- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

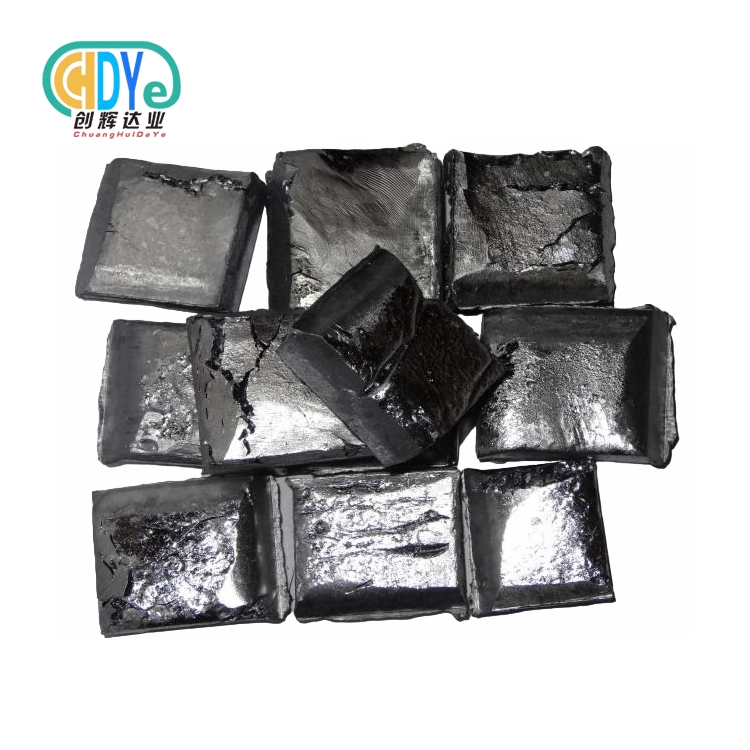

smelting niobium block

2.Specifications: 30*50mm,120 gram each piece, irregular shape Or customized

Product Introduction

Welcome to Shaanxi Chuanghui Daye Metal Material Co., Ltd., where we specialize in premium quality smelting niobium block solutions. Our niobium blocks are engineered for excellence in vacuum induction melting applications. With 99.8% purity and exceptional metallurgical properties, these blocks serve as the ideal feedstock for superalloy production and advanced manufacturing processes. Each smelting niobium block features controlled oxygen content below 300 ppm and optimal density characteristics that ensure consistent melting performance across diverse industrial applications.

Key Features and Benefits

- Superior Purity: 99.9% minimum purity for reliable melting results

- Optimal Block Size: 25-120mm dimensions perfect for feedstock applications

- High Density: ≥99.7% theoretical density ensures uniform melting

- Low Impurities: Controlled oxygen, hydrogen, and gas content

- Temperature Resistance: 2470°C melting point supports demanding processes

- Versatile Applications: Suitable for superalloys, superconductors, and specialty metals

Chemical composition

|

Grade |

O |

H |

C |

N |

Fe |

Si |

W |

Al |

|

Nb0 |

0.04 |

0.002 |

0.01 |

0.03 |

0.01 |

0.03 |

0.005 |

0.005 |

|

Nb1 |

0.04 |

0.002 |

0.01 |

0.03 |

0.01 |

0.03 |

0.005 |

0.15 |

|

|

Mo |

Ti |

Cu |

Zr |

Ta |

Ni |

Cr |

- |

|

Nb0 |

0.005 |

0.005 |

0.003 |

0.005 |

0.1 |

0.005 |

0.005 |

- |

|

Nb1 |

0.005 |

0.005 |

0.003 |

0.005 |

0.1 |

0.005 |

0.005 |

- |

Available Grades and Materials

We offer two primary grades to meet your specific requirements:

Grade Nb0: Ultra-high purity grade for critical applications requiring maximum performance

Grade Nb1: High-quality standard grade suitable for most industrial applications

Both grades maintain excellent surface quality with characteristic silver-grey appearance and zero oxidation or contamination.

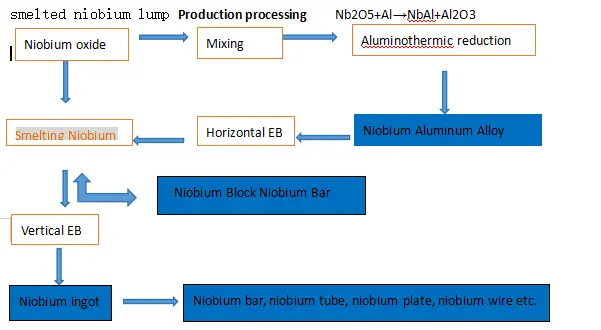

Manufacturing Process

Our production process ensures consistent quality through controlled manufacturing steps. We utilize advanced vacuum melting techniques to achieve optimal purity levels. Each batch undergoes rigorous quality testing to verify chemical composition and physical properties. The manufacturing environment maintains strict contamination control to preserve the integrity of every niobium block.

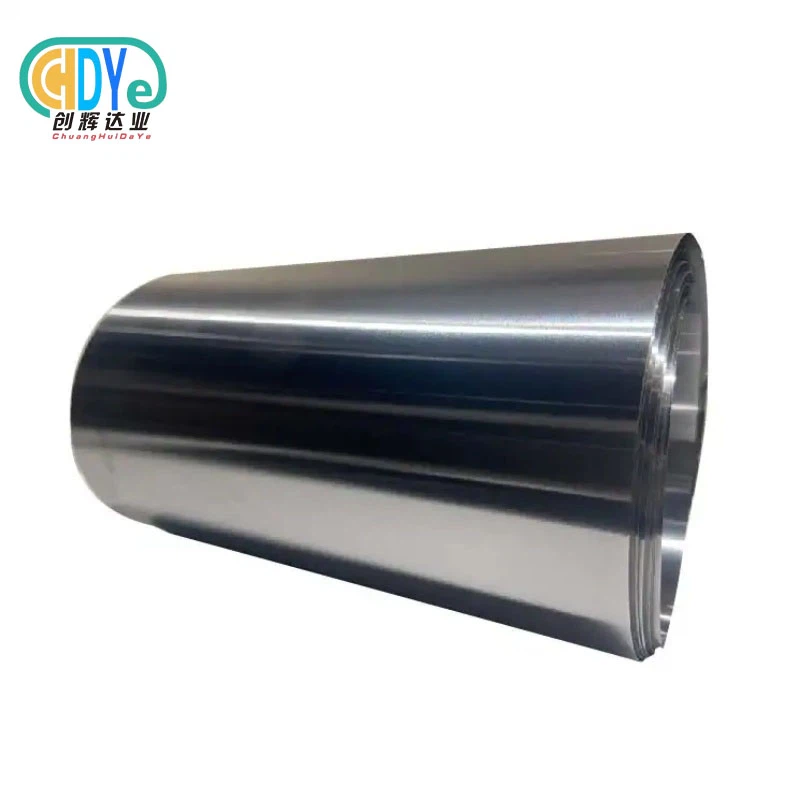

Applications and Industries

Your smelting niobium block finds applications across multiple high-tech industries:

- Superalloy Production: Essential additive for aerospace and gas turbine components

- Superconductor Manufacturing: Critical material for advanced electronic applications

- Steel Industry: Alloying element for high-strength steel production

- Electronic Components: Base material for specialized electronic devices

- Medical Implants: Biocompatible applications in medical device manufacturing

- Chemical Processing: Corrosion-resistant equipment manufacturing

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

Standard dimensions include 30×50mm blocks weighing approximately 120 grams each. We accommodate irregular shapes based on your specific requirements. Custom sizing options are available to match your exact application needs. All products maintain tight dimensional tolerances to ensure consistent performance in your processes.

Product Features in Detail

The surface quality of our niobium blocks meets stringent industry standards. Each block exhibits uniform silver-grey coloration without oxidation marks or surface contamination. The controlled hardness range of 100-125 HV makes these blocks suitable for subsequent forging operations. Low gas content prevents brittleness issues during high-temperature processing.

Quality Assurance and Testing

Every smelting niobium block undergoes comprehensive testing protocols. We verify chemical composition through spectral analysis and measure physical properties including density and hardness. Gas content analysis ensures compliance with specified limits. Each shipment includes detailed test certificates documenting product quality parameters.

OEM & Customization Services

We understand that your applications may require specific configurations. Our experienced team works closely with you to develop customized solutions. Whether you need modified dimensions, special purity levels, or unique packaging requirements, we adapt our products to meet your exact specifications.

Packaging and Shipping

Products are carefully packaged in protective drums containing 50kg per drum. This packaging method prevents contamination during transport and storage. We arrange reliable shipping to over 50 countries worldwide, ensuring your materials arrive safely and on schedule.

Why Choose Us

Located in Baoji, China's "Titanium Capital," we leverage over 30 years of rare metal industry experience. Our commitment to quality assurance and customer satisfaction drives everything we do. You benefit from competitive pricing, reliable delivery schedules, and responsive customer service. We've built our reputation on trust, reliability, and continuous improvement.

|

|

|

FAQs

Q: What makes your niobium blocks suitable for vacuum melting?

A: Our blocks feature controlled gas content and high density, ensuring clean melting without contamination issues.

Q: Can you provide custom block sizes?

A: Yes, we manufacture blocks according to your specific dimensional requirements while maintaining quality standards.

Q: How do you ensure consistent purity levels?

A: We employ advanced vacuum melting techniques and comprehensive testing protocols to guarantee specified purity levels.

Contact Us

Ready to enhance your manufacturing processes with premium smelting niobium block solutions? Our technical team stands ready to assist with product selection and application guidance. Contact us today at info@chdymetal.com to discuss your specific requirements. We look forward to becoming your trusted partner for high-quality niobium products and exceptional service.

Learn about our latest products and discounts through SMS or email

_1760924447399.jpg)