- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

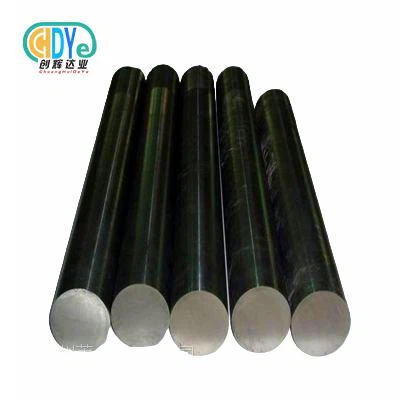

Medical Titanium Bar

2. Grade :Gr1 Gr2 Gr5 Gr5ELI

3. Diameter: 4mm – 20mm

4. Length: 2500- 3000mm

5. Tolerance: h7, h8, h9

Product Details

Medical Titanium Bar is a high-purity titanium product specifically engineered for advanced biomedical use, including orthopedic fixation, medical implants, and surgical instruments. It offers outstanding biocompatibility, corrosion resistance, and a superior strength-to-weight ratio, making it an ideal choice for long-term integration within the human body. Manufactured in strict accordance with ASTM F136 (Ti-6Al-4V ELI), ASTM F67 (Pure Titanium for Surgical Implant Applications), and ISO 5832-3 standards, each bar ensures exceptional surface quality, mechanical uniformity, and full traceability throughout production.

Medical titanium bar materials play a vital role in modern healthcare engineering. In orthopedic prosthetics, they are used to create high-performance joint replacements designed to replicate natural bone structure with precision. For dental applications, titanium rods form the foundation of implant abutments, offering exceptional osseointegration and long-term stability without the need for replacement. In surgical instrumentation, these bars enable the manufacture of seamless, contamination-free tools essential for precision procedures such as endoscopic and microscopic surgeries.

Specification

1.Standard: ASTM F67,ASTM F136

2. Grade :Gr1 Gr2 Gr5 Gr5ELI

3. Diameter: 4mm – 20mm

4. Length: 2500- 3000mm

5. Tolerance: h7, h8, h9

|

item |

Medical titanium bar |

|

Model Number |

Gr5,Gr5 ELI |

|

Application |

Medical |

|

Length |

50-6000mm |

|

Grade |

Titanium Alloy |

|

weight |

Actual Weight |

|

Standard |

ASTM F67, ASTM F136 |

|

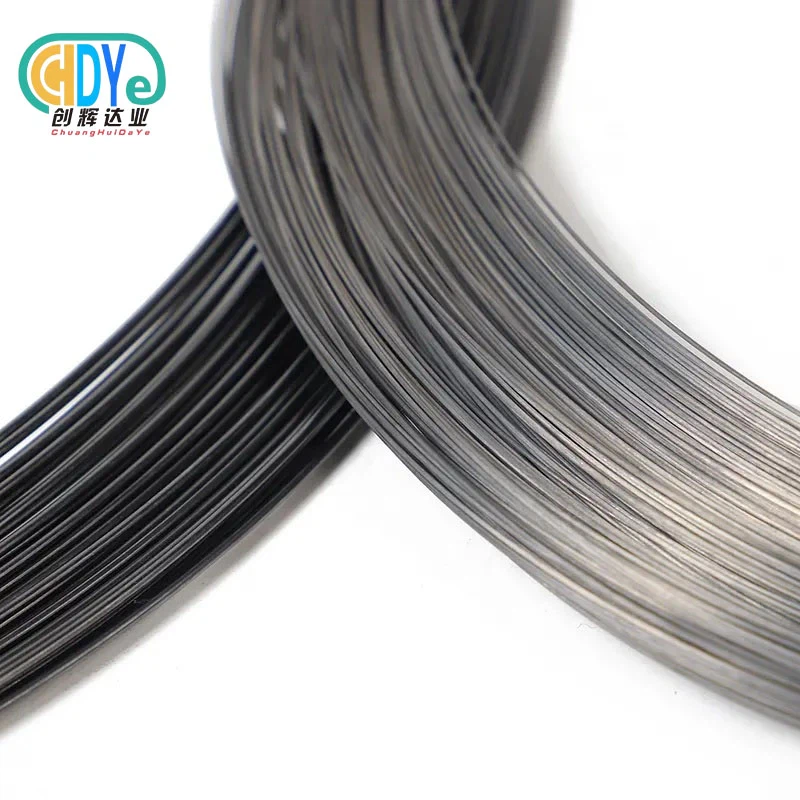

Surface |

Polished Surface,Black, acid pickling |

|

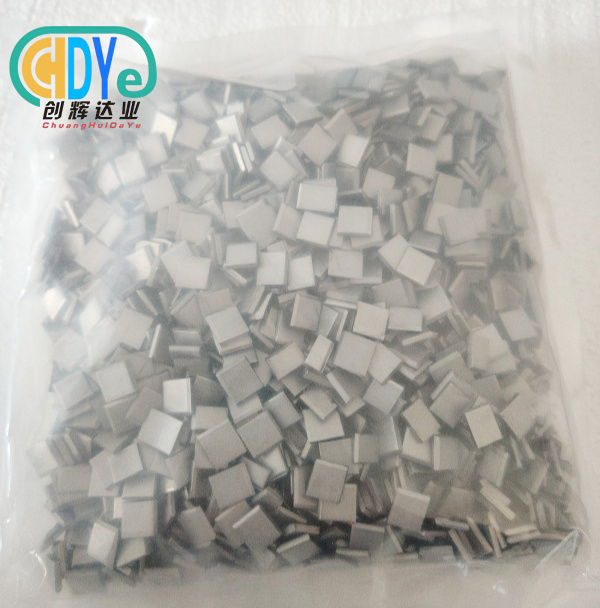

MOQ |

1 Piece we support sample order |

|

Condition |

Cold (Hot) Rolled Annealed |

|

Other available titanium grade |

Gr1 Gr.2 Gr5, Gr7,GR9,GR12,Gr23 |

|

Certificates |

ISO9001:2008 |

|

Payment term |

30% T/T in advance,70% balance before shipment |

Inspection Process

1.Appearance and dimension inspection to ensure every titanium rod meets tolerances.

2. Ultrasonic and eddy current testing make sure the product without cracks and scratch

3.The infra-red detector ensure the whole bar's roundness consistency

4. Testing Tensile strength, yield strength by our Tension Tester and the Third party lab to double check the quality.

Manufacturing & Processing Capability

Our production facility is equipped with advanced melting, forging, rolling, and precision machining lines dedicated to titanium and titanium alloy medical materials.

- Melting Process: Vacuum arc remelting (VAR) and electron beam melting (EBM) to ensure high purity and homogeneity.

- Forming: Hot forging, rotary swaging, and precision rolling to achieve uniform grain structure.

- Heat Treatment: Controlled annealing for optimized mechanical and fatigue properties.

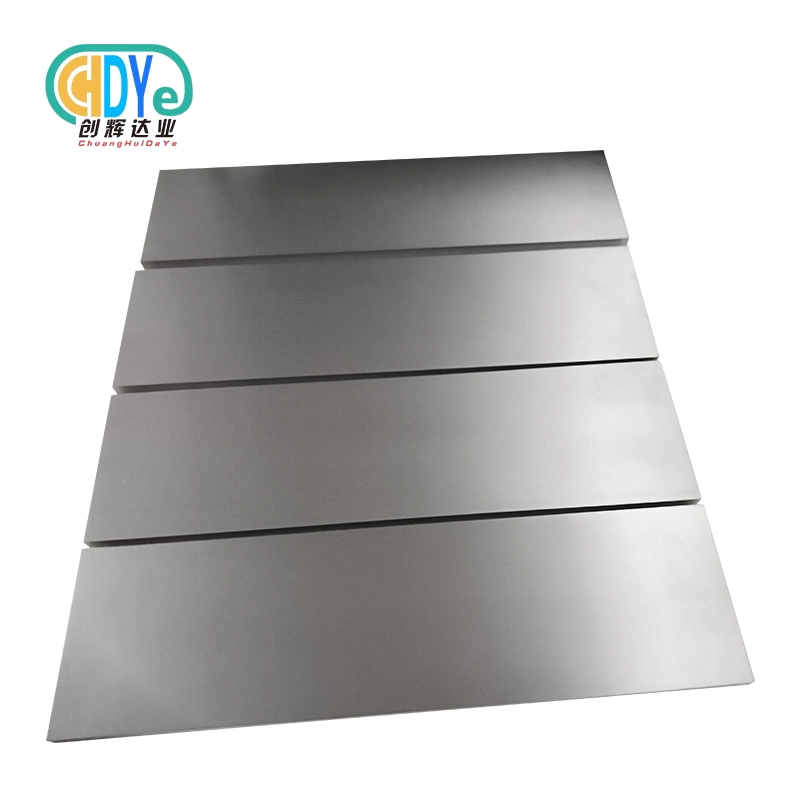

- Machining: Centerless grinding, straightening, and polishing to achieve tight dimensional tolerance (±0.01 mm).

Customized dimensions and alloy compositions can be provided for orthopedic, dental, and cardiovascular applications.

|

|

|

|

|

|

|

|

Surface & Mechanical Performance

All Medical Titanium Bars undergo rigorous surface finishing and mechanical property testing to meet medical-grade requirements.

Surface Finish: Polished, pickled, or mirror finish (< Ra 0.2 μm)

Mechanical Properties:

- Tensile Strength: ≥ 860 MPa (Gr5 ELI)

- Yield Strength: ≥ 795 MPa

- Elongation: ≥ 10%

- Reduction of Area: ≥ 25%

- Density: 4.43 g/cm³

Corrosion Resistance: Excellent resistance to body fluids, saline, and sterilization processes.

Biocompatibility: Proven tissue compatibility without cytotoxicity or allergic response.

Quality Assurance

Each Medical Titanium Bar is manufactured under a strict quality management system certified by ISO 13485 and ISO 9001.

Comprehensive inspection procedures include:

- 100% ultrasonic testing for internal defects

- Chemical composition analysis using ICP-OES

- Mechanical testing (tensile, hardness, impact)

- Microstructure examination to ensure α+β phase uniformity

- Biocompatibility and cytotoxicity testing for implant compliance

Full traceability from raw material lot to final delivery ensures product reliability for medical implant manufacturers.

Application Advantages

1. Artificial joints – titanium is widely used in the manufacturing of hip, knee, and shoulder implants.

2. Dental implants – titanium is ideal for dental implants due to its excellent biocompatibility.

3. Spinal devices – titanium rods and screws are used in spinal fusion surgery to aid in the healing process.

4. Maxillofacial surgery – titanium plates and screws are used in mandibular and maxillary surgery.

Shaanxi Chuanghui Daye Metal Material CO.,Ltd (Chdymetal )supplies premium medical-grade titanium bars with comprehensive specifications. Standard models are readily available, featuring expedited delivery within 1-5 working days. Contact us for detailed specifications.

R&D and Customization

We offer tailored research and development services for medical device manufacturers seeking customized titanium materials. Our R&D team works closely with customers to:

- Develop new alloy compositions for improved fatigue life

- Optimize microstructure and mechanical behavior

- Provide custom bar dimensions, surface finish, and tolerance

- Conduct simulation and in-vitro testing support

Our continuous innovation ensures that every Medical Titanium Bar meets the evolving needs of modern medical technology.

Packaging & Logistics

To ensure safety and cleanliness, Medical Titanium Bars are vacuum-packed or sealed in clean-room environments.

- Packaging Options: Plastic film wrap, vacuum seal, wooden or steel boxes.

- Labeling: Lot number, grade, size, and inspection certificate included.

- Shipping: Global logistics support by air or sea with custom export documentation.

Each package is protected against moisture, contamination, and mechanical damage during transportation.

|

|

|

|

|

|

|

|

|

|

|

|

Global Cooperation& Certification

We supply Medical Titanium Bars to global medical implant manufacturers, research institutions, and OEM partners across Europe, the United States, Japan, and South Korea.

Our company holds the following certifications:

- ISO 9001 Quality Management System

- ISO 13485 Medical Device Manufacturing Certification

- CE and SGS Product Testing Certificates

Through long-term cooperation with leading biomedical companies, we have established a global reputation for excellence in titanium materials for healthcare applications.

|

|

|

|

|

|

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email