- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

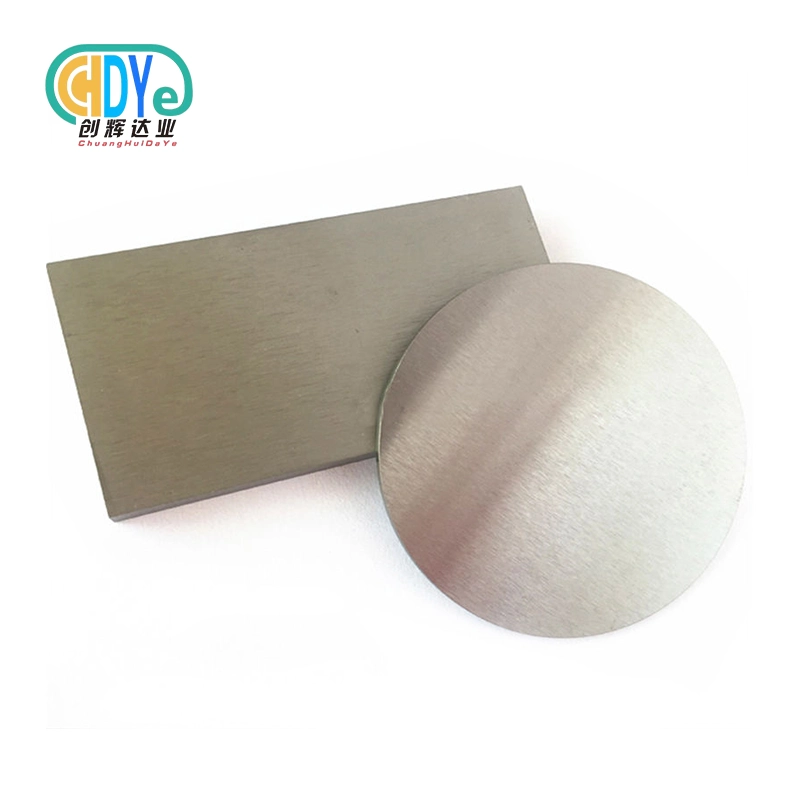

gr7 titanium alloy sheet

2. Thickness 0.5-50mm

3. Density 4.51 g/cm³

4. Tensile strength 480 MPa

5. Corrosion resistant

6. Chloride environment use

7. Chemical industry applications

Looking for exceptional corrosion resistance in demanding environments? Our gr7 titanium alloy sheet delivers unmatched performance where other materials fail. This premium titanium grade combines the lightweight strength of titanium with enhanced palladium content for superior chemical resistance. You'll find this material perfect for chemical processing, marine applications, and industrial equipment that faces harsh conditions daily.

Key Features and Benefits

Outstanding Corrosion Resistance

The palladium addition makes this alloy the most corrosion-resistant titanium grade available. You can rely on it in acidic and chloride environments where standard materials would deteriorate quickly.

Lightweight Yet Strong

With a density of only 4.51 g/cm³, you get excellent strength-to-weight ratio. This means reduced structural weight without compromising performance in your applications.

Excellent Fabricability

Our sheets offer superior weldability and formability. You can machine, bend, and shape them easily for complex component manufacturing.

Biocompatible Properties

Safe for medical and food processing applications where material purity matters most.

Technical Specifications

Chemical compositaion

|

|

N |

C |

H |

Fe |

O |

Al |

V |

Pa |

Mo |

Ni |

Ti |

|

Gr 1 |

0.03 |

0.08 |

0.015 |

0.20 |

0.18 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 2 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 3 |

0.05 |

0.08 |

0.015 |

0.30 |

0.35 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 4 |

0.05 |

0.08 |

0.015 |

0.50 |

0.40 |

/ |

/ |

/ |

/ |

/ |

|

|

Gr 5 |

0.05 |

0.08 |

0.015 |

0.40 |

0.20 |

5.5~6.75 |

3.5~4.5 |

/ |

/ |

/ |

bal |

|

Gr 7 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

0.12~0.25 |

/ |

/ |

bal |

|

Gr 9 |

0.03 |

0.08 |

0.015 |

0.25 |

0.15 |

2.5~3.5 |

2.0~3.0 |

/ |

/ |

/ |

bal |

|

Gr12 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

0.2~0.4 |

0.6~0.9 |

|

Mechanical Properties

|

Grade |

Status |

Tensile Strength |

Yield Strength |

Elongation |

Area of Reducation |

||

|

Ksi |

Mpa |

Ksi |

Mpa |

% |

|||

|

≥ |

|||||||

|

GR1 |

Annealed |

35 |

240 |

25 |

170 |

24 |

30 |

|

GR2 |

50 |

345 |

40 |

275 |

20 |

30 |

|

|

GR3 |

65 |

450 |

55 |

380 |

18 |

30 |

|

|

GR4 |

80 |

550 |

70 |

483 |

15 |

25 |

|

|

GR5 |

130 |

895 |

120 |

828 |

10 |

25 |

|

|

TI-6AL-4VELI |

125 |

860 |

115 |

795 |

10 |

25 |

|

|

GR6 |

120 |

828 |

115 |

483 |

15 |

25 |

|

|

GR7 |

50 |

345 |

40 |

275 |

20 |

30 |

|

|

GR9 |

90 |

620 |

70 |

483 |

15 |

25 |

|

|

GR11 |

35 |

240 |

25 |

170 |

24 |

30 |

|

|

GR12 |

70 |

483 |

50 |

345 |

18 |

25 |

|

Available Grades and Materials

We specialize in titanium Grade 7 sheets with consistent palladium content for optimal corrosion resistance. Our material meets ASTM B265 standards and comes in various surface finishes including hot rolled, cold rolled, and pickled surfaces.

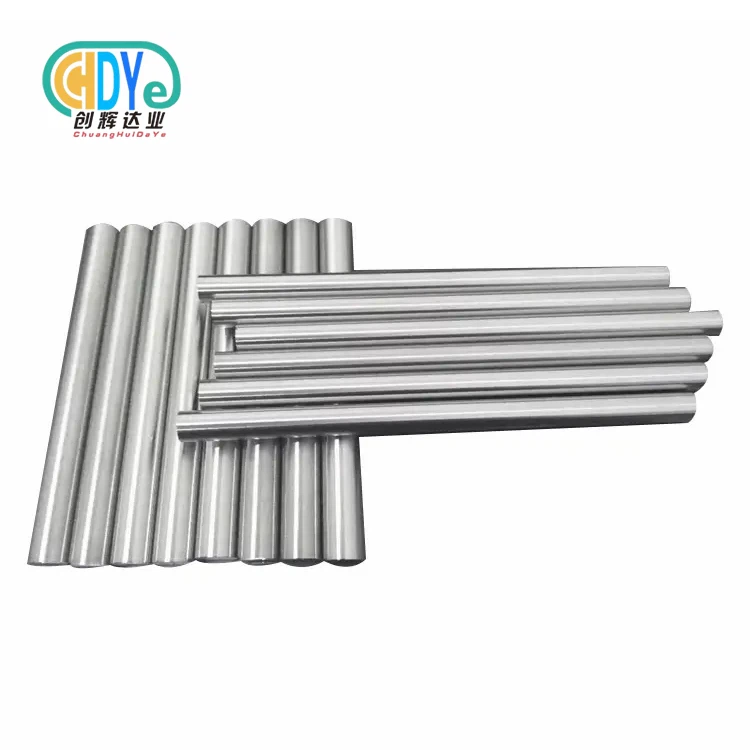

Manufacturing Process

Our gr7 titanium alloy sheet undergoes precise manufacturing steps. We start with high-purity titanium ingots, add controlled palladium content, then hot roll and cold roll to your specified thickness. Each sheet receives proper annealing treatment to ensure optimal mechanical properties and stress relief.

Applications and Industries

Chemical Processing

Reactor vessels, heat exchangers, and piping systems benefit from exceptional chemical resistance.

Marine Industry

Seawater desalination equipment, offshore platforms, and marine hardware rely on this material's chloride resistance.

Pollution Control

Air and water treatment systems use these sheets for long-term durability in corrosive environments.

Medical Equipment

Surgical instruments and implant components leverage the biocompatible properties.

Product Dimensions and Tolerances

Thickness Tolerance: ±0.05mm for sheets under 3mm, ±0.1mm for thicker sheets

Width Tolerance: ±3mm

Length Tolerance: ±5mm

Flatness: 2mm per meter maximum deviation

Be used in a wide range of industries.

Metallurgy and Special Steel

Electronics and Semiconductors

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Features in Detail

The palladium addition in our gr7 titanium alloy sheet creates a passive oxide layer that resists breakdown in reducing acids. You'll notice superior performance in hydrochloric acid, sulfuric acid, and hot brine solutions compared to other titanium grades.

The material maintains strength at elevated temperatures while resisting stress corrosion cracking. This makes it ideal for pressure vessels and heat transfer equipment operating under demanding conditions.

Quality Assurance and Testing

Every sheet undergoes rigorous testing including chemical composition analysis, mechanical property verification, and surface quality inspection. We provide mill test certificates with each shipment documenting compliance with international standards.

Ultrasonic testing ensures internal soundness while dimensional inspection confirms tolerance compliance. Our quality system ensures consistent material properties across all production batches.

|

|

|

OEM & Customization Services

We offer custom cutting, machining, and forming services to meet your specific requirements. Whether you need precision blanks, formed components, or special surface treatments, our technical team can support your project from design to delivery.

Packaging and Shipping

Sheets are carefully packaged with protective interleaving to prevent surface damage. We use wooden crates for international shipping and provide proper documentation for customs clearance. Delivery typically occurs within 1-2weeks depending on specifications.

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us

With over 30 years of rare metal experience, Shaanxi Chuanghui Daye Metal Material Co., Ltd. brings deep expertise to every order. Located in China's "Titanium Capital," we have direct access to premium raw materials and advanced processing facilities.

Our customers in over 50 countries trust us for consistent quality, competitive pricing, and reliable delivery. We focus on building long-term partnerships through exceptional service and technical support.

|

|

|

|

|

|

FAQs

Q: What makes Grade 7 different from other titanium grades?

A: The palladium addition provides superior corrosion resistance, especially in reducing acid environments.

Q: Can you provide small quantities for prototyping?

A: Yes, we accommodate both small prototype orders and large production quantities.

Q: What certifications do you provide?

A: We supply mill test certificates and can arrange third-party testing when required.

Contact Us

Ready to discuss your gr7 titanium alloy sheet requirements? Our technical team is here to help you select the right specifications for your application.

Email: info@chdymetal.com

Contact us today for competitive pricing and expert guidance on your titanium material needs.

Learn about our latest products and discounts through SMS or email