- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

niobium sputtering target

Density ≥8.5 g/cm³ ensures stable sputtering output

Grain size ≤40 μm improves coating uniformity

Thickness tolerance ±0.02 mm for precise deposition

Oxygen content ≤120 ppm enhances clean film quality

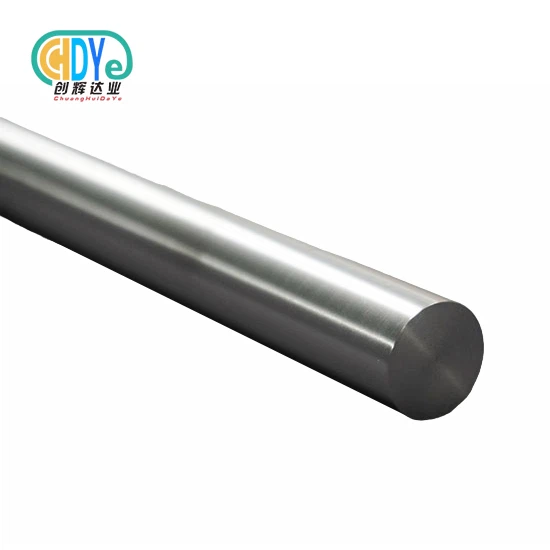

Diameter 100–400 mm fits industrial sputtering equipment

Surface roughness Ra ≤0.8 μm enhances adhesion

RRR ≥35 supports high electrical conductivity

Looking for premium niobium sputtering target materials for your thin film deposition needs? You've come to the right place. At Shaanxi Chuanghui Daye Metal Material Co., Ltd., we specialize in manufacturing high-quality niobium targets with 99.95% purity, specifically designed for semiconductor, electronics, and advanced coating applications. Our expertly crafted targets deliver consistent performance and superior film quality for your critical sputtering processes.

Key Features and Benefits

Our advanced niobium targets offer exceptional value for your manufacturing operations:

- Ultra-High Purity: 99.95% purity ensures clean, contamination-free thin films

- Superior Density: ≥8.5 g/cm³ provides stable sputtering performance

- Precise Tolerances: ±0.02 mm thickness control for consistent results

- Fine Grain Structure: ≤40 μm grain size improves coating uniformity

- Low Oxygen Content: ≤120 ppm enhances film quality and properties

- Excellent Conductivity: RRR ≥35 supports optimal electrical performance

Technical Specifications

| Parameter | Specification |

|---|---|

| Purity | ≥99.95% |

| Density | ≥8.5 g/cm³ |

| Grain Size | ≤40 μm |

| Thickness Tolerance | ±0.02 mm |

| Oxygen Content | ≤120 ppm |

| Surface Roughness | Ra ≤0.8 μm |

| RRR Value | ≥35 |

| Melting Point | 2477°C |

| Certificate | ISO9001: 2015 |

| Standard | ASTM B 392 |

| Surface | cold rolled surface / Machined surface |

| Delivery time | normal 7-15 days |

| payment term | 30%TT in advance, 70% balance before shipment |

Available Grades and Materials

| Grade | Standard | Diameter Range | Thickness Range |

|---|---|---|---|

| R04200 | ASTM B 392 | 5-400 mm | 0.1 mm minimum |

| R04210 | ASTM B 392 | 5-400 mm | 0.1 mm minimum |

Chemical composition

|

Material |

Main elements(%) |

Impurities (Maximum %) |

||||||||||

|

Nb |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Ta |

O |

C |

H |

N |

|

|

RO4200 |

Remainder |

0.004 |

0.004 |

0.002 |

0.005 |

0.005 |

0.002 |

0.07 |

0.015 |

0.0040 |

0.0015 |

0.003 |

|

RO4210 |

Remainder |

0.01 |

0.01 |

0.005 |

0.02 |

0.01 |

0.004 |

0.10 |

0.02 |

0.01 |

0.0015 |

0.01 |

Manufacturing Process

We employ advanced manufacturing techniques to ensure optimal target performance:

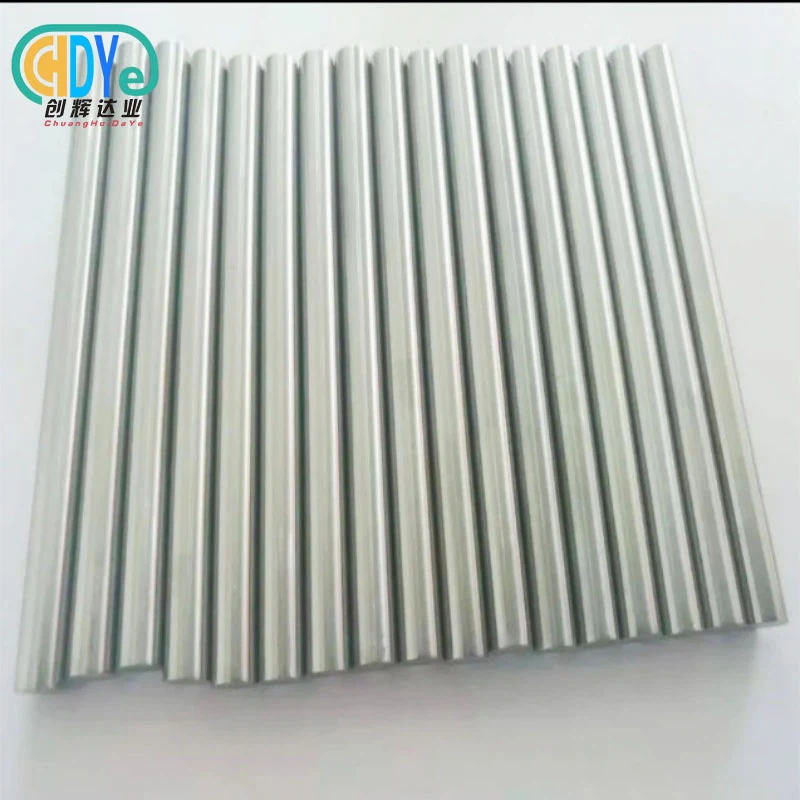

- Cold Rolling Process: Creates uniform grain structure and surface finish

- Precision Machining: Achieves exact dimensional specifications

- Quality Heat Treatment: Optimizes mechanical properties

- Advanced Purification: Removes impurities for enhanced purity levels

|

|

|

|

|

|

|

|

Applications and Industries

Our niobium sputtering target serves diverse industrial applications:

Semiconductor Industry: Essential for chip manufacturing and electronic component production through physical vapor deposition processes.

Electronics Manufacturing: Perfect for LCD displays, transparent electrode layers, and conductive thin films.

Energy Sector: Ideal for solar panel production and photovoltaic cell manufacturing.

Medical Devices: Suitable for biocompatible coatings and dental implant applications.

Research & Development: Supports advanced materials research, superconductor development, and catalyst preparation.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

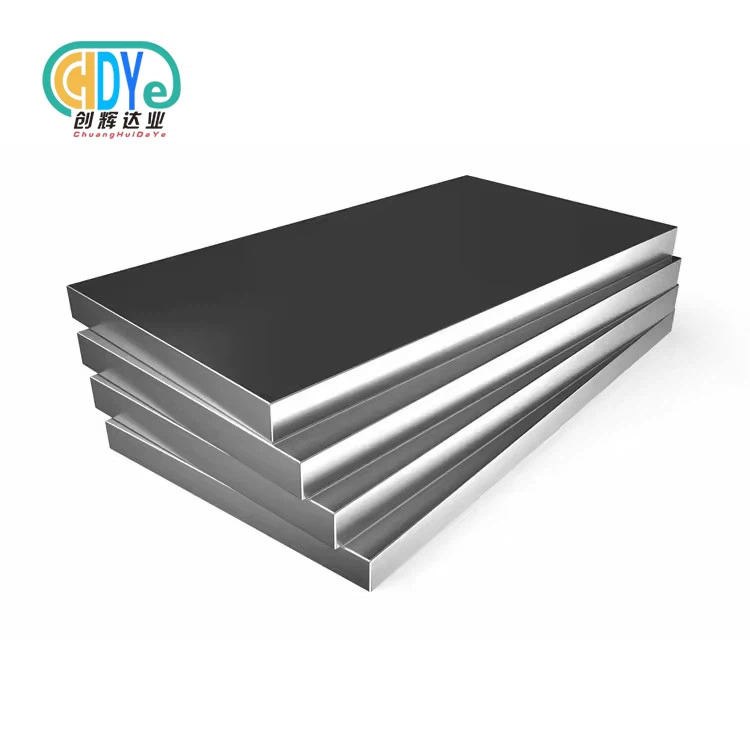

We offer flexible sizing options to meet your specific requirements:

- Diameter: 5 mm to 400 mm (custom sizes available)

- Thickness: 0.1 mm minimum

- Surface Options: Cold rolled or machined finish

- Custom Shapes: Rectangular, square, and specialty configurations

Quality Assurance and Testing

Every target undergoes rigorous quality control:

- Chemical composition analysis

- Density and porosity testing

- Surface roughness measurement

- Dimensional inspection

- Electrical conductivity verification

- Microstructure examination

OEM & Customization Services

We understand that every application has unique requirements. Our engineering team works closely with you to develop customized solutions, including:

- Specialty alloy compositions

- Custom dimensions and shapes

- Specific surface treatments

- Bonding and backing services

- Performance optimization consulting

Packaging and Shipping

Your niobium sputtering target products are carefully packaged to ensure safe delivery:

- Protective foam packaging prevents damage

- Vacuum-sealed options for sensitive applications

- International shipping to over 50 countries

- Comprehensive documentation and certificates

- Expedited delivery options available

Why Choose Us

With over 30 years of rare metal industry experience, we deliver exceptional value:

- Proven Expertise: Decades of specialized knowledge in niobium processing

- Global Reach: Successfully serving customers across 50+ countries

- Quality Focus: Rigorous standards ensure consistent product excellence

- Competitive Pricing: Direct manufacturer pricing with no middleman markup

- Customer Service: Dedicated support throughout your entire project lifecycle

|

|

|

|

|

|

FAQs

Q: What purity levels are available?

A: We provide 99.95% purity as standard, with higher purities available upon request.

Q: Can you provide custom dimensions?

A: Yes, we manufacture targets to your exact specifications within our capability range.

Q: What's the typical lead time?

A: Standard products ship within 1-2 weeks, while custom orders may require 2-3 weeks.

Q: Do you provide technical support?

A: Absolutely! Our experienced engineers offer comprehensive application support.

Contact Us

Ready to enhance your thin film deposition processes? Our team is here to help you select the perfect solution for your application.

Email: info@chdymetal.com

Contact us today for detailed specifications, custom quotes, or technical consultations. We're committed to providing you with the highest quality materials and exceptional service for all your sputtering needs.

Learn about our latest products and discounts through SMS or email