- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

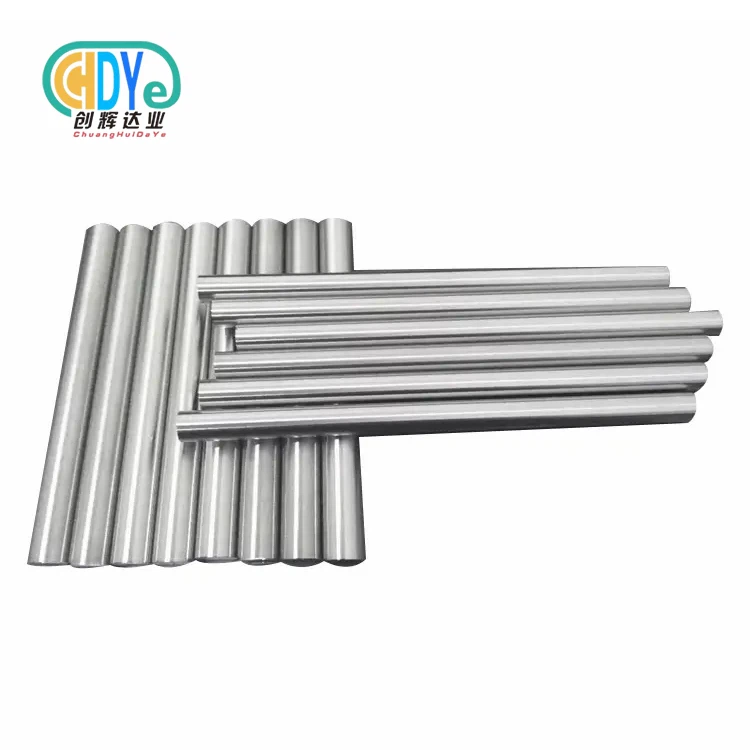

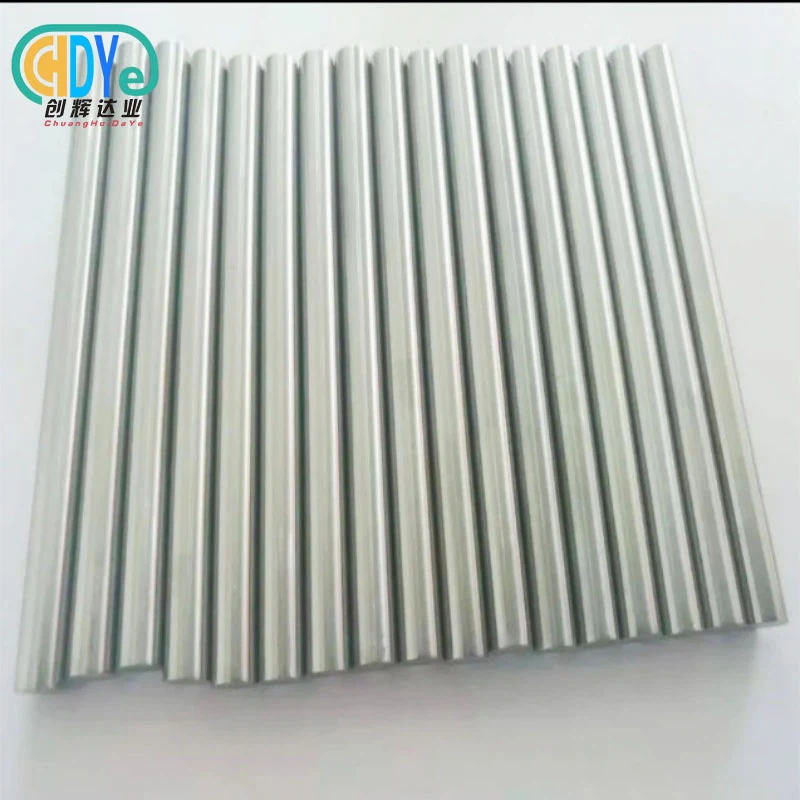

niobium seamless tube

2. Standard: ASTM B 394

3. State: Hard, semi-hard and soft

4. Dimension: as your customized

5.Certificate: ISO 9001:2015

Product Introduction

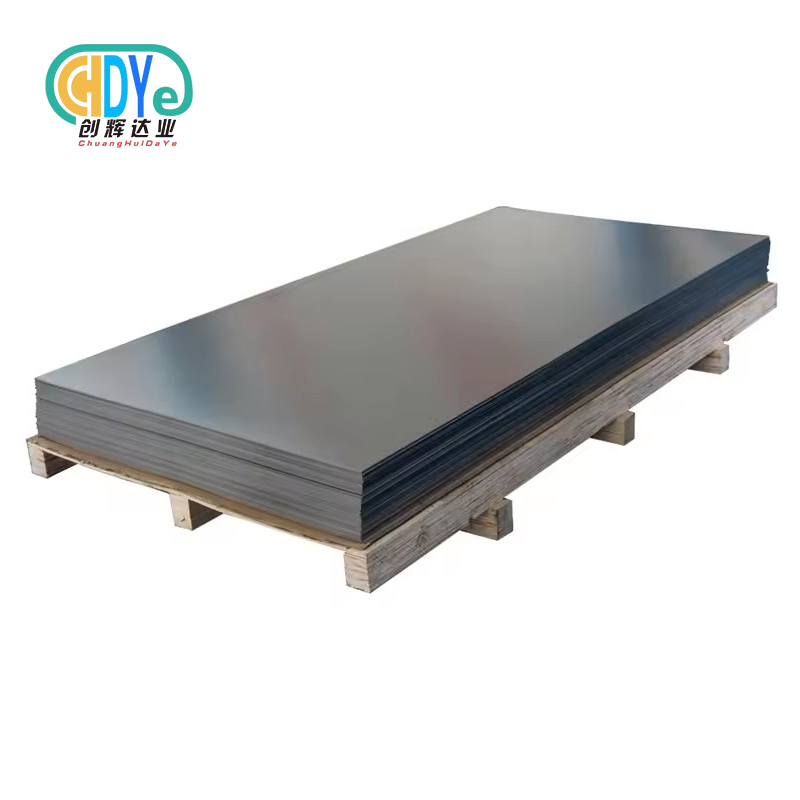

Welcome to Shaanxi Chuanghui Daye Metal Material Co., Ltd.'s premium niobium seamless tube collection. Our high-purity niobium tubes are manufactured using advanced seamless technology, ensuring superior strength and reliability for your critical applications. With over 30 years of experience in rare metal processing, we deliver exceptional quality tubes that meet the most demanding industrial requirements. Each tube is crafted from solid niobium billets through precision extrusion processes, eliminating weak points and ensuring consistent performance across all applications.

Key Features and Benefits

- Superior Strength: No welded seams mean enhanced structural integrity

- High Purity: Niobium content exceeds 99.9% for optimal performance

- Corrosion Resistance: Excellent resistance to harsh chemical environments

- Temperature Stability: Maintains properties at extreme temperatures

- Smooth Interior: Reduced contamination risk and easier cleaning

- Custom Dimensions: Tailored to your specific project requirements

Technical Specifications

| Property | Specification |

|---|---|

| Alloy Purity | Nb >99.9% |

| Outer Diameter | 10–100 mm |

| Wall Thickness | 0.3–10 mm |

| Maximum Length | up to 3000 mm |

| Density | 8.57 g/cm³ |

| Manufacturing Type | Seamless |

| Surface Finish | Polished/As-rolled |

| Condition | Annealed |

| Standard | ASTM B 394 |

| Certificate | ISO 9001:2015 |

| Production time | Normal production time need about 10-15 working days |

| Payment terms | 30%TTin advance,70% balance payment before shipment |

Available Grades and Materials

Our tubes are manufactured from high-purity niobium grades that comply with international standards. We source our raw materials from certified suppliers to ensure consistent quality and performance. Each grade is carefully selected based on your application requirements and environmental conditions.

Seamless Niobium pipe we can supply as below information:

|

Out diameter |

10-100mm |

|

Wall thickness |

0.3-10.0mm |

|

Length |

200mm-6000mm |

Chemical composition

|

Main elements(%) |

Impurities (Maximum %) |

||||||||||

|

Nb |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Ta |

O |

C |

H |

N |

|

Remainder |

0.004 |

0.004 |

0.002 |

0.005 |

0.005 |

0.002 |

0.07 |

0.015 |

0.0040 |

0.0015 |

0.003 |

|

Remainder |

0.01 |

0.01 |

0.005 |

0.02 |

0.01 |

0.004 |

0.10 |

0.02 |

0.01 |

0.0015 |

0.01 |

Manufacturing Process

Our seamless manufacturing process begins with high-quality niobium billets. The material is heated to precise temperatures and extruded through specialized dies to create hollow forms. This process eliminates the need for welding, resulting in tubes with superior mechanical properties and uniform wall thickness throughout the entire length.

|

|

|

|

|

|

|

|

Applications and Industries

Aerospace: Rocket nozzles, satellite components, and propulsion systems

Electronics: Superconducting applications and electronic components

Chemical Processing: Corrosion-resistant piping for harsh environments

Medical: Biocompatible implants and surgical instruments

Research: Laboratory equipment and scientific instruments

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain strict dimensional tolerances to ensure your tubes meet exact specifications. Our quality control systems monitor every aspect of production, from initial material inspection through final dimensional verification. Standard tolerances are available, with tighter tolerances possible for specialized applications.

Product Features in Detail

The seamless construction of our niobium tubes provides distinct advantages over welded alternatives. The absence of seams eliminates potential failure points and ensures consistent pressure ratings throughout the tube length. The smooth interior surface reduces turbulence and contamination risks, making these tubes ideal for high-purity applications.

Quality Assurance and Testing

Every niobium seamless tube undergoes comprehensive testing including dimensional verification, chemical composition analysis, and mechanical property testing. Our quality management system ensures consistent product performance and reliability. We maintain detailed traceability records for every batch produced.

|

|

|

OEM & Customization Services

We understand that every application has unique requirements. Our experienced engineering team works closely with you to develop custom solutions. Whether you need specific dimensions, surface treatments, or specialized packaging, we can accommodate your needs while maintaining our high quality standards.

Packaging and Shipping

Your tubes are carefully packaged to prevent damage during transit. We use protective materials and secure packaging methods to ensure your products arrive in perfect condition. Our logistics team coordinates with reliable carriers to provide timely delivery to destinations worldwide.

Why Choose Us

Located in China's "Titanium Capital," we combine decades of experience with modern manufacturing capabilities. Our founder's 30+ years in rare metals ensures you receive expert guidance and superior products. We've successfully served customers in over 50 countries, building lasting partnerships through quality and reliability.

|

|

|

|

|

|

FAQs

Q: What makes seamless tubes better than welded options?

A: Seamless construction eliminates weak points, provides higher pressure ratings, and offers superior reliability for critical applications.

Q: Can you customize tube dimensions?

A: Yes, we offer custom dimensions within our manufacturing capabilities to meet your specific requirements.

Q: What industries commonly use these products?

A: Aerospace, electronics, chemical processing, medical, and research industries frequently specify our niobium seamless tube products.

Contact Us

Ready to discuss your niobium tube requirements? Our technical team is here to help you select the right solution for your application. Contact us today to learn how our premium niobium seamless tube products can enhance your project's success.

E-mail: info@chdymetal.com

Mob./what'sapp: 86-18049386902

Learn about our latest products and discounts through SMS or email