Inspection Process

Each molybdenum pipe passes through a multi-stage inspection workflow:

- Material Verification: Confirmation of batch composition and purity.

- Dimensional Measurement: Length, diameter, and wall thickness checked using precision instruments.

- Visual & Surface Check: Inspection for scratches, cracks, or contamination.

- Ultrasonic Testing: Non-destructive detection of internal inclusions or porosity.

- Mechanical Property Testing: Tensile and hardness tests validate performance consistency.

- Final Review: Approved only after meeting all quality and specification requirements.

Why Choose Us

- Over 30 years of experience in non-ferrous and refractory metal production.

- ISO 9001:2015 certified quality management system.

- Advanced equipment including electron beam furnaces, annealing furnaces, and CNC lathes.

- Fast delivery—typically within 7 working days for standard sizes.

- Strong R&D capability with professional technical support.

- Global reputation for quality, reliability, and customer satisfaction.

At Shaanxi Chuanghui Daye, we combine expertise, innovation, and service excellence to deliver world-class molybdenum products that exceed expectations.

|

|

|

|

|

|

FAQs

Q1: What are the advantages of molybdenum pipes over stainless steel?

A1: Molybdenum pipes maintain structural stability and corrosion resistance at temperatures where stainless steel deforms, making them ideal for high-heat and vacuum applications.

Q2: Can you produce customized dimensions or alloys?

A2: Yes, we offer full customization of size, wall thickness, and material composition based on project requirements.

Q3: How do you ensure quality during production?

A3: Every process—from raw material selection to final inspection—is strictly controlled under ISO 9001:2015 standards.

Q4: What is the typical delivery time?

A4: Standard specifications are usually shipped within 7 days, while custom orders depend on quantity and complexity.

Q5: Do you provide third-party testing reports?

A5: Yes, we can arrange SGS, TUV, or other independent inspections upon customer request.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email