- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Application Of Titanium Alloys

Application of titanium alloys

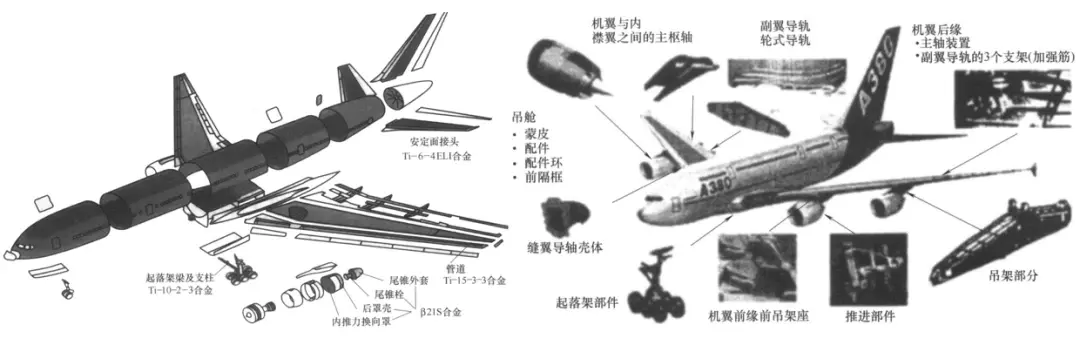

01 Titanium alloys for aircraft

Titanium alloys not only have high specific strength, but also have the advantages of wide operating temperature range, good corrosion resistance, and electrochemical compatibility with polymer-based composite materials, which can effectively reduce the weight of aircraft. Titanium is an indispensable raw material in aircraft fuselages and engine components, and the amount of titanium used in aircraft accounts for about half of the global titanium production.

02 Titanium alloys for aerospace

Industrial pure titanium and Ti-6AI-4V, Ti-5AI-2.5Sn, Ti-6AI-4V ELI, Ti-5AI-2.5SnELI, Ti-7A1-4Mo, Ti-3A1-2.5V, Ti-15V-3Cr-3Sn-3A1, Ti-13V-11Cr-3A1, Ti/B-Al composite materials are widely used in the aerospace field.

Titanium and titanium-based alloys are used in aerospace vehicle structural parts such as missiles, launch vehicles, artificial satellites, and spacecraft, achieving the goal of reducing launch weight, increasing range, and saving launch costs. In rockets and missiles, titanium alloys are mainly used for fuel tanks, rocket engine casings and rings, rocket nozzle sleeves, etc. In artificial satellites, titanium alloys are mainly used for shells, support frames, fuel tanks, recovery cabin end frames, etc. Titanium-nickel shape memory alloys can be used for temperature control system components, and titanium castings can be used for resource satellite camera frames.

Learn about our latest products and discounts through SMS or email