- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

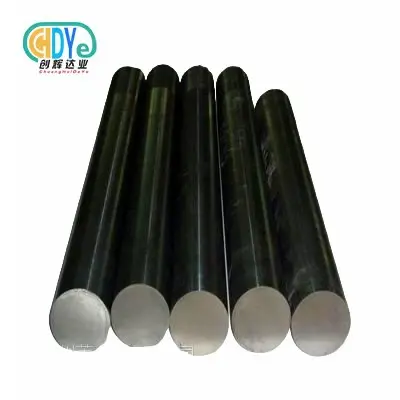

Pure-molybdenum-bar

Product Introduction

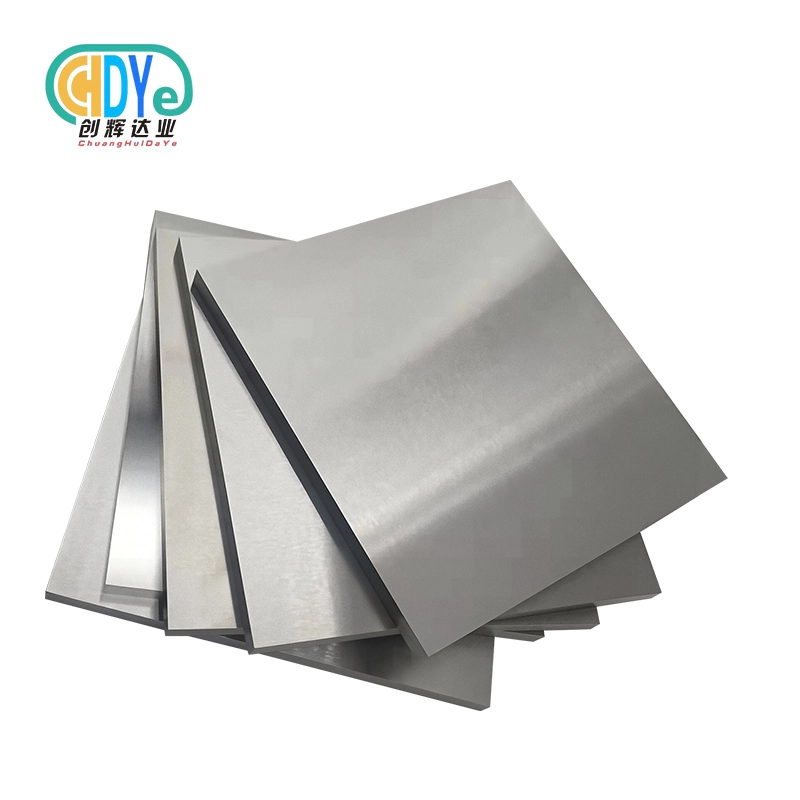

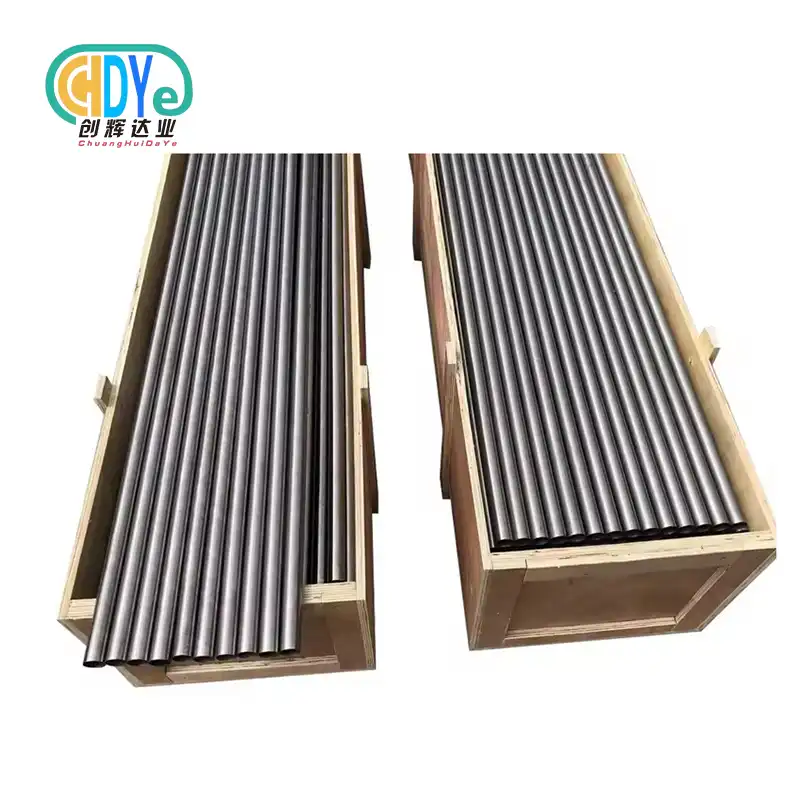

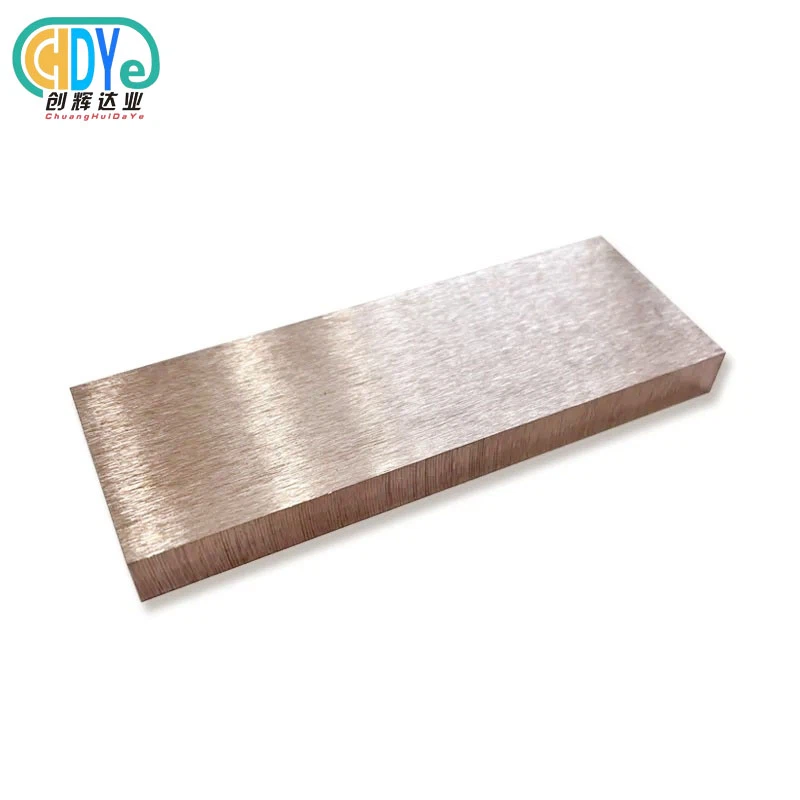

Shaanxi Chuanghui Daye Metal Material Co., Ltd. proudly offers the Pure-Molybdenum-Bar, a high-performance product known for its excellent thermal conductivity, outstanding corrosion resistance, and remarkable high-temperature strength. Manufactured from ultra-high purity molybdenum, each Pure Molybdenum Rod undergoes advanced electron beam melting, forging, and precision machining to ensure uniform density and fine grain structure. Our Pure Molybdenum Rod is suitable for industries requiring extreme durability and stability under harsh conditions. We provide both standard and custom sizes to meet diverse industrial needs.

Pure molybdenum bar is a high-purity molybdenum product, mainly composed of molybdenum (Mo), with a purity usually exceeding 99.95%. Pure molybdenum rods have high melting points, good thermal conductivity, and low thermal expansion properties, exhibiting excellent oxidation resistance and strength at high temperatures.

Sizes and Standard

Our pure molybdenum bar size range in diameter from 3-150mm*L, customized

Molybdenum bar order ships with standard ASTM B387.

Features

High melting point: The melting point of pure molybdenum is 2623 ℃, which makes it perform well in high temperature environments.

Good thermal conductivity: Pure molybdenum rods have excellent thermal conductivity and are suitable for applications that require good heat dissipation.

Low thermal expansion performance: When the temperature changes, the size of pure molybdenum rods changes relatively little, making them suitable for use in precision instruments and equipment.

Antioxidant: At high temperatures, pure molybdenum rods can resist oxidation and extend their service life.

Quality Requirements:

Surface of forged Moly bar can be allowed to have oxidation film and slight traces of forging;

Surface of grinding Moly bar shows metallic luster, no significant oxidation phenomenon;

Both the surface of Moly bar without layering, crack, burr, longitudinal crack and other defects;

Application

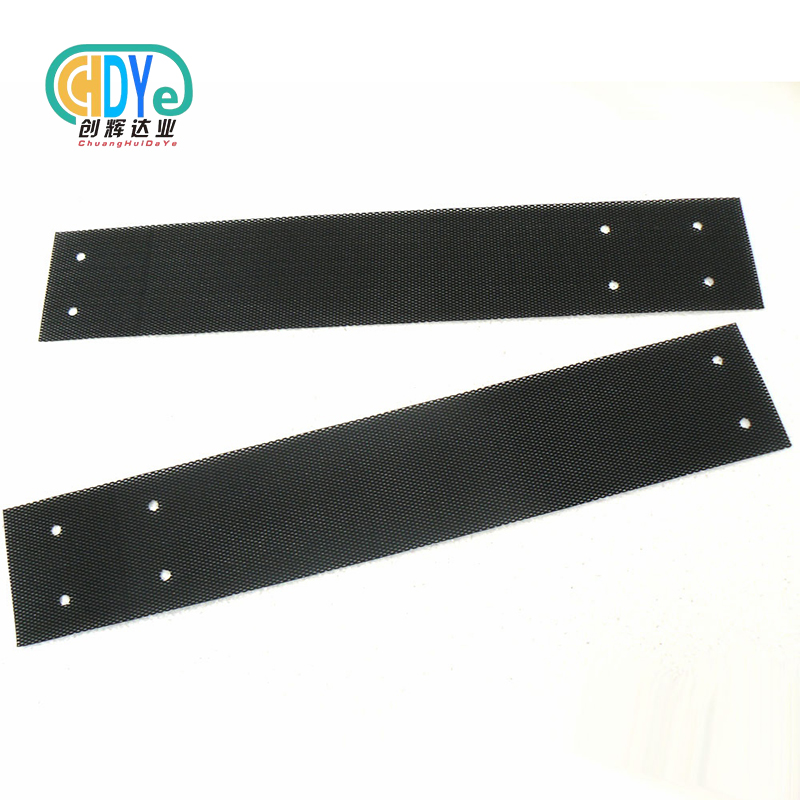

The Pure-Molybdenum-Bar is widely used in industries that demand high performance and reliability:

- Metallurgy: Furnace components, heating elements, and high-temperature structural parts.

- Electronics & Semiconductors: Electrodes, supports, and vacuum device components.

- Aerospace & Defense: Thermal shielding, propulsion systems, and high-stress components.

- Energy & Chemical Processing: Corrosion-resistant parts in reactors and high-pressure vessels.

- Medical Equipment: X-ray tubes, diagnostic devices, and high-temperature medical instruments.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

The production process of Pure-Molybdenum-Bar follows strict quality and safety standards:

- Raw Material Selection: High-purity molybdenum powder for optimal performance.

- Pressing & Sintering: Isostatic pressing and sintering under hydrogen protection.

- Forging & Rolling: Multi-stage forging and rolling to achieve uniform structure.

- Machining: Precision turning, grinding, and finishing to meet tight tolerances.

- Inspection & Packaging: Dimensional, surface, and mechanical property checks before shipment.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality is central to our production philosophy. Each Pure-Molybdenum-Bar undergoes comprehensive inspections:

- Chemical composition verification

- Ultrasonic and dimensional inspection

- Mechanical property evaluation (tensile strength, hardness, density)

- Surface roughness and grain size analysis

- Final audit and certification

Our ISO 9001:2015 certified system guarantees consistency and reliability for every order.

R&D and Customization

Our R&D team continuously develops improved molybdenum products. Customization services for Pure Molybdenum Rod include:

- Tailored dimensions and tolerances

- Special surface treatments (polished, ground, or centerless)

- Alloy modifications for enhanced high-temperature strength

- Prototype and small-batch production for testing and development

This ensures our clients receive high-performance solutions tailored to their specific industrial needs.

Packaging & Global Logistics

To maintain product integrity, Pure Molybdenum Rod is packaged and shipped with care:

- Packaging: Vacuum-sealed or anti-rust film with foam protection in export-standard wooden boxes.

- Marking: Clear labeling with product specifications, grade, and batch number.

- Transportation: Safe and reliable air, sea, and land logistics to over 50 countries worldwide.

Every shipment is designed for fast, secure delivery while preserving product quality.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye provides OEM and ODM services for Pure Molybdenum Rod:

- Custom sizes, grades, and drawings

- Engineering and material selection guidance

- Flexible production from prototypes to bulk orders

- Full after-sales support and technical consultation

Our goal is to provide high-quality, cost-effective molybdenum solutions to meet global customer demands.

Inspection Process

Each Pure-Molybdenum-Bar goes through a rigorous inspection process:

- Incoming Material Testing – Verify purity and composition.

- Dimensional Control – Ensure precision at every machining stage.

- Surface Examination – Detect micro-defects using advanced instruments.

- Mechanical Testing – Confirm tensile, hardness, and density specifications.

- Final Audit – Certified quality assurance report prior to packaging and shipping.

Why Choose Us

- Over 30 years of experience in rare metal production

- Advanced melting, forging, and machining facilities

- ISO 9001:2015 certified quality management system

- Strong R&D capabilities and customized solutions

- Fast 7-day delivery and global logistics support

- Trusted supplier in more than 50 international markets

Our commitment to quality and innovation makes us a reliable partner for Pure-Molybdenum-Bar supply worldwide.

|

|

|

|

|

|

FAQs

Q1: What purity level is available for your molybdenum bars?

A1: Our Pure Molybdenum Rod has a purity of ≥99.95%, compliant with ASTM B387 standards.

Q2: Can I order custom sizes or surface finishes?

A2: Yes, we provide customized dimensions and treatments such as polished, ground, or centerless finishing.

Q3: Which industries use your molybdenum bars most frequently?

A3: They are widely used in metallurgy, aerospace, electronics, vacuum furnaces, and chemical processing.

Q4: How is the quality of Pure Molybdenum Rod ensured?

A4: Each bar undergoes chemical analysis, ultrasonic testing, mechanical testing, and final certification.

Q5: What is the typical delivery time for standard and custom orders?

A5: Standard sizes can be shipped within 7 days; custom orders depend on specifications and quantity.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email