- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

titanium foil 0.5 mm sheet

2.Grade Gr1 Gr2 Gr5 Gr7 Gr9 Gr12 Gr23

3.Size: T (0.1mm - 10.0mm) * W (10-1000mm) * L as your request

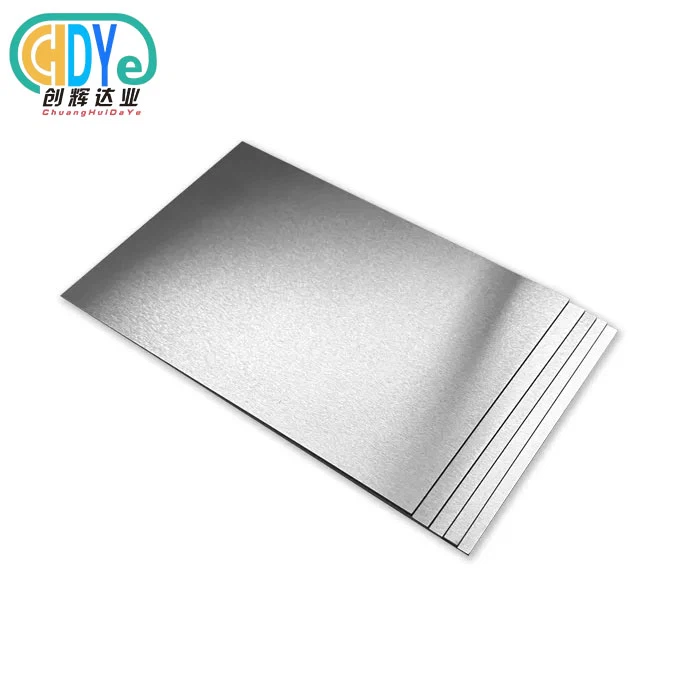

Titanium Foil 0.5 mm Sheet

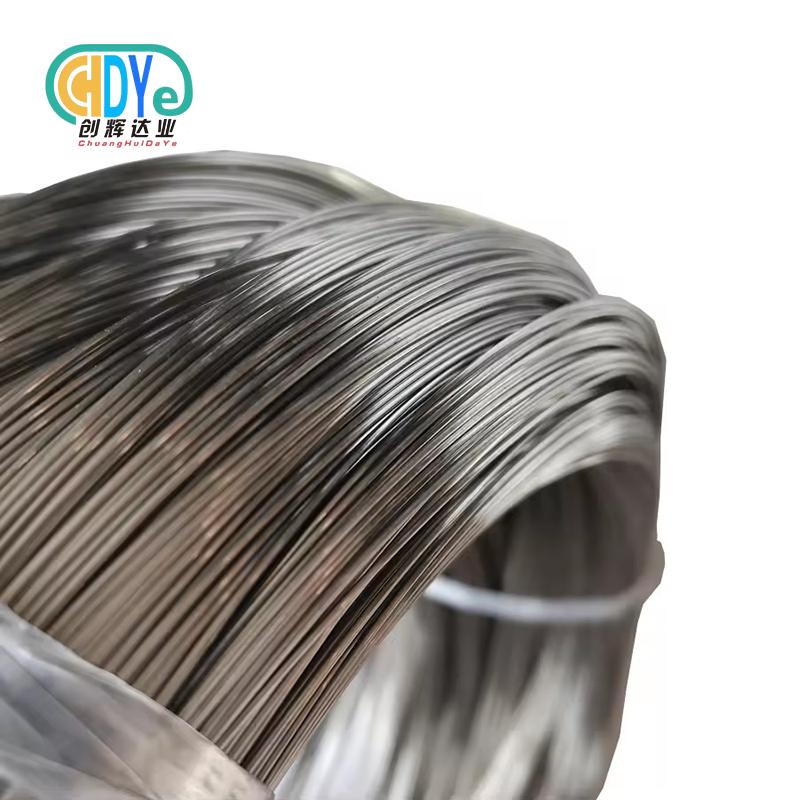

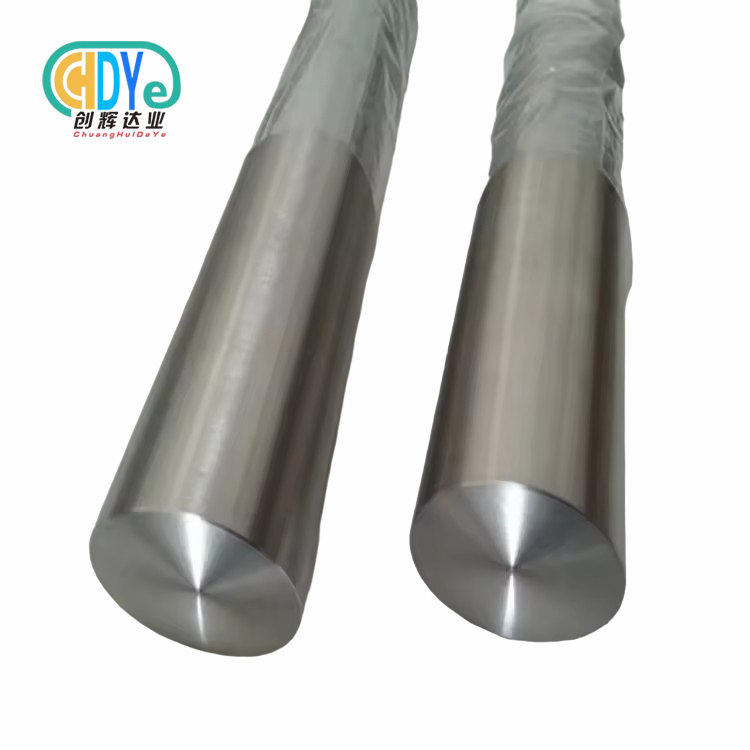

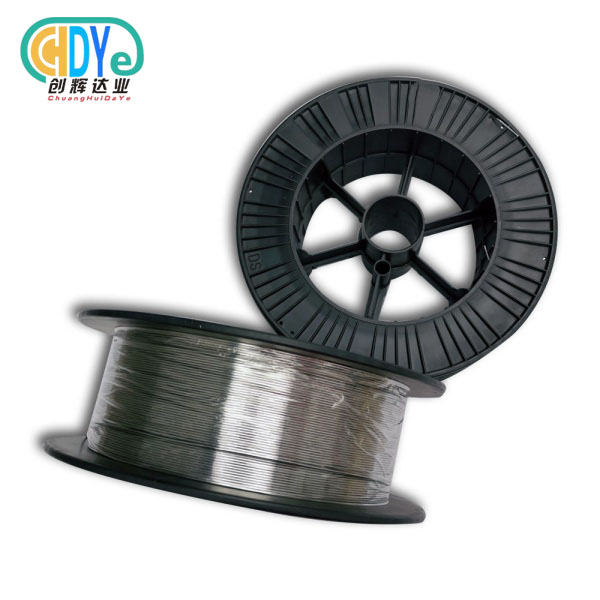

Looking for high-performance titanium foil 0.5 mm sheet for your industrial applications? You've come to the right place. Our precision-manufactured titanium foils offer exceptional strength-to-weight ratio, outstanding corrosion resistance, and reliable performance across demanding environments. With over 30 years of experience in rare metal manufacturing, we deliver quality products that meet international standards. Whether you need materials for aerospace, medical devices, or chemical processing, our titanium solutions provide the durability and precision your projects demand.

Key Features and Benefits

Our titanium foils stand out in the market for several compelling reasons. First, you get exceptional corrosion resistance that outperforms stainless steel in harsh environments. The lightweight nature reduces overall component weight by up to 40% compared to steel alternatives.

You'll also benefit from excellent formability and workability. Our foils maintain structural integrity during complex forming operations. The biocompatible properties make them perfect for medical applications. Plus, the high strength-to-weight ratio ensures optimal performance without unnecessary bulk.

Temperature resistance is another key advantage. These materials perform reliably from cryogenic temperatures up to 400°C. The non-magnetic properties are ideal for sensitive electronic applications.

Technical Specifications

|

Standard |

ASTM / ASME SB265 |

|

Size |

1000 mm x 2000 mm, 1220 mm x 2440 mm, 1220*Length |

|

Thickness |

1mm to 12 mm Thk |

|

Form |

Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, |

|

Finish |

Hot rolled plate (HR), Cold rolled sheet (CR) |

|

Hardness |

Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

| Certificate |

ISO 9001:2015 |

| Condition |

Annealed |

| Surface |

cold rolling bright surface |

|

Packing Detail |

Standard export package: Wooden pallet +paperboard +coil |

|

Delivery time |

1.Usually, within10-15 days after receiving deposit |

Available Grades and Materials

We offer two primary grades to meet your specific requirements. Grade 2 titanium provides excellent corrosion resistance and formability. It's perfect for chemical processing, marine applications, and architectural projects.

Grade 5 (Ti-6Al-4V) delivers superior strength and is ideal for aerospace applications. This alpha-beta alloy offers the best combination of strength, weight savings, and corrosion resistance. It's commonly used in aircraft components, medical implants, and high-performance sporting goods.

Both grades comply with ASTM B265 standards. We can also provide custom compositions based on your specific needs.

Chemical composition

|

Composition (%) |

C |

N |

Fe |

O |

H |

Al |

v |

Ti |

|

GR1 |

≤0.08 |

≤0.03 |

≤0.20 |

≤0.18 |

≤0.015 |

-- |

|

Bal |

|

GR2 |

≤0.08 |

≤0.03 |

≤0.30 |

≤0.25 |

≤0.015 |

--- |

|

Bal |

|

GR5 |

≤0.10 |

≤0.05 |

≤0.30 |

≤0.20 |

≤0.015 |

5.50-6.80 |

3.50-4.50 |

Bal |

Physical properties

|

Grade |

Tensile Strength |

Yield Strength 0.2% Offset |

Elongation |

Bend Test |

|

|

Min |

Min |

Min Max |

|

Under 0.070 in.(1.8mm)in thickness |

|

|

|

KSI |

MPA |

Ksi MPA KSI MPA |

|

|

|

1 |

35 |

240 |

20 138 45 310 |

24 |

1.5T |

|

2 |

50 |

345 |

40 275 65 450 |

20 |

2T |

Manufacturing Process

Our advanced manufacturing process ensures consistent quality and precision. We start with high-purity titanium ingots sourced from certified suppliers. The hot rolling process reduces thickness while maintaining material properties.

Cold rolling follows to achieve the precise 0.5mm thickness you need. Multiple passes ensure uniform thickness across the entire sheet width. Annealing treatments optimize mechanical properties and relieve internal stresses.

Quality control checks occur at every stage. Final inspection includes dimensional verification, surface quality assessment, and mechanical property testing.

|

|

|

|

|

|

|

|

Applications and Industries

The versatility of our titanium foil 0.5 mm sheet makes it suitable for numerous industries. In aerospace, you'll find it in aircraft skin panels, heat shields, and structural components. The medical industry uses it for surgical instruments, implants, and diagnostic equipment.

Chemical processing benefits from its corrosion resistance in reactor vessels and heat exchangers. Marine applications include propeller shafts, hull components, and desalination equipment.

Electronics manufacturers appreciate the non-magnetic properties for sensitive components. Architecture and automotive industries use it for decorative panels and lightweight structural elements.

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain strict dimensional tolerances to ensure your components fit perfectly. Thickness tolerance is ±0.025mm for the 0.5mm specification. Width tolerance varies from ±1mm for narrow strips to ±3mm for full-width sheets.

Length cutting accuracy is ±2mm for standard lengths. Surface finish meets industrial standards with Ra values typically below 1.6 μm. Edge quality is carefully controlled with minimal burr formation.

Product Features in Detail

The microstructure of our titanium foils provides optimal performance characteristics. Grain size is controlled during processing to balance strength and formability. Surface treatment options include pickled, bright annealed, or as-rolled finishes.

Mechanical properties remain consistent across the entire sheet area. We can provide mill test certificates documenting all relevant properties. Special packaging preserves surface quality during shipping and storage.

Quality Assurance and Testing

Every batch undergoes comprehensive testing before shipment. Tensile testing verifies mechanical properties according to international standards. Chemical analysis confirms composition compliance.

Ultrasonic testing detects internal defects. Surface inspection ensures cosmetic quality meets your requirements. We maintain ISO quality management systems and provide full traceability documentation.

Third-party testing is available upon request. All test results are documented and provided with your shipment.

|

|

|

OEM & Customization Services

We understand that standard sizes don't always meet your needs. Our customization services include precision cutting to your exact dimensions. Surface treatments can be modified for specific applications.

Special packaging options protect your materials during transport. We can provide just-in-time delivery to support your production schedules. Technical support helps optimize material selection for your applications.

Packaging and Shipping

Careful packaging protects your titanium foil during transit. Sheets are interleaved with protective paper to prevent surface damage. Moisture barriers protect against corrosion during storage.

We ship worldwide with reliable freight partners. Express shipping options are available for urgent requirements. Tracking information keeps you informed of delivery status.

|

|

|

|

|

|

|

|

|

Why Choose Us

Located in China's "Titanium Capital," we have access to the best raw materials and manufacturing expertise. Our founder's 30+ years of experience ensures deep industry knowledge.

We serve customers in over 50 countries worldwide. Competitive pricing doesn't compromise quality. Customer-focused service means we're always available to help.

Continuous improvement drives our operations. We invest in the latest technology to maintain our competitive edge.

|

|

|

|

|

|

FAQs

Q: What's the minimum order quantity for titanium foil 0.5 mm sheet?

A: We accommodate both small prototype quantities and large production runs. Contact us for specific volume requirements.

Q: Can you provide material certificates?

A: Yes, we provide mill test certificates with every shipment documenting all relevant properties and composition.

Q: What surface finishes are available?

A: We offer pickled, bright annealed, and as-rolled finishes. Special surface treatments are available upon request.

Q: How do you ensure dimensional accuracy?

A: Advanced measuring equipment and strict quality control procedures ensure all dimensions meet specified tolerances.

Contact Us

Ready to discuss your titanium foil requirements? Our technical team is standing by to help you select the right materials for your application.

Email us at info@chdymetal.com for quotes, technical information, or any questions about our products. We typically respond within 24 hours with detailed information tailored to your needs.

Let us be your trusted partner for high-quality titanium solutions.

Learn about our latest products and discounts through SMS or email