- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

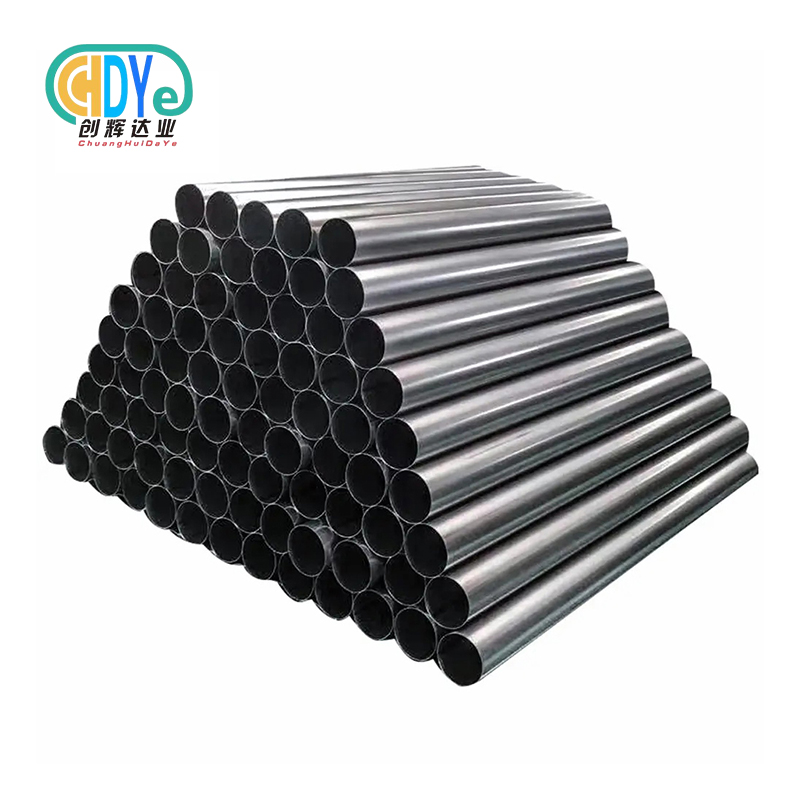

IrO2 Coated Titanium Anode

Product Introduction

Chdymetal can provide various titanium anodes, customized is accepted. titanium anode use pure titanium material as substrate, has high anti-corrosion and high catalytic activity. MMO coated anode has long working life .For the important, the substrate could be reused.

|

Substrate: pure titanium |

coating:Iridium-Tantalum |

|

Current density:≤2000 A/m² |

Coating content≥5g/ m² |

|

Coating thickness ≥ 10μm |

Oxygen evolution potential1.5 v relative to calomel electrode |

Advantages:

1) Low cell voltage and low power consumption

2) Dimensional stable

3) Good anti-corrosion, little dissolution of anode to keep clean plating electrolyte and solid plating on workpiece.

4) Light weight of titanium anode could make daily operations easily.

5) Reusability of titanium substrate, long life span and low cost.

6) Low oxygen evolution potential of titanium anode (0.5V lower than lead alloy anode's OEP), cell voltage is reduced, power consumption cost is reduced a lot.

7) Activation layer is coated before Ir-Ta coating, anode's activity is improved and life span is prolonged.

Application Advantages

IrO₂ Coated Titanium Anode is widely recognized for its excellent electrochemical stability and long service life in harsh operating environments. The anode features a stable coating of iridium oxide, providing exceptional performance in chloride and oxygen evolution reactions.

Key advantages include:

- Outstanding corrosion and wear resistance

- High catalytic activity and low overpotential

- Uniform current distribution for improved efficiency

- Energy savings and longer maintenance intervals

- Suitable for both acidic and neutral electrolytes

Be used in a wide range of industries.

Seawater electrolysis

Marine aquaculture

Chlor-alkali industry

Cathodic protection

Electroplating industry

Non-ferrous metal electrolytic extraction

Manufacturing & Process Flow

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality is guaranteed through a full-spectrum inspection system covering each production stage.

Main inspection points:

- Raw material testing: Purity and microstructure verification of titanium substrate.

- Coating adhesion test: Cross-hatch and ultrasonic tests ensure strong bonding.

- Electrochemical performance: Accelerated life testing in acidic media.

- Dimensional accuracy: Precision measurement and visual inspection.

- Final inspection: Each anode is serialized and certified before packaging.

R&D and Customization

Our R&D team continuously explores new coating formulations and deposition technologies to enhance anode performance.

Customization options include:

- Tailored coating ratios (IrO₂/RuO₂/Ta₂O₅ mixed coatings)

- Substrate thickness and shape customization

- Optimized coating thickness for specific current densities

- Prototyping for laboratory or pilot-scale testing

Packaging & Global Logistics

To ensure product integrity during global transportation, each IrO₂ Coated Titanium Anode is packed with multiple protection layers.

Packaging details:

- Vacuum-sealed or anti-rust film wrapping

- Foam cushioning and moisture barrier

- Export-standard wooden cases

Logistics:

- Reliable air, sea, and express delivery worldwide

- Clear labeling with product code and batch number

- Real-time logistics tracking and customs documentation support

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

We provide flexible OEM and ODM services to meet specific application requirements:

- Coating composition design and optimization

- Customized titanium substrate machining

- Private labeling and marking

- Small-batch production for trial projects

- Full technical documentation and test reports

Inspection Process

Each production batch follows a standardized inspection protocol:

- Visual and dimension inspection

- Coating thickness and uniformity measurement

- Adhesion test (Cross-cut or bending)

- Electrochemical test (potential & current stability)

- Service life simulation under accelerated conditions

All inspection results are recorded and traceable for every product batch.

Why Choose Us

- Over 30 years of experience in rare metal electrode manufacturing

- Advanced coating technology and precise process control

- Certified ISO 9001:2015 quality management system

- Fast delivery within 7–10 days

- Exported to 50+ countries worldwide

- Dedicated technical and after-sales support team

|

|

|

|

|

|

FAQs

Q1: What is the lifespan of IrO₂ Coated Titanium Anode?

A1: Typically ranges from 2 to 10 years depending on current density, electrolyte type, and operating conditions.

Q2: Can the anode be used in seawater electrolysis?

A2: Yes, IrO₂ coating offers strong resistance to chloride corrosion, suitable for seawater electrolysis and chlor-alkali applications.

Q3: Do you provide sample or trial orders?

A3: Yes, small-batch and prototype samples are available for testing and validation.

Q4: Can you customize the coating composition?

A4: Absolutely, we can tailor IrO₂/RuO₂ or IrO₂/Ta₂O₅ mixtures based on specific electrochemical needs.

Q5: What support is offered after delivery?

A5: We provide full technical consultation, lifetime performance tracking, and timely replacement or re-coating services when needed.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email