- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

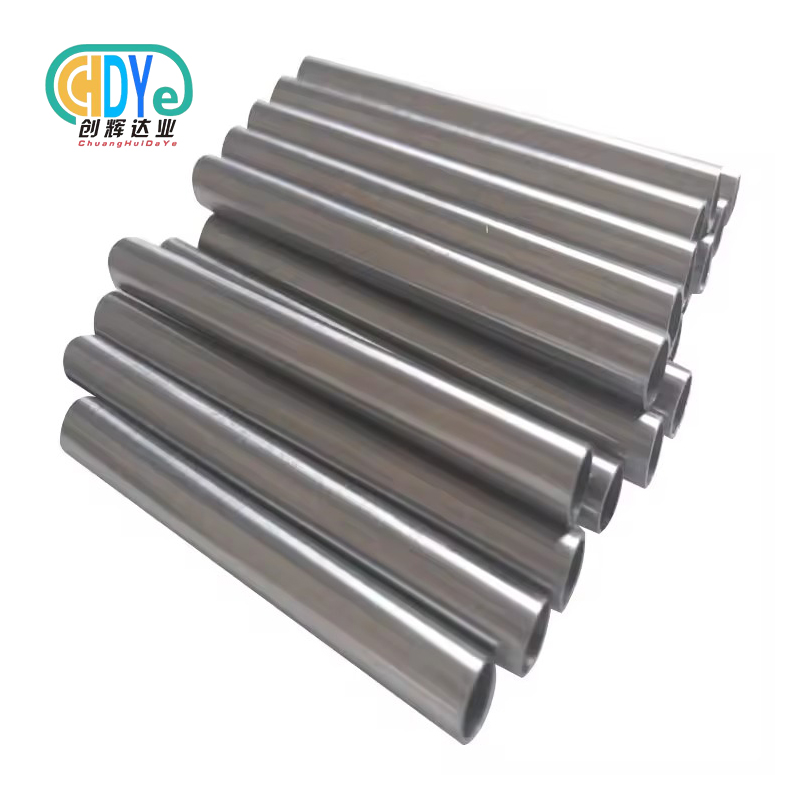

tantalum rods

2. Diameter: 2–100 mm

3. Density: 16.65 g/cm³

>4. Applications: Chemical, electronics

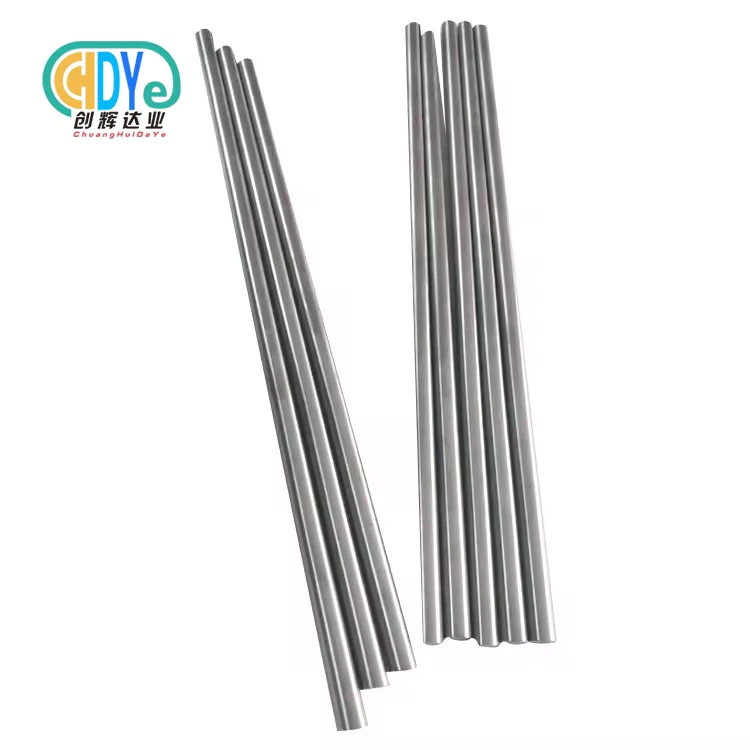

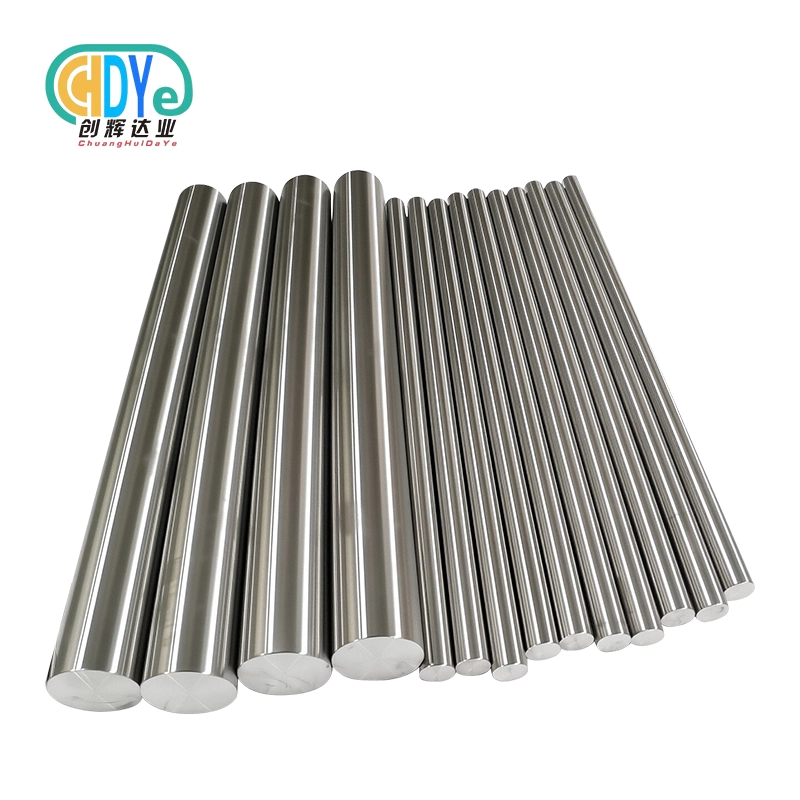

Welcome to your trusted source for premium tantalum rods. Whether you need corrosion-resistant materials for chemical processing or biocompatible components for medical devices, our tantalum rods deliver exceptional performance in the most demanding environments. With over 30 years of experience in rare metal manufacturing, we provide superior quality products that meet your exact specifications. Our rods feature purity levels exceeding 99.9% and are manufactured using advanced cold working processes to ensure optimal mechanical properties.

Key Features and Benefits

Our tantalum products offer unmatched corrosion resistance, making them ideal for aggressive chemical environments. You'll appreciate their excellent biocompatibility for medical applications and superior thermal stability for high-temperature operations. The naturally occurring oxide film provides exceptional protection against most acids and organic compounds.

Key advantages include:

- Outstanding corrosion resistance in harsh chemicals

- Excellent biocompatibility for medical implants

- High-temperature stability up to 3000°C

- Superior mechanical strength and durability

- Exceptional electrical conductivity properties

Technical Specifications

|

Product name |

Tantalum rods |

|

Application |

Electronic Light Source Part;Implantation Parts.etc |

|

Purity |

99.95% Min |

|

Density |

16.65g/cm3 |

|

Surface |

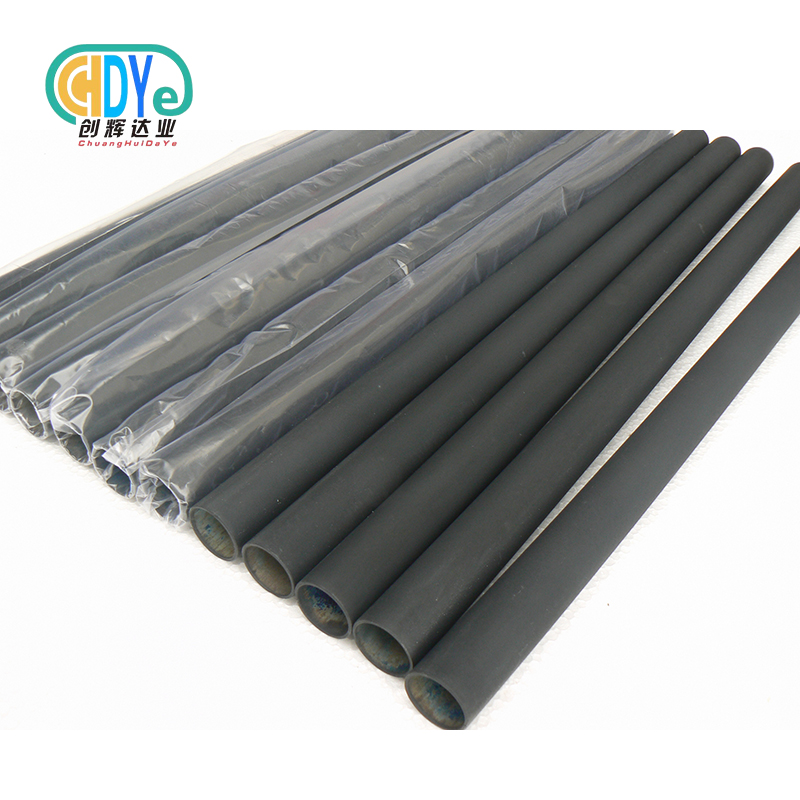

Polished and Black |

|

Size |

Φ2.0—100mm*L,customized |

|

Chemical Composition |

Pure Tantalum Rods/Bars |

|

Melting point |

3400℃ |

|

Packing |

Wooden box |

|

Production process |

Tantalum raw material - electron beam vacuum melting - forging - polishing - inspection - delivery |

|

Grade |

Chemical Composition (≤%) |

||||||||||||

|

Ta |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Nb |

O |

C |

H |

N |

||

|

Ta1 |

Bal. |

0.005 |

0.005 |

0.002 |

0.01 |

0.01 |

0.002 |

0.03 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

|

Ta2 |

Bal. |

0.03 |

0.02 |

0.005 |

0.04 |

0.03 |

0.005 |

0.1 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

|

TaNb3 |

Bal. |

0.03 |

0.03 |

0.005 |

0.04 |

0.03 |

0.005 |

<3.5 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

|

TaNb20 |

Bal. |

0.03 |

0.03 |

0.005 |

0.04 |

0.03 |

0.005 |

17.0-23.0 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

|

Ta2.5W |

Bal. |

0.005 |

0.005 |

0.002 |

3.0 |

0.01 |

0.002 |

0.04 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

|

Ta10W |

Bal. |

0.005 |

0.005 |

0.002 |

11 |

0.01 |

0.002 |

0.04 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

Available Grades and Materials

We offer various grades to meet your specific requirements. Our standard grade provides excellent general-purpose performance, while our high-purity grade delivers enhanced properties for critical applications. All materials comply with international standards and undergo rigorous quality testing.

Manufacturing Process

Our rods are manufactured through precision cold working processes starting from high-purity ingots. We employ forging, rolling, swaging, and drawing techniques either individually or in combination to achieve your desired dimensions. This controlled manufacturing ensures consistent mechanical properties and surface finish throughout each rod.

|

|

|

|

|

|

|

|

Applications and Industries

Tantalum rods serve diverse industries including:

Chemical Processing: Heat exchangers, reaction vessels, and piping systems

Electronics: Capacitor components and semiconductor applications

Medical: Surgical implants and prosthetic devices

Aerospace: High-temperature structural components

Oil & Gas: Corrosion-resistant equipment in harsh environments

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain strict dimensional tolerances to ensure your components fit perfectly. Standard diameter tolerances are ±0.05mm for rods under 10mm and ±0.1mm for larger diameters. Length tolerances are typically ±1mm. Custom tolerances are available upon request.

Product Features in Detail

The exceptional corrosion resistance stems from tantalum's natural oxide layer formation. This protective film remains stable in most acids, including sulfuric and hydrochloric acid. Your applications will benefit from this metal's inertness to practically all organic and inorganic compounds.

The biocompatibility makes these materials perfect for medical implants. Body fluids don't affect the material properties, ensuring long-term reliability in biological environments.

Quality Assurance and Testing

Every rod undergoes comprehensive testing including chemical composition analysis, mechanical property verification, and dimensional inspection. We maintain complete traceability documentation for each batch. Our quality management system ensures consistent product performance.

|

|

|

OEM & Customization Services

We specialize in custom manufacturing to meet your unique requirements. Whether you need specific dimensions, surface finishes, or material grades, our experienced team works closely with you to develop the perfect solution. We accommodate both prototype quantities and large-scale production runs.

Packaging and Shipping

Your rods are carefully packaged in protective materials to prevent damage during transit. We use moisture-resistant packaging and appropriate cushioning materials. Our logistics team coordinates worldwide shipping to ensure timely delivery to your facility.

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us

Located in China's "Titanium Capital," we leverage over three decades of rare metal expertise to serve customers across 50+ countries. Our founder's extensive industry experience ensures you receive knowledgeable support and reliable products. We're committed to competitive pricing, on-time delivery, and exceptional customer service.

Our focus on continuous improvement and customer satisfaction has established long-term partnerships worldwide. You can trust our reliability, honesty, and technical expertise for your critical applications.

|

|

|

|

|

|

FAQs

Q: What's the minimum order quantity?

A: We accommodate orders from single pieces to large production quantities.

Q: Can you provide material certificates?

A: Yes, we provide complete chemical and mechanical property certificates with each shipment.

Q: What's the typical lead time?

A: Standard products ship within 10days. Custom specifications may require additional time.

Q: Do you offer technical support?

A: Our experienced team provides comprehensive technical assistance for material selection and application guidance.

Contact Us

Ready to discuss your tantalum rod requirements? Our technical team is here to help you select the perfect material for your application. Contact us today at info@chdymetal.com for detailed quotations, technical specifications, or any questions about our products and services.

Learn about our latest products and discounts through SMS or email