- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

molybdenum alloy wire

2. Diameter: 0.05–5 mm

3. Length: up to 1000 mm

4. Tensile strength: 550–750 MPa

5. Density: 10.2–11 g/cm³

6. Applications: Aerospace, electronics

7. Heat resistant

Molybdenum Alloy Wire - Premium Quality for Industrial Applications

Product Introduction

When you need reliable, high-performance molybdenum alloy wire for demanding applications, Shaanxi Chuanghui Daye Metal Material delivers exceptional quality. Our molybdenum alloy wire combines the superior properties of molybdenum with specialized alloying elements to create products that excel in extreme environments. With over 30 years of experience in rare metal manufacturing, we provide wire solutions that meet your most challenging requirements.

Our advanced manufacturing processes ensure consistent quality and performance. Each wire undergoes rigorous testing to guarantee it meets industry standards. You can trust our products for critical applications in aerospace, electronics, and high-temperature environments.

Key Features and Benefits

- Exceptional High-Temperature Strength: Maintains mechanical properties at extreme temperatures

- Superior Thermal Conductivity: Efficient heat transfer for optimal performance

- Low Thermal Expansion: Dimensional stability across temperature ranges

- Excellent Corrosion Resistance: Long-lasting performance in harsh environments

- Customizable Specifications: Tailored to your specific application needs

- Consistent Quality: Uniform properties throughout the entire length

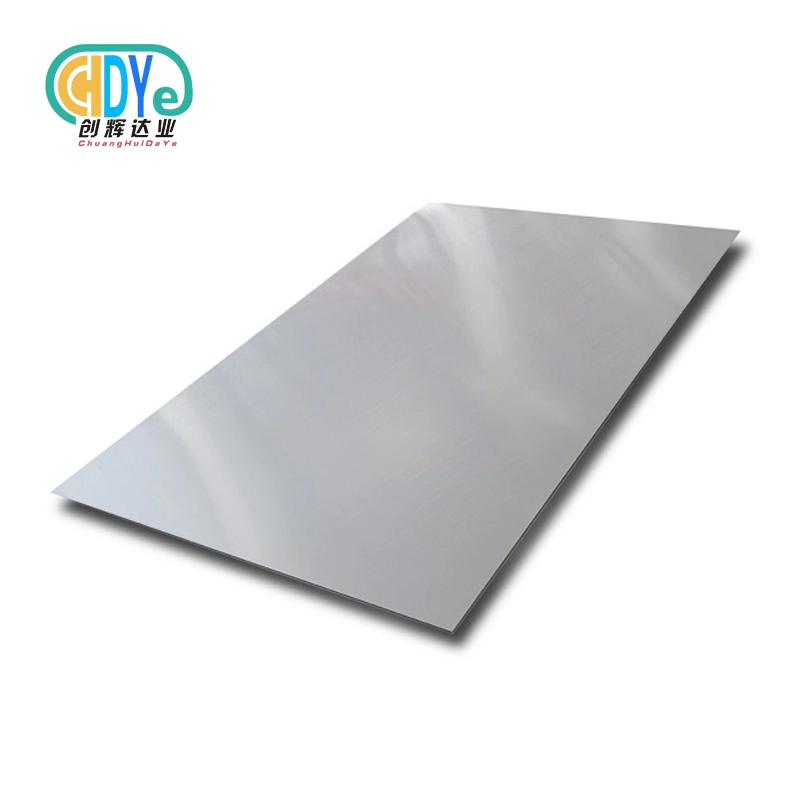

Technical Specifications

|

Material |

Mo, MoLa, etc. |

|

Standard |

ASTM F 289,ASTM B 289 |

|

Size |

φ0.08~φ3mm×L |

|

Purity |

99.95% |

|

Density |

10.2g/cm³ |

|

Surface |

Black Wire, Bright Wire |

|

Technology Process |

Forged, Drawn, Polished |

|

Certification |

ISO9001:2015 |

| Production time | 7-15days according to your quantity |

| Scope of application | Heating elements, high-temperature components, wire cutting, etc. |

Chemical composition

|

Grade |

Chief constituent % |

The impurity content is not more than % |

|||||||||||

|

Mo |

Ti |

Zr |

C |

Al |

Ca |

Fe |

Mg |

Ni |

Si |

C |

N |

O |

|

|

Mo1 |

|

- |

- |

- |

0.002 |

0.002 |

0.010 |

0.002 |

0.005 |

0.01 |

0.01 |

0.003 |

0.008 |

|

Mo2 |

|

- |

- |

- |

0.005 |

0.004 |

0.015 |

0.005 |

0.005 |

0.01 |

0.02 |

0.003 |

0.020 |

|

TZM |

|

0.4- |

0.06- |

0.01- |

0.002 |

0.002 |

0.01 |

0.001 |

0.005 |

0.005 |

- |

0.002 |

0.05 |

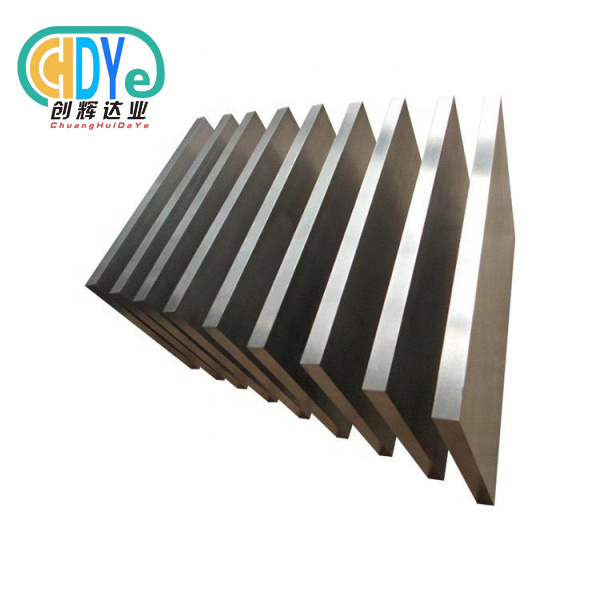

Manufacturing Process

Our state-of-the-art production facility follows strict quality control protocols. The process begins with high-purity powder metallurgy techniques. We press raw materials into ingots, then draw them through precision dies to achieve your required dimensions.

Each step includes quality checkpoints to ensure consistency. Our experienced technicians monitor the entire process, from initial forming to final inspection. This attention to detail guarantees you receive products that meet or exceed specifications.

|

|

|

|

|

|

|

|

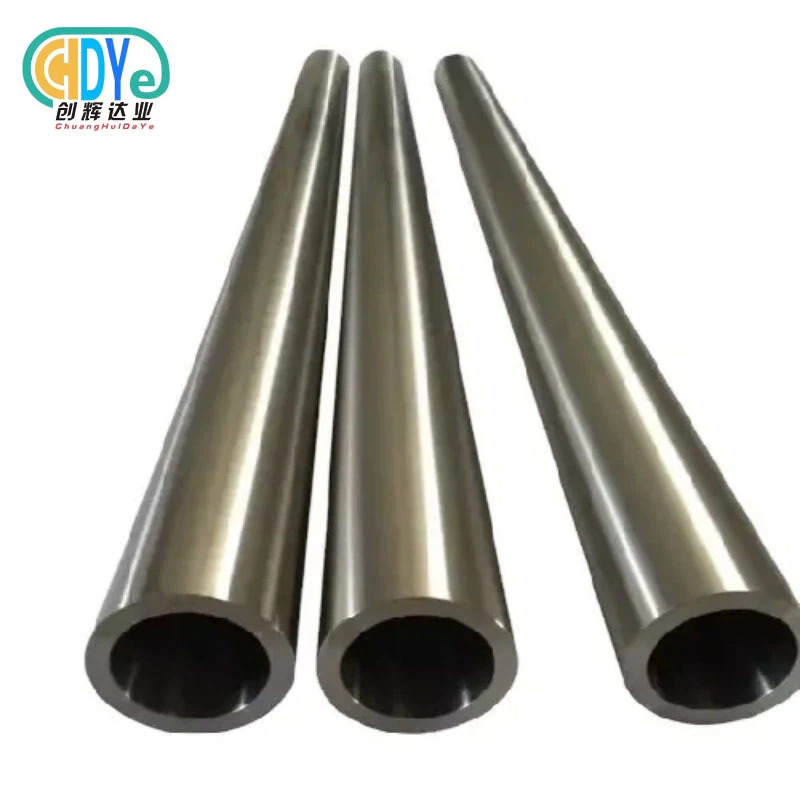

Applications and Industries

Aerospace Industry: Structural components, engine parts, and high-temperature applications where reliability is critical.

Electronics Sector: Heating elements, electrical contacts, and specialized conductors requiring thermal stability.

Medical Equipment: Precision instruments and devices demanding biocompatibility and durability.

Research and Development: Laboratory equipment and experimental setups requiring consistent performance.

Industrial Furnaces: Heating elements and support structures for extreme temperature operations.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain tight dimensional tolerances to ensure your components fit perfectly. Standard tolerance ranges from ±0.01mm to ±0.05mm depending on diameter. Custom tolerances available upon request.

Length cutting accuracy: ±1mm for standard orders. Precision cutting available for critical applications.

Product Features in Detail

The unique properties of our molybdenum alloy wire make it ideal for applications where standard materials fail. Its low coefficient of thermal expansion prevents warping and distortion during temperature cycling.

The excellent electrical conductivity ensures efficient current flow with minimal energy loss. This combination of properties makes it perfect for heating elements and electrical components.

Our alloy compositions provide enhanced mechanical properties compared to pure molybdenum. You get improved ductility without sacrificing high-temperature performance.

Quality Assurance and Testing

Every batch undergoes comprehensive testing including:

- Tensile strength verification

- Dimensional accuracy checking

- Chemical composition analysis

- Surface quality inspection

- Electrical property testing

We maintain detailed quality records for traceability. Our quality management system ensures consistent product performance.

|

|

|

OEM & Customization Services

We understand that standard specifications don't always meet your unique requirements. Our technical team works closely with you to develop custom solutions.

Whether you need specific alloy compositions, unique dimensions, or special surface treatments, we can accommodate your needs. Our flexible manufacturing capabilities allow for both small prototype quantities and large production runs.

Packaging and Shipping

Products are carefully packaged to prevent damage during transit. We use specialized protective materials for delicate small-diameter wires.

Shipping options include standard ground delivery and expedited services for urgent orders. International shipping available to over 50 countries worldwide.

Why Choose Us

Located in Baoji, China's "Titanium Capital," we have access to premium raw materials and specialized expertise. Our founder's 30+ years of industry experience ensures you receive knowledgeable support.

We focus on building long-term partnerships through reliable quality, competitive pricing, and responsive customer service. Our products serve customers across the United States, Germany, South Korea, Singapore, and many other countries.

|

|

|

|

|

|

FAQs

Q: What's the minimum order quantity?

A: We accommodate both small prototype orders and large production quantities.

Q: Can you provide material certificates?

A: Yes, we provide detailed material certificates with chemical composition and mechanical properties.

Q: What's the typical lead time?

A: Standard products ship within 1-2 weeks. Custom specifications may require additional time.

Contact Us

Ready to discuss your molybdenum alloy wire requirements? Our technical team is here to help you select the right specifications for your application.

Contact us today at info@chdymetal.com for quotes, technical support, or any questions about our products. We look forward to partnering with you for your metal material needs.

Learn about our latest products and discounts through SMS or email