- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

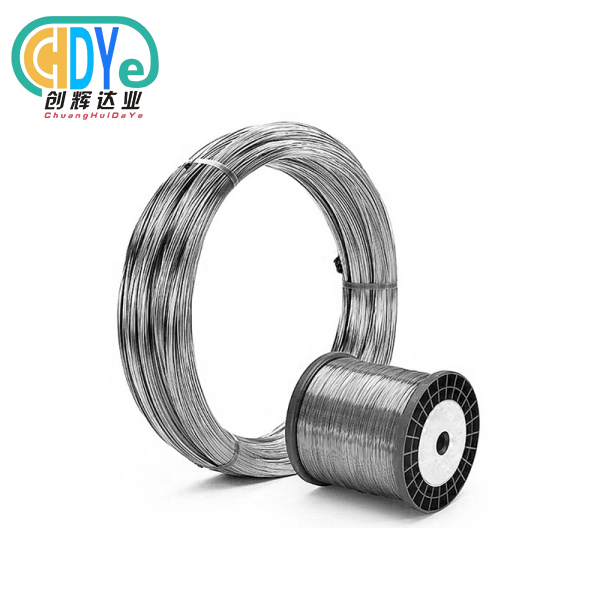

titanium coil wire

2. Diameter: 0.1–5 mm

3. Tensile strength: 345–895 MPa

4. Density: 4.43–4.51 g/cm³

5. Corrosion resistant: Excellent

6. Shape: Coiled

7. Applications: Jewelry, industrial

Product Production

Looking for high-quality titanium coil wire for your industrial or specialty applications? You've come to the right place. At Shaanxi Chuanghui Daye Metal Material Co., Ltd., we specialize in manufacturing premium titanium coil wire that meets the demanding requirements of modern industries. Our expertly crafted coil wire delivers exceptional strength, corrosion resistance, and reliability. Whether you need titanium wire for aerospace, medical devices, or industrial applications, our products offer the perfect combination of performance and durability to exceed your expectations.

Key Features and Benefits

Our premium coil wire stands out in the market due to its exceptional properties. The superior strength-to-weight ratio makes it ideal for weight-sensitive applications. You'll appreciate the outstanding corrosion resistance that ensures long-lasting performance even in harsh environments. The excellent biocompatibility makes it perfect for medical applications, while the high-temperature stability provides reliable performance under extreme conditions.

Technical Specifications

| Property | Specification |

|---|---|

| Alloy Grades | Ti Gr2, Ti Gr5 |

| Diameter Range | 0.1 – 5 mm |

| Tensile Strength | 345 – 895 MPa |

| Density | 4.43 – 4.51 g/cm³ |

| Shape | Coiled |

| Corrosion Resistance | Excellent |

| Temperature Range | -200°C to 600°C |

| Elongation | 15-25% |

| Technique | Hot Rolled, Cold Rolling, Annealed |

| Surface | Black, Pickled, Polished ( For Dia. >1mm ) |

| Packing terms | Internal foam soft packing External export wooden box |

|

Payments terms |

30%TT in advance,70%balance before shipment |

Chemical composition

|

|

N |

C |

H |

Fe |

O |

Al |

V |

Pa |

Mo |

Ni |

Ti |

|

Gr 1 |

0.03 |

0.08 |

0.015 |

0.20 |

0.18 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 2 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 3 |

0.05 |

0.08 |

0.015 |

0.30 |

0.35 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 4 |

0.05 |

0.08 |

0.015 |

0.50 |

0.40 |

/ |

/ |

/ |

/ |

/ |

|

|

Gr 5 |

0.05 |

0.08 |

0.015 |

0.40 |

0.20 |

5.5~6.75 |

3.5~4.5 |

/ |

/ |

/ |

bal |

|

Gr 7 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

0.12~0.25 |

/ |

/ |

bal |

|

Gr 9 |

0.03 |

0.08 |

0.015 |

0.25 |

0.15 |

2.5~3.5 |

2.0~3.0 |

/ |

/ |

/ |

bal |

Available Grades and Materials

We offer premium coil wire in various grades to meet your specific requirements. Grade 2 titanium provides excellent corrosion resistance and formability, making it perfect for general industrial applications. Grade 5 (Ti-6Al-4V) offers enhanced strength and high-temperature performance, ideal for aerospace and demanding industrial uses.

Manufacturing Process

Our advanced manufacturing process ensures consistent quality and performance. We start with high-purity titanium raw materials, followed by precise cold drawing or hot rolling techniques. Each coil undergoes strict quality control measures, including dimensional verification and surface inspection. The final product receives appropriate heat treatment to achieve optimal mechanical properties.

|

|

|

|

|

|

|

|

Applications and Industries

The versatility of our titanium coil wire makes it suitable for numerous applications. In the aerospace industry, it's used for aircraft components and engine parts. Medical applications include surgical instruments and implants. Industrial uses encompass chemical processing equipment, marine hardware, and automotive components. The jewelry industry also values it for its hypoallergenic properties and attractive appearance.

Be used in a wide range of industries.

Metallurgy and Special Steel

Electronics and Semiconductors

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain tight tolerances to ensure consistent performance. Diameter tolerances are typically ±0.01mm for precision applications. Standard coil packaging comes in various sizes from 1kg to 50kg spools. Custom dimensions and packaging are available upon request to meet your specific requirements.

Product Features in Detail

Our coil wire features a smooth, clean surface finish that's free from defects. The uniform chemical composition ensures consistent mechanical properties throughout the entire length. You'll find excellent workability that allows for easy forming and shaping. The material exhibits superior fatigue resistance, making it ideal for dynamic applications.

Quality Assurance and Testing

Every batch of our titanium coil wire undergoes comprehensive testing. We perform chemical composition analysis, tensile testing, and dimensional verification. Surface quality inspection ensures defect-free products. Our quality management system ensures traceability and consistent performance across all shipments.

|

|

|

OEM & Customization Services

We understand that different applications require specific solutions. Our experienced team works closely with you to develop customized wire specifications. Whether you need special alloy compositions, unique dimensions, or specific packaging requirements, we can accommodate your needs. Our flexibility in production allows for both small prototype quantities and large-scale manufacturing.

Packaging and Shipping

Your coil wire is carefully packaged to prevent damage during transportation. We use moisture-proof packaging with proper cushioning. Standard packaging includes plastic spools or wooden reels depending on wire diameter and length. International shipping is available with proper documentation and certification.

|

|

|

|

|

|

|

|

|

Why Choose Us

With over 30 years of experience in rare metals, we bring unmatched expertise to every project. Located in China's "Titanium Capital," we have access to the finest raw materials and manufacturing facilities. Our commitment to quality and customer satisfaction has earned us customers in over 50 countries worldwide. We provide competitive pricing, reliable delivery, and exceptional technical support.

|

|

|

|

|

|

FAQs

Q: What's the minimum order quantity for titanium coil wire?

A: Our minimum order quantity varies by diameter and grade, typically starting from 10kg.

Q: Can you provide material certificates?

A: Yes, we provide complete material certificates including chemical composition and mechanical properties.

Q: What's your typical delivery time?

A: Standard products ship within 1-2weeks, while custom specifications may require 2-3weeks.

Q: Do you offer technical support?

A: Absolutely! Our experienced engineers provide comprehensive technical support throughout your project.

Contact Us

Ready to discuss your titanium coil wire requirements? Our expert team is here to help you find the perfect solution for your application. Contact us today for pricing, technical specifications, or custom requirements.

Email: info@chdymetal.com

Mob.: 86-18049386902

Let us be your trusted partner for premium titanium wire solutions. Experience the difference that quality materials and exceptional service can make for your next project.

Learn about our latest products and discounts through SMS or email