- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

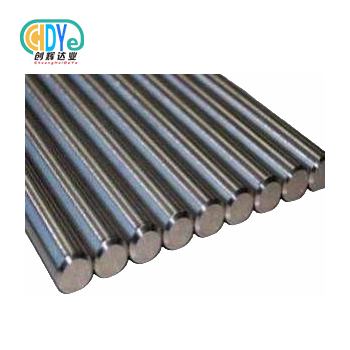

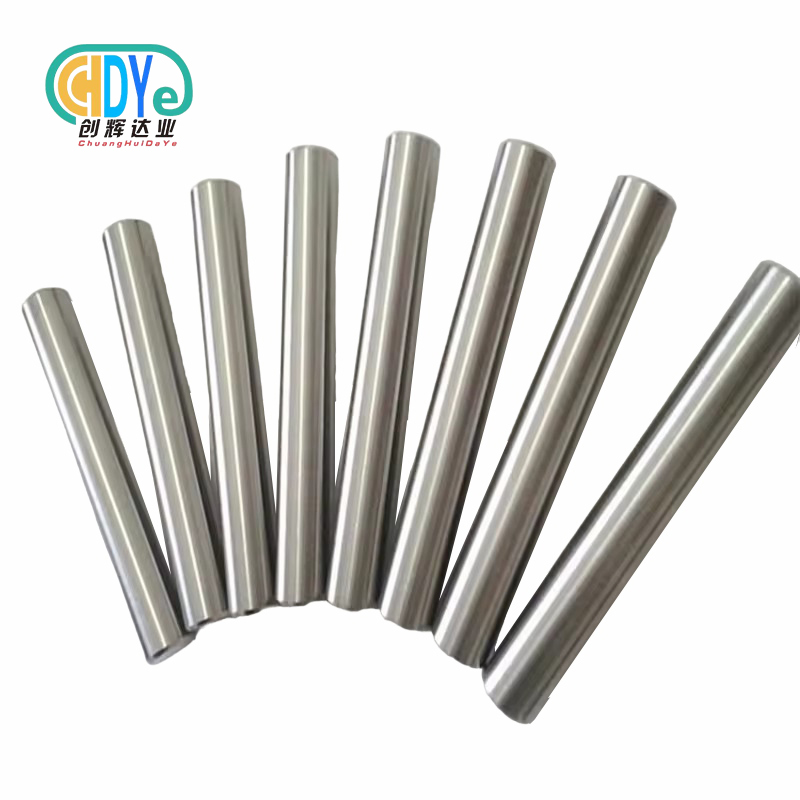

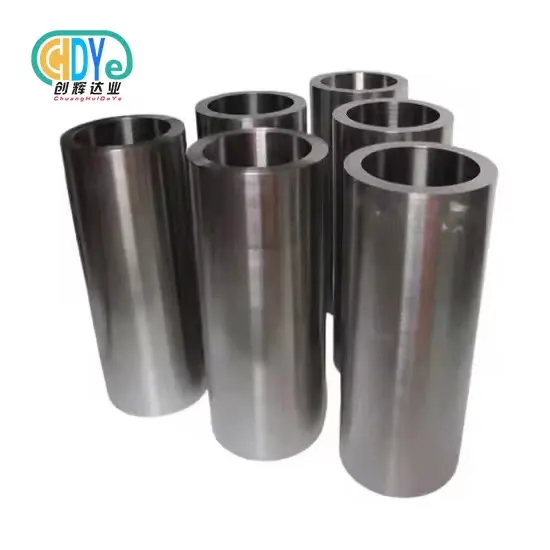

Molybdenum Seamless Tube

Outer diameter Φ(1.0~50)mm× wall thickness (0.5~5)mm×Length (50~1000)mm

Product Introduction

The Molybdenum Seamless Tube supplied by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a high-performance product designed for extreme environments that demand exceptional thermal stability and corrosion resistance. Made from high-purity molybdenum, this seamless tubing demonstrates superior mechanical strength, dimensional precision, and chemical inertness. It is ideal for use in high-temperature furnaces, electronic components, vacuum systems, and aerospace applications.

With over 30 years of expertise in the rare metal industry, Chuanghui Daye manufactures every Molybdenum Seamless Tube using advanced melting, rolling, and machining techniques under strict ISO 9001:2015 quality control standards. The material’s purity and microstructure ensure consistent performance, minimal contamination, and long service life even in highly corrosive or high-vacuum environments.

The product is available in a variety of diameters, wall thicknesses, and lengths, with both standard and custom specifications according to ASTM, GB, and ISO standards. This makes it a preferred choice for industrial users seeking reliable and precision-engineered molybdenum tubing solutions.

Molybdenum seamless tube shall be made by any seamless method that will yield a product meeting the requirements of this specification.

Specification: Outer diameter Φ(1.0~50)mm× wall thickness (0.5~5)mm×Length (50~1000)mm

Main characteristics

1. Easy to process.

2. High intensity. Molybdenum and molybdenum alloys have high strength.

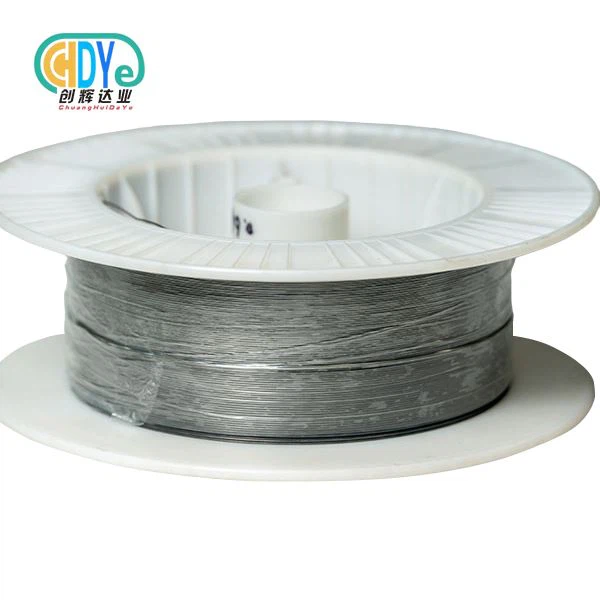

3. Good electrical and thermal conductivity. Molybdenum is second only to silver, copper and gold in conducting electricity and heat.

4. Good corrosion resistance. The surface of molybdenum is easy to naturally produce a layer of dense and firm protective film, which can well protect the matrix from corrosion.

Packaging & Shipping

Packing: Inner packing is moisture proof paper and thicker foam

Outer packing is exporting wooden box

Our Shipment Methods:

By express EMS,TNT,DHL,UPS,FedEx

By Sea or Air transportation

We also can deliver as the customers' need,send the material to the port.

Application Advantages

molybdenum tube is mainly used in thermocouple protection tube in high temperature furnace, sapphire single crystal furnace, support parts in high temperature sintering furnace, etc.

Advantages: It has the advantages of high dimensional accuracy, high internal and external surface finish, good straightness, and no deformation under high temperature strength.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Sintered molybdenum tube:

Isostatic pressing----medium frequency sintering----machining----finished tungsten tube

Drilled molybdenum tube: finished molybdenum rod----drilling----wire cutting

Production equipment: isostatic pressing, medium frequency sintering furnace, CNC lathe, CNC drilling and milling machine, coreless grinder, wire cutting machine

|

|

|

|

|

|

|

|

Quality Control & Inspection

At Shaanxi Chuanghui Daye, quality is our top priority. Our ISO 9001:2015-certified system ensures that every production step is carefully monitored. Key inspection procedures include:

- Chemical Composition Analysis: Conducted via spectrometer testing to verify molybdenum purity.

- Ultrasonic and Eddy Current Testing: To detect internal flaws and ensure full density.

- Dimensional Accuracy Check: Using precision measuring instruments.

- Surface and Visual Inspection: To confirm the absence of cracks, scratches, and oxidation.

- Mechanical Property Testing: To verify tensile strength, elongation, and hardness.

Only products meeting all quality standards are approved for shipment to ensure consistent reliability and performance.

R&D and Customization

Our experienced R&D team continuously explores new applications for molybdenum materials in emerging industries. We can provide:

- Customized grades and purity levels based on customer requirements.

- Specific tube dimensions and tolerances.

- Advanced surface treatments for enhanced corrosion resistance.

- Joint R&D projects for unique material solutions.

Through close technical cooperation, we deliver tailor-made Molybdenum Seamless Tube products optimized for the client’s production process and performance needs.

Packaging & Global Logistics

Each product is packaged according to international export standards to ensure safety during transportation:

- Packaging: Vacuum-sealed or anti-rust film with foam protection.

- Outer Boxes: Strong export-grade wooden crates to prevent mechanical damage.

- Labeling: Each package includes product name, grade, size, heat number, and batch code.

With reliable air, sea, and land logistics, we guarantee on-time global delivery to over 50 countries and regions, including the United States, Germany, Japan, South Korea, and Singapore.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye Metal Material Co., Ltd. offers comprehensive OEM and ODM services for global clients:

- Custom specifications and tolerances.

- Small-batch and prototype production.

- Technical consulting and design optimization.

- Consistent supply and flexible order management.

Our professional engineering support team ensures that every Molybdenum Seamless Tube is tailored to meet the highest performance requirements of different industries.

Inspection Process

Before shipment, every batch undergoes a multi-stage inspection protocol:

- Material Verification – Checking the purity and lot traceability.

- Dimensional Inspection – Ensuring accuracy of inner/outer diameters and wall thickness.

- Nondestructive Testing – Ultrasonic and eddy current testing for internal flaws.

- Surface Cleaning and Passivation – Removal of oxidation residues and contaminants.

- Final Packaging Inspection – Verifying labeling, sealing, and documentation.

These procedures guarantee that all products meet international export and performance standards.

Why Choose Us

- 30+ Years of Expertise in rare metal manufacturing.

- ISO 9001:2015 Certified production and inspection system.

- Comprehensive Material Range covering titanium, molybdenum, tungsten, niobium, and tantalum.

- Fast Delivery: Standard lead time within 7 days.

- Global Market Presence: Supplying over 50 countries worldwide.

- Custom Engineering Solutions: Designed to meet your specific project needs.

Choosing Chuanghui Daye means choosing a reliable partner for advanced refractory and rare metal solutions.

|

|

|

|

|

|

FAQs

Q1: What sizes and tolerances are available?

A: We provide tubes with diameters ranging from 3 mm to 120 mm, customized according to customer drawings and tolerance requirements.

Q2: What purity levels do you offer?

A: Standard molybdenum purity is ≥99.95%, with higher purities available upon request.

Q3: Can the product be used in high vacuum environments?

A: Yes, the Molybdenum Seamless Tube is suitable for ultra-high-vacuum systems due to its low vapor pressure and high thermal resistance.

Q4: How do you ensure consistent quality?

A: Each production stage undergoes strict inspection and documentation, supported by ISO 9001:2015 certification.

Q5: Do you offer OEM or customized production?

A: Absolutely. We provide full OEM and ODM services to meet your specific design, application, and performance requirements.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email