- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

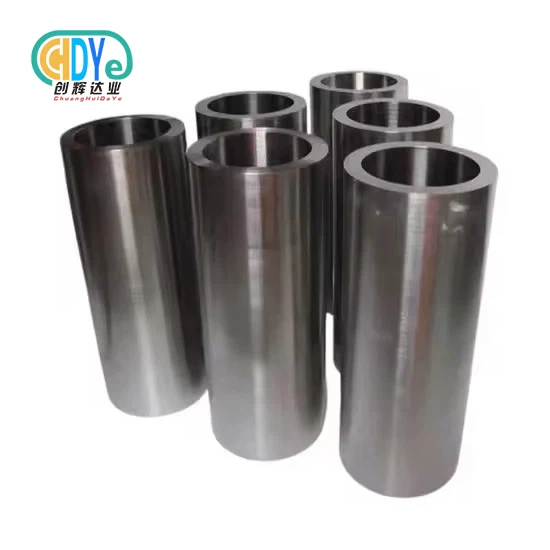

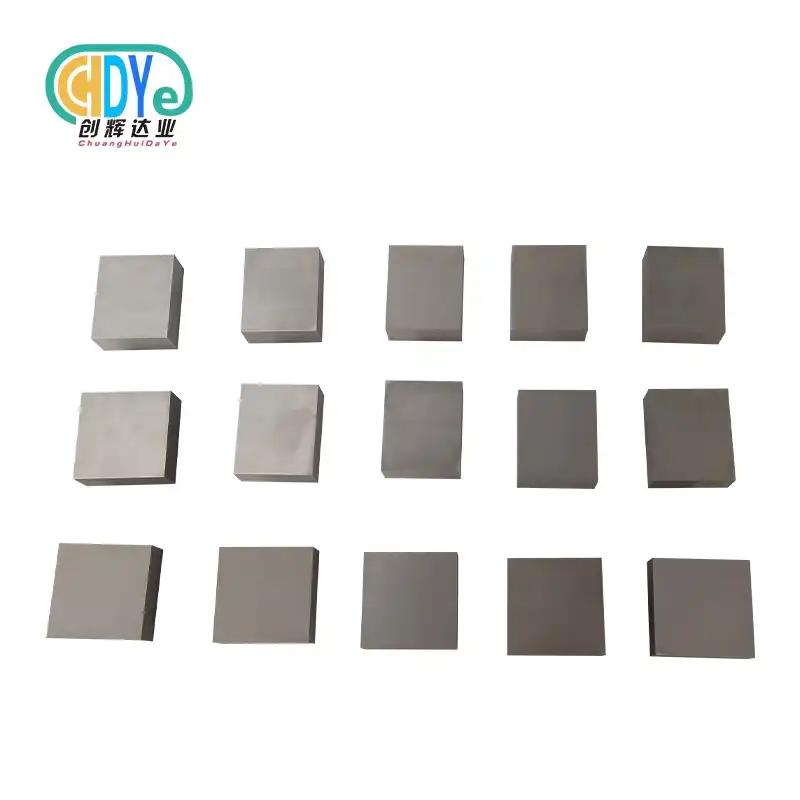

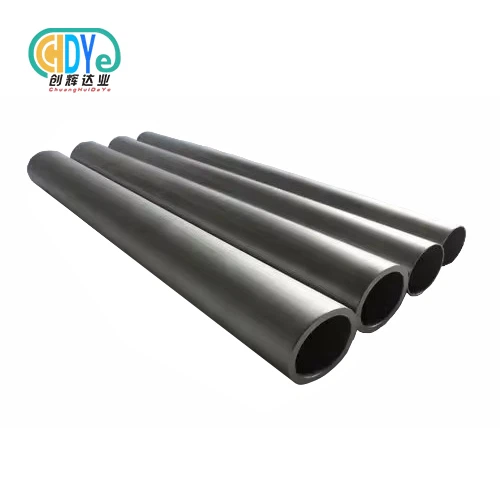

Titanium Square Bar

Shape: Square

Specification: customized as your request

State: annealed

Surface:Bright/Polished/ Machined

Product Details

Our titanium square bar products are developed to meet the diverse requirements of industrial applications where precision, corrosion resistance, and mechanical stability are critical. Each bar undergoes advanced forging and heat treatment processes to ensure uniform grain structure and consistent mechanical properties.

With grades ranging from commercially pure titanium (Gr1, Gr2, Gr4) to high-strength titanium alloys (Gr5, Gr9, Gr23), we can deliver solutions for both lightweight structural needs and demanding aerospace environments.

All bars are manufactured according to international standards such as ASTM B348, AMS 4928, and ISO 5832, ensuring excellent compatibility for global users.

Products Parameter

Grade: Gr1 Gr2 Gr3 Gr4 Gr5 Gr7 Gr9 Gr11 Gr12 Gr23 etc

Shape: Square

Specification: customized as your request

State: annealed

Surface: Bright/Polished/ Machined

Main Technique: Hot Forged; Hot Rolled; Cold drawn; Straighten etc

Application: Metallurgy, Electronics, Medical, Chemical, Petroleum, Pharmaceutical, aerospace, etc.

Type of titanium bar

|

|

|

|

Why choose our products?

Titanium bar we have various size in stock and customized service is provided.

Manufacturing & Processing Capability

Shaanxi Chuanghui Daye Metal Material Co., Ltd. operates advanced equipment including vacuum melting furnaces, hot forging presses, precision rolling mills, and CNC lathes. These facilities allow us to control every production stage — from melting, forging, and rolling to machining and polishing.

Our skilled technicians monitor temperature, deformation, and microstructure to maintain high accuracy and repeatability in each titanium billet. The final products are straightened, surface-treated, and inspected to meet the strictest dimensional and performance standards.

|

|

|

|

|

|

|

|

Surface & Mechanical Performance

Depending on customer requirements, the titanium bar can be supplied in various surface conditions such as:

- Bright finish: mirror-like appearance suitable for decorative and precision use.

- Polished finish: improved corrosion resistance and visual quality.

- Machined finish: tight dimensional tolerance for mechanical parts.

Mechanical strength, hardness, and ductility are fully tested before shipment to ensure superior consistency and reliability in end applications.

Quality Assurance

All raw materials are verified by chemical composition analysis and mechanical property testing before entering production. Each batch of forged titanium bar undergoes ultrasonic inspection to detect internal defects, ensuring zero compromise in quality.

We are certified to ISO 9001:2015, guaranteeing strict adherence to quality management and traceability. Material test reports (MTC), ultrasonic inspection certificates, and dimensional inspection records can be provided upon request.

Application Advantages

Our titanium alloy bar products deliver significant performance benefits across multiple industries:

- Aerospace & Defense: lightweight, fatigue-resistant parts for aircraft and spacecraft.

- Medical & Dental: biocompatible material ideal for implants and surgical instruments.

- Chemical Engineering: corrosion-resistant components for acid, alkali, and seawater environments.

- Marine Industry: durable and anti-corrosive for offshore structures and seawater systems.

- Energy & Power: high-conductivity material for renewable energy equipment and condenser systems.

These bars are widely recognized for their long service life and cost efficiency, even in harsh operating conditions.

Be used in a wide range of industries.

Metallurgy and Special Steel

Electronics and Semiconductors

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

R&D and Customization

Our engineering team continuously explores improvements in titanium forging technology and surface finishing techniques to meet the evolving needs of high-tech industries.

We offer:

- Tailored sizes and cross-sections

- Machining per customer drawings

- Prototype and small-batch manufacturing

- Customized alloy compositions for special applications

OEM and ODM services are available for industrial, aerospace, and medical users worldwide.

Packaging & Logistics

Each custom titanium bar is packaged in anti-rust film and foam protection before being sealed in export-grade wooden crates. Detailed labels include product grade, size, lot number, and inspection mark to ensure full traceability.

With over 50 export destinations — including the United States, Germany, France, Korea, Japan, and Singapore — we guarantee safe and fast global delivery by air, sea, or land transportation.

Package of titanium square bar

Global Cooperation& Certification

We have established long-term partnerships with customers across Europe, North America, and Asia. Our products have earned wide recognition for their high purity, stable performance, and excellent service support.

Whether you are a distributor, manufacturer, or end user, we welcome cooperation and joint development of titanium-based solutions for future industries.

|

|

|

|

|

|

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

We are ready to supply high-quality titanium square bar with fast delivery, competitive pricing, and professional service to customers worldwide.

Learn about our latest products and discounts through SMS or email