- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

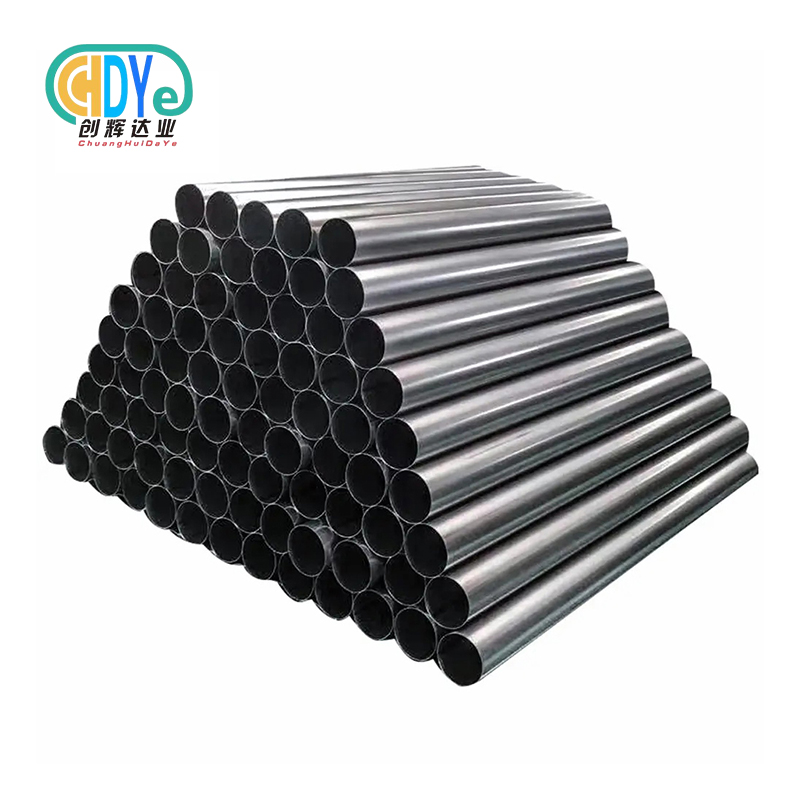

Niobium Round Bar

2.Grade:RO4200, RO4210

3.purity: 99.99%

Product Introduction

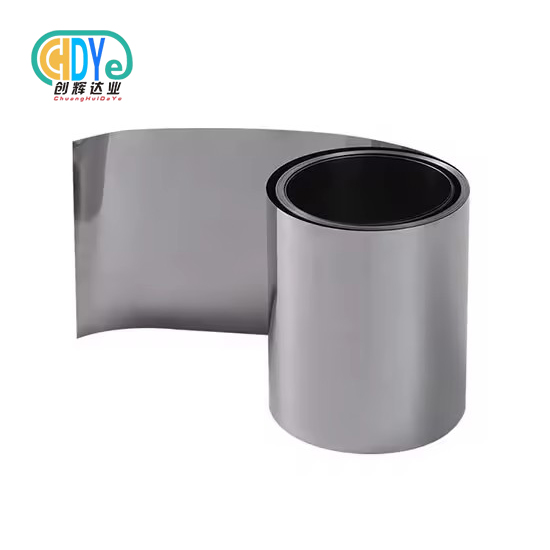

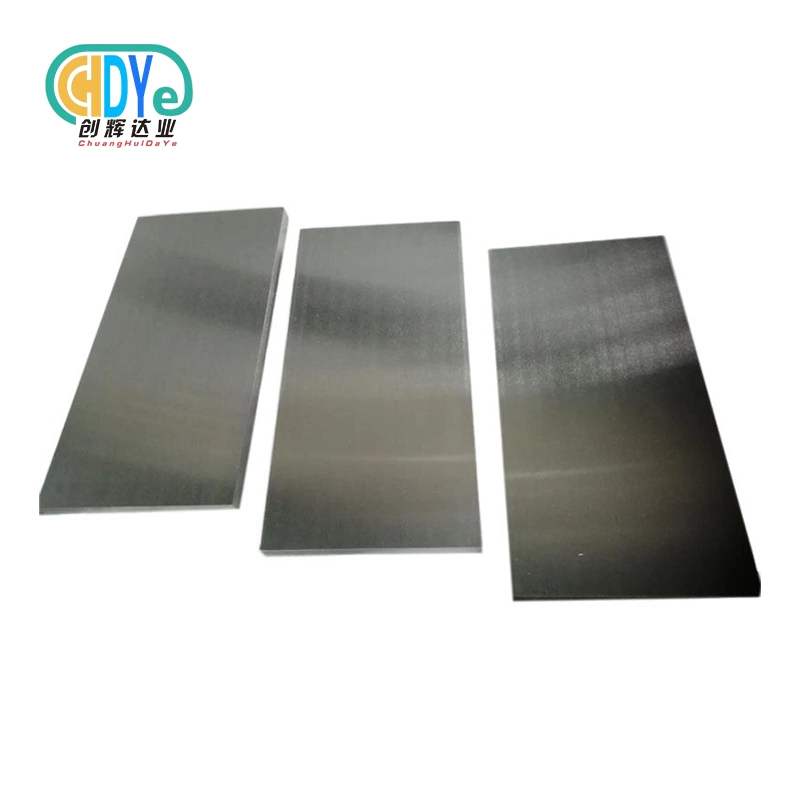

The Niobium Round Bar provided by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is made from high-purity niobium, offering excellent corrosion resistance, high melting point, and superior mechanical properties. Each Niobium Round Rod is precision-forged and machined to ensure consistent diameter, smooth surface finish, and reliable performance. These features make the Niobium Round Rod suitable for high-demand industrial applications where quality and durability are essential.

Niobium has a density of 8.57g/cm³, a melting point of 2477°C, and a boiling point of 4744°C. Niobium is a silver-gray, soft and ductile rare high melting point metal. Because niobium has good superconductivity, high melting point, corrosion resistance, wear resistance and other characteristics, it is widely used in steel, superconducting materials, aerospace, atomic energy and other fields.

Standard:ASTM B 392-95

Grade:R04200, R04210

purity: 99.95%

Length: As your requirements

Niobium Round Bar Mechanical Properties

|

Grade |

Tensile strength psi(MPa), ≥ |

Yield strength δ0.2, psi (MPa),≥ |

Elongation in 1"/2" gage length, %, ≥ |

|

|

>=0.010 |

<0.010 |

|||

|

R04200 R04210 |

18000 (125) |

12000 (85) |

25 |

20 |

Niobium round bar common stock

You can find the normal stock always and usually we can arrange delivery on the same day.we will also support your sample order.

|

Grade |

Standard |

Specification (mm) |

|

R04200 |

ASTM B 392 |

Dia 8-10*L3000 |

|

R04200 |

ASTM B 392 |

Dia 10*L1000 |

|

R04200 |

ASTM B 392 |

Dia9-12mm*L1165-2340 |

|

R04200 |

ASTM B 392 |

Dia20*3010 |

|

R04200 |

ASTM B 392 |

Dia15-22*L1085-2030 |

|

R04210 |

ASTM B 392 |

Dia 40*L3000 |

|

R04210 |

ASTM B 392 |

Dia 50-80*L3000 |

|

R04210 |

ASTM B 392 |

Dia 340*850 |

Application Advantages

The Niobium Round Bar is widely used in various industries:

- Aerospace & Defense: Structural components, superconducting magnets, and high-temperature equipment.

- Electronics & Semiconductors: Electrodes, connectors, and conductive components.

- Medical Equipment: Surgical tools, implants, and biocompatible devices.

- Chemical Processing: Corrosion-resistant piping, reactors, and vessels.

- Energy & Environmental Engineering: Heat exchangers, renewable energy equipment, and specialized industrial machinery.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

The production process of Niobium Round Bar includes:

- Raw Material Selection: Only high-purity niobium ingots are chosen.

- Vacuum Melting: Ensures material uniformity and impurity removal.

- Hot Forging & Rolling: Converts ingots into preliminary bar shapes.

- Precision Machining: Achieves exact diameters and tight tolerances.

- Annealing: Enhances ductility and mechanical properties.

- Surface Finishing & Inspection: Ensures smooth and defect-free surfaces on each Niobium Round Bar.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Every Niobium Round Bar undergoes strict quality control procedures:

- Chemical Analysis: Confirms high-purity niobium composition.

- Mechanical Testing: Includes tensile strength, elongation, and hardness checks.

- Dimensional Inspection: Ensures correct diameter, roundness, and length.

- Surface Examination: Detects scratches, pits, or surface defects.

- Non-Destructive Testing: Verifies internal integrity.

R&D and Customization

Our R&D team supports customized solutions for Niobium Round Bar:

- Special diameters, lengths, and surface finishes.

- Alloy optimization for industry-specific requirements.

- Prototype and small-batch production.

- Technical guidance and material selection assistance.

Packaging & Global Logistics

To protect the Niobium Round Bar during transit:

- Wrapped in vacuum or anti-rust film

- Supported with foam or braces to prevent deformation

- Packed in export-standard wooden crates with clear labels

- Delivered via reliable air, sea, or land transportation to global destinations

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye provides OEM and custom services for Niobium Round Bar:

- Custom diameters, lengths, and mechanical properties

- Small or large-scale production according to customer specifications

- Full technical consultation and after-sales support

- Solutions for aerospace, medical, energy, and chemical industries

Inspection Process

The inspection workflow for Niobium Round Bar includes:

- Incoming Material Verification

- In-Process Monitoring during forging, rolling, and machining

- Dimensional & Surface Checks at multiple stages

- Mechanical & Chemical Testing

- Final Packaging Inspection

This ensures that every Niobium Round Bar delivered is reliable and quality-assured.

Why Choose Us

- 30+ Years of Expertise in rare metal materials

- ISO 9001:2015 Certified quality management system

- Advanced Manufacturing Equipment including electron beam furnaces and rolling machines

- 7-Day Fast Delivery for standard specifications

- Global Export Network to over 50 countries

- OEM & Technical Support for customized solutions

Choosing Chuanghui Daye guarantees premium Niobium Round Bar with professional support.

|

|

|

|

|

|

FAQs

Q1: What standards does the Niobium Round Bar meet?

A1: All bars are produced according to ASTM, ISO, and international specifications.

Q2: Can I order custom sizes?

A2: Yes, we provide full customization for Niobium Round Bar.

Q3: How is quality ensured?

A3: Through chemical analysis, mechanical testing, dimensional checks, and non-destructive testing.

Q4: What is the lead time for Niobium Round Bar?

A4: Standard bars ship within 7 days; custom orders depend on specifications.

Q5: Do you offer international shipping?

A5: Yes, we provide reliable air, sea, and land logistics worldwide.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email