- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

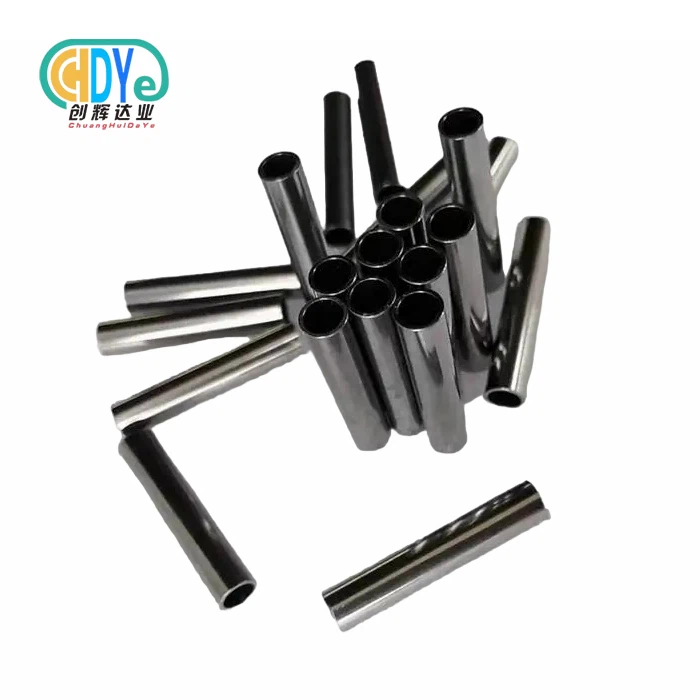

Tantalum Seamless Tube

Product Introduction

Tantalum seamless tube is largely applied to produce tantalum response vessel, tantalum heat exchangers(shell & tube heat exchanger), tantalum pipe line(piping or channel), tantalum condenser, tantalum agitator, tantalum cooler, tantalum boiler, tantalum bayonet heater, tantalum spiral (helical) coil, U-tube heat exchanger or "U" tube bundle heat exchanger during the substance sector for condensing, re-boiling, preheating and cooling of nitric acid, sulfuric acid, hydrochloric acid, formic acid and combinations of those acids with a great deal of other chemicals.

Tantalum seamless pipe can be applied in fluid material tanks along with other glass-lined containers, tantalum thermo few and tantalum thermocouple safeguard sheaths, tantalum thermo well, tantalum emitter, tantalum sleeve, tantalum plasma spray focus on and tantalum tubular sputtering target.

Tantalum seamless tube mechanical property

|

Mechanical Property |

Grade |

Tensile strength min |

Yield strength min, |

Elongation min,% |

|

Pure Ta(R05200 R05400) |

30000(207) |

20000(138) |

20 |

|

|

Ta-10W(R05255) |

70000(482) |

60000(414) |

15 |

|

|

Ta-2.5W(R05252) |

40000(276) |

30000(207) |

20 |

|

|

Ta-40Nb(R05240) |

35000(241) |

20000(138) |

25 |

Advantages and disadvantages of tantalum seamless pipes and welded pipes:

|

|

Advantage |

Disadvantage |

illustrate |

|

Welded tube |

1: Uniform wall thickness and good inner surface quality 2: High production efficiency. Low cost 3: Easy to produce large diameter pipes 4: Short production cycle 5: Easy to control product quality |

1: Poor flexibility, not suitable for producing products with many specifications and small batches 2: The weld is often the weak link 3: It is difficult to clean the weld 4: The ovality is not easy to control 5: High requirements for the dimensional accuracy of the strip used |

Generally suitable for producing large batches of products. |

|

Seamless tube |

1: Can produce small-sized pipes and capillary pipes 2: Good flexibility, suitable for producing small batches and multiple specifications of products. 3: Uniform performance of each part of the pipe |

1: The uniformity of wall thickness is difficult to control 2: The production cycle is long and the yield rate is low 3: The equipment is complex and the investment is large 4: It is difficult to produce large diameter pipes |

Generally suitable for producing products with small batches and large specifications |

Company profile

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is located in Baoji High-tech Development Zone, Shaanxi Province, known as China's "Titanium Capital", with convenient transportation. The founder of the company has more than 30 years experience in the rare metal industry, with rich experience and strong professional ability. He serves the majority of users wholeheartedly and strives to provide users with satisfactory products.

Our main products are: titanium, tantalum, niobium, tungsten, molybdenum, and other non-ferrous and rare metal alloy products, products are widely used in metallurgy, electronics, medical and special steel fields. The company focus on quality assurance, customer first. Our company products successfully applied in the United States, Germany, South Korea, Singapore and other more than 50 countries and regions of the world.

We provide to our customers a competitive cost, on-time delivery, customer focused service, trust, reliability, honesty and continuous improvement. Please do not hesitate to contact us if you plan to work with a strong, reliable and a competitive partner.

Application Advantages

Tantalum seamless tubes are highly valued for their superior corrosion resistance, high melting point, and mechanical durability. They are ideal for use in extreme chemical, thermal, and vacuum environments, where conventional materials cannot perform reliably.

Key Application Advantages:

- Exceptional Corrosion Resistance: Resistant to nearly all acids, including hydrochloric acid, nitric acid, and sulfuric acid, even at high concentrations.

- High-Temperature Stability: Performs continuously up to 3000°C in vacuum or inert gas conditions.

- Excellent Formability: Superior ductility and toughness allow deep drawing and complex shaping.

- Non-reactive Surface: Chemically inert and biocompatible—suitable for medical and analytical instruments.

- Long Service Life: Outstanding wear resistance and oxidation resistance minimize maintenance costs.

Typical Applications:

- Chemical process equipment and heat exchangers

- Cathode protection and acid-resistant tubing systems

- Semiconductor manufacturing and vacuum furnace components

- Medical and laboratory instruments

- Aerospace propulsion and high-temperature reactor assemblies

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

At Shaanxi Chuanghui Daye Metal Material Co., Ltd., tantalum seamless tubes are manufactured through precision-controlled processes ensuring high purity, dimensional accuracy, and consistent mechanical performance.

Process Flow:

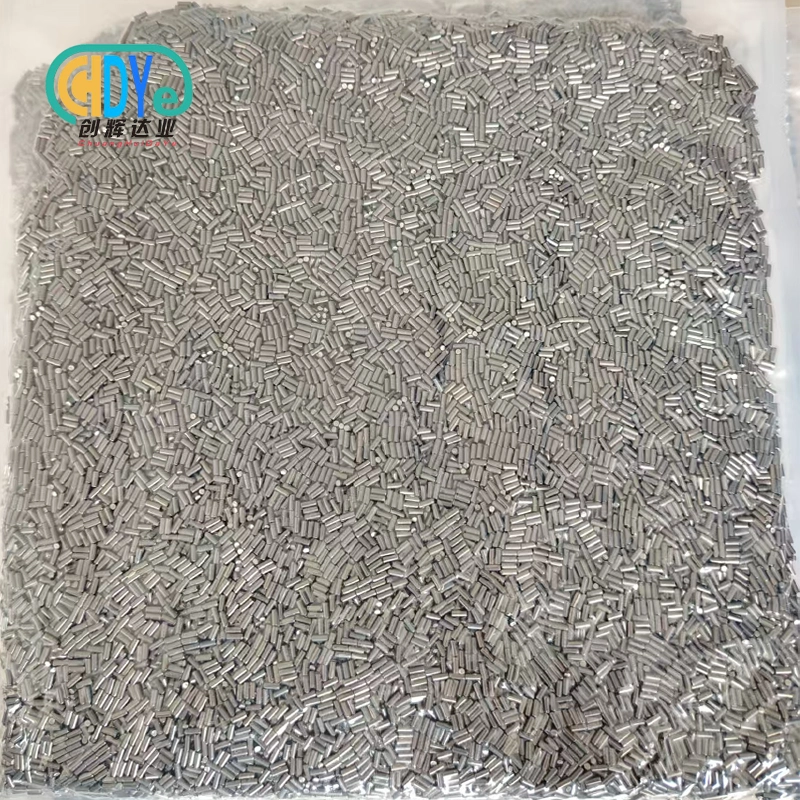

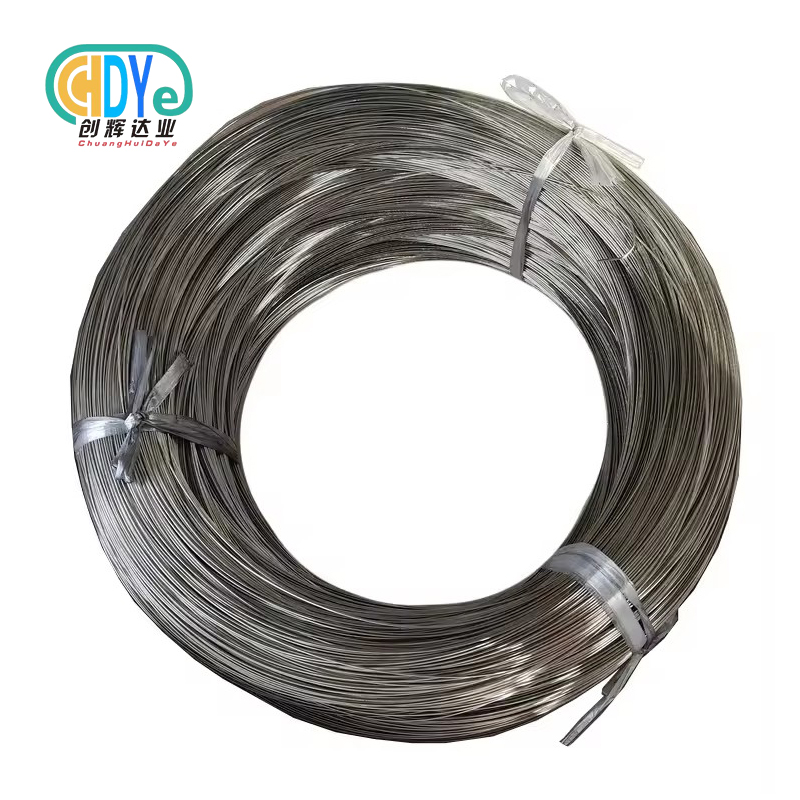

- Raw Material Selection: 99.95%–99.99% high-purity tantalum ingots conforming to ASTM B521 or ASTM B365.

- Vacuum Melting: Electron beam or powder metallurgy refining ensures minimal gas impurities.

- Billet Forging: Multi-step hot forging for grain refinement and uniform structure.

- Extrusion & Piercing: Controlled hot extrusion followed by mandrel piercing to form the hollow tube.

- Cold Drawing: Multiple cold drawing passes with intermediate annealing to achieve final dimensions.

- Heat Treatment: Vacuum annealing for stress relief and microstructure optimization.

- Surface Finishing: Chemical polishing, mechanical grinding, or pickling for smooth internal/external surfaces.

- Final Inspection: Comprehensive dimensional, mechanical, and purity testing before shipment.

Each stage is supervised by qualified metallurgists to ensure the final tube meets tight dimensional tolerances and surface smoothness standards.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Shaanxi Chuanghui Daye implements a strict ISO 9001:2015 quality control system covering the full production cycle—from raw material to final inspection.

Quality Control Measures Include:

- Chemical Composition Testing: ICP-OES and GDMS analysis to verify purity.

- Mechanical Property Testing: Tensile strength, yield strength, and elongation according to ASTM B521.

- Dimensional Accuracy: Laser micrometer measurement for OD, ID, and wall thickness.

- Surface Quality Inspection: Microscopic surface evaluation for cracks and inclusions.

- Ultrasonic & Eddy Current Testing: Non-destructive evaluation to detect internal defects.

- Gas Impurity Analysis: Hydrogen, oxygen, and nitrogen content control to ensure high purity.

Each product is delivered with a Mill Test Certificate (MTC) and traceability documentation.

R&D and Customization

With over 30 years of metallurgical experience, Chuanghui Daye continuously improves its tantalum tube production process and offers flexible customization services to meet specialized requirements.

R&D Focus:

- Development of ultra-thin wall seamless tantalum tubes for semiconductor and microelectronics applications.

- Tantalum-tungsten (Ta-W) and tantalum-niobium (Ta-Nb) alloy tube innovations for enhanced strength and oxidation resistance.

- Precision machining and custom forming for complex components.

- Research into surface modification and oxide coating technologies.

Customization Options:

- Outer Diameter: 3 mm – 100 mm

- Wall Thickness: 0.2 mm – 10 mm

- Length: Up to 3000 mm or per customer design

- Custom alloys and tolerances available on request

Packaging & Global Logistics

Every tantalum seamless tube is carefully packaged to ensure purity, safety, and stability during international transport.

Packaging Standards:

- Vacuum-sealed or argon-filled packaging to prevent oxidation

- Soft foam or anti-rust paper for protection against impact and corrosion

- Export-grade wooden boxes with clear labeling (grade, size, batch number, country of origin)

Logistics Services:

- Global air freight (FedEx, DHL, UPS) for small and urgent orders

- Sea freight for bulk shipments

- Full export documentation including Certificate of Origin, MSDS, and Packing List

All packaging complies with international export standards to maintain product integrity.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye provides professional OEM and ODM services for tantalum seamless tubes used in high-end applications.

OEM Capabilities:

- Customized dimensions, tolerances, and surface finishes

- Integration with other metal components (welded joints, flanges, etc.)

- Private labeling, part marking, and special packaging

- Rapid prototyping and small-batch production

- Technical support and long-term material supply solutions

Our engineering team collaborates closely with clients to deliver cost-effective and technically reliable customized products.

Inspection Process

To maintain 100% quality assurance, each tube undergoes a multi-stage inspection before leaving the factory:

- Incoming Material Testing – Verification of chemical composition and certifications.

- Process Monitoring – In-process dimension control during extrusion and drawing.

- Heat Treatment Inspection – Microstructure and hardness verification after annealing.

- Non-Destructive Testing – Ultrasonic and eddy current examination.

- Final Measurement – Dimensional accuracy and visual inspection.

- Surface Cleaning & Packaging Review – Ultrasonic cleaning and packaging validation.

Only tubes meeting all inspection standards are approved for delivery.

Why Choose Us

- Over 30 Years of Expertise in refractory metal materials.

- ISO 9001:2015 Certified production system ensuring global quality compliance.

- High-purity tantalum sourced from trusted raw material suppliers.

- Advanced Equipment – Electron beam furnace, rolling, forging, and precision machining.

- Global Export Experience – Trusted by clients in 50+ countries.

- Fast Delivery & Professional Support – 7-day dispatch for standard products.

Shaanxi Chuanghui Daye is committed to being your reliable global partner for high-performance tantalum and niobium products.

|

|

|

|

|

|

FAQs

Q1: What purity grades do you offer for tantalum seamless tubes?

A1: We supply 99.95% and 99.99% purity levels, equivalent to ASTM B521 R05200 and R05400 grades.

Q2: Can you produce customized lengths and diameters?

A2: Yes, we manufacture tubes with OD from 3 mm to 100 mm and custom lengths up to 3000 mm or per drawing.

Q3: What surface finishes are available?

A3: Available finishes include polished, pickled, bright, and matte according to customer requirements.

Q4: How do you ensure dimensional accuracy?

A4: Each tube is measured with precision instruments and laser micrometers during and after production.

Q5: What are your standard delivery times?

A5: Standard sizes ship within 7–10 working days; customized orders typically require 3–4 weeks.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email