- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

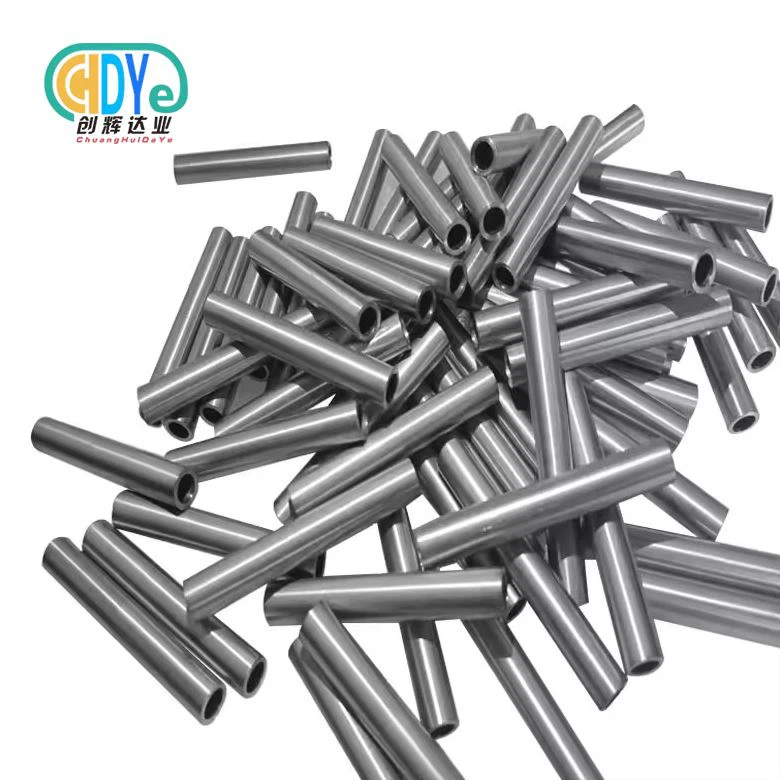

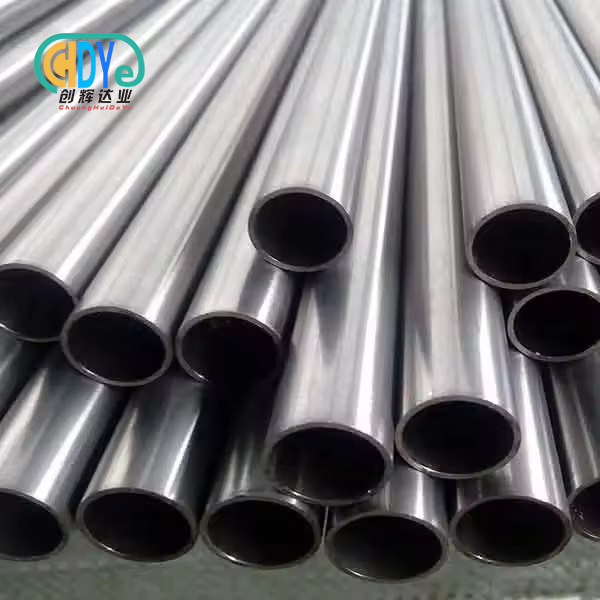

tantalum alloy wire

2. Diameter: 0.1–5 mm

3. Tensile strength: 250–400 MPa

4. Density: 16.7–17 g/cm³

5. Corrosion resistant

6. Applications: Aerospace, chemical

7. Elongation: 8–15%

Product Production

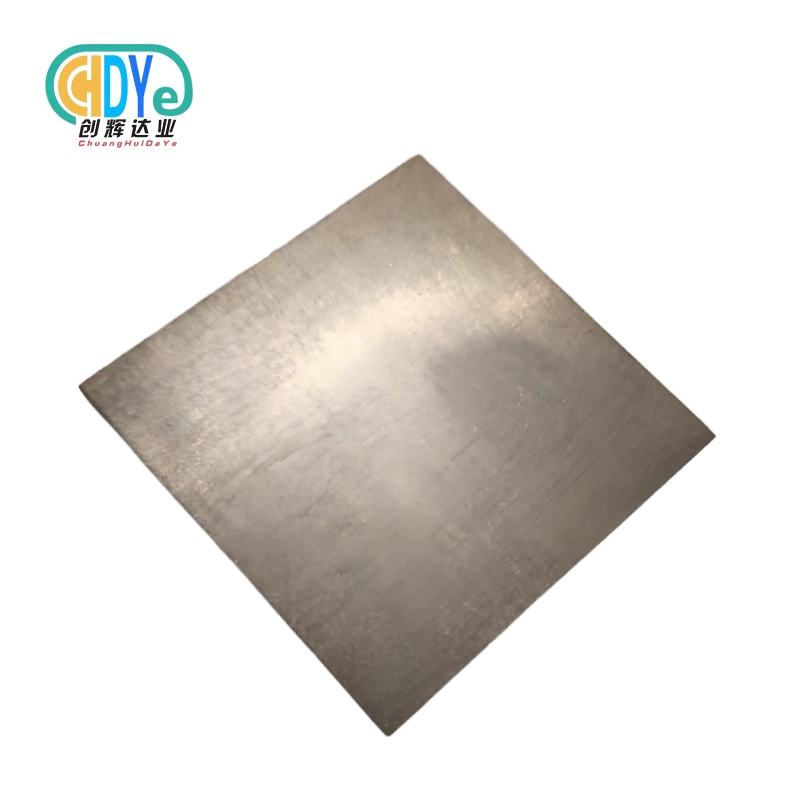

Looking for reliable tantalum alloy wire that delivers exceptional performance in demanding environments? Our high-grade tantalum alloy wire combines the superior properties of tantalum with carefully selected alloying elements to create a product that exceeds industry standards. With over 30 years of experience in rare metal manufacturing, we provide you with precision-engineered solutions that meet your most challenging requirements. Our products serve customers across 50+ countries worldwide, ensuring consistent quality and performance you can trust.

Key Features and Benefits

Our tantalum alloy products offer remarkable advantages for your critical applications:

- Superior Corrosion Resistance: Exceptional resistance to chemical attack in harsh environments

- High Tensile Strength: Delivers 250-400 MPa tensile strength for demanding applications

- Excellent Ductility: 8-15% elongation ensures easy processing and forming

- Biocompatibility: Safe for medical implants and biomedical devices

- Temperature Stability: Maintains properties at elevated temperatures

- Precision Manufacturing: Tight tolerances for consistent performance

Technical Specifications

| Property | Specification |

|---|---|

| Diameter Range | 0.5- 5.0 mm |

| Tensile Strength | 250 - 400 MPa |

| Density | 16.7 - 17.0 g/cm³ |

| Elongation | 8 - 15% |

| Purity | 99.95% min |

| Surface Finish | Bright annealed |

| Standard Length | as your requirements |

| Certificate | ISO 9001:2015 |

| Grade | Pure Tantalum (Ta), Ta-2.5W, Ta-10W |

| Delivery time | normal production time is about 15 days |

| Payment terms | 30%TT in advance,70% balance before shipment |

Chemical composition

|

Grade |

Chemical Composition (≤%) |

|||||||||||

|

Ta |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Nb |

O |

C |

H |

N |

|

|

Ta1 |

Bal. |

0.005 |

0.005 |

0.002 |

0.01 |

0.01 |

0.002 |

0.03 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

Ta2 |

Bal. |

0.03 |

0.02 |

0.005 |

0.04 |

0.03 |

0.005 |

0.1 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

TaNb3 |

Bal. |

0.03 |

0.03 |

0.005 |

0.04 |

0.03 |

0.005 |

<3.5 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

TaNb20 |

Bal. |

0.03 |

0.03 |

0.005 |

0.04 |

0.03 |

0.005 |

17.0-23.0 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

Ta2.5W |

Bal. |

0.005 |

0.005 |

0.002 |

3 |

0.01 |

0.002 |

0.04 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

Ta10W |

Bal. |

0.005 |

0.005 |

0.002 |

11 |

0.01 |

0.002 |

0.04 |

0.015 |

0.01 |

0.0015 |

0.01 |

Available Grades and Materials

We offer various tantalum alloy compositions to meet your specific needs:

Tantalum and Tantalum Alloy UNS Grade

R05200, unalloyed tantalum, electron-beam furnace vacuum-arc melt, or both

R05400, unalloyed tantalum, powder-metallurgy consolidation.

R05255, tantalum alloy, 90 % tantalum, 10 % tungsten, electron-beam furnace of vacuum-arc melt, or both.

R05252, tantalum alloy, 97.5 % tantalum, 2.5 % tungsten, electron-beam furnace vacuum-arc melt, or both.

R05240, tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt.

Other tantalum alloys also can be customized.

Each grade undergoes rigorous quality control to ensure consistent chemical composition and mechanical properties.

Manufacturing Process

Our advanced manufacturing process ensures superior quality:

- Raw Material Selection: Premium tantalum and alloying elements

- Vacuum Melting: Controlled atmosphere processing

- Hot Working: Precision forging and rolling

- Cold Drawing: Multiple passes for dimensional accuracy

- Heat Treatment: Optimized annealing for desired properties

- Quality Testing: Comprehensive inspection and certification

|

|

|

|

|

|

|

|

Applications and Industries

Our tantalum alloy wire serves diverse industries:

- Aerospace: Jet engine components and heat exchangers

- Chemical Processing: Corrosion-resistant equipment parts

- Medical Devices: Surgical instruments and implants

- Electronics: High-performance electronic components

- Nuclear Industry: Reactor components and containment systems

- Research: Laboratory equipment and experimental apparatus

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain strict dimensional controls:

- Diameter Tolerance: ±0.02 mm for diameters ≤1 mm, ±0.05 mm for larger sizes

- Length Tolerance: ±5 mm standard, tighter tolerances available

- Straightness: 0.5 mm per meter maximum deviation

- Surface Quality: Ra ≤ 0.8 μm

Product Features in Detail

Corrosion Resistance

Your wire maintains integrity in aggressive chemical environments, including hydrochloric acid, sulfuric acid, and alkaline solutions.

Mechanical Properties

The balanced strength and ductility allow for complex forming operations while maintaining structural integrity under stress.

Thermal Stability

High melting point and low thermal expansion coefficient ensure dimensional stability across temperature ranges.

Quality Assurance and Testing

Every batch undergoes comprehensive testing:

- Chemical composition analysis

- Tensile strength testing

- Dimensional inspection

- Surface quality evaluation

- Microstructure examination

We maintain ISO quality management systems to ensure consistent product excellence.

OEM & Customization Services

We understand your unique requirements. Our engineering team works closely with you to develop custom solutions:

- Modified alloy compositions

- Special dimensions and tolerances

- Custom packaging requirements

- Technical support and consultation

Packaging and Shipping

Your products arrive safely with our protective packaging:

- Individual wire protection with foam padding

- Moisture-resistant packaging materials

- Clear labeling with specifications

- Secure shipping containers

- Worldwide delivery capabilities

|

|

|

Why Choose Us

With three decades of rare metal expertise, we deliver value through:

- Proven Experience: 30+ years in rare metal manufacturing

- Global Reach: Serving customers in 50+ countries

- Quality Focus: Rigorous testing and quality control

- Technical Support: Expert engineering assistance

- Competitive Pricing: Direct manufacturer pricing

- Reliable Delivery: On-time shipment guarantee

Located in China's "Titanium Capital," we leverage regional expertise and resources to provide you with exceptional products and service.

|

|

|

|

|

|

FAQs

Q: What is the minimum order quantity?

A: We accommodate orders from small prototype quantities to large production runs.

Q: Can you provide material certificates?

A: Yes, we provide complete material test reports with each shipment.

Q: What lead times can you offer?

A: Standard products ship within 1-2 weeks, custom orders typically require 2-3 weeks.

Q: Do you offer technical support?

A: Our experienced engineers provide comprehensive technical assistance throughout your project.

Contact Us

Ready to discuss your tantalum alloy wire requirements? Our technical team stands ready to help you select the optimal solution for your application.

Email: info@chdymetal.com

Mob./what's app: 86-18049386902

Contact us today for detailed specifications, pricing, and technical consultation. We look forward to becoming your trusted partner for premium rare metal solutions.

Learn about our latest products and discounts through SMS or email