- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

titanium niobium wires

2. Diameter: 0.5–5 mm

3. Length: customized

4. Density: 4.5–8.6 g/cm³

5. Tensile strength: 200–400 MPa

6. Applications: Medical, electronics

7. Corrosion resistant

Product Introduction

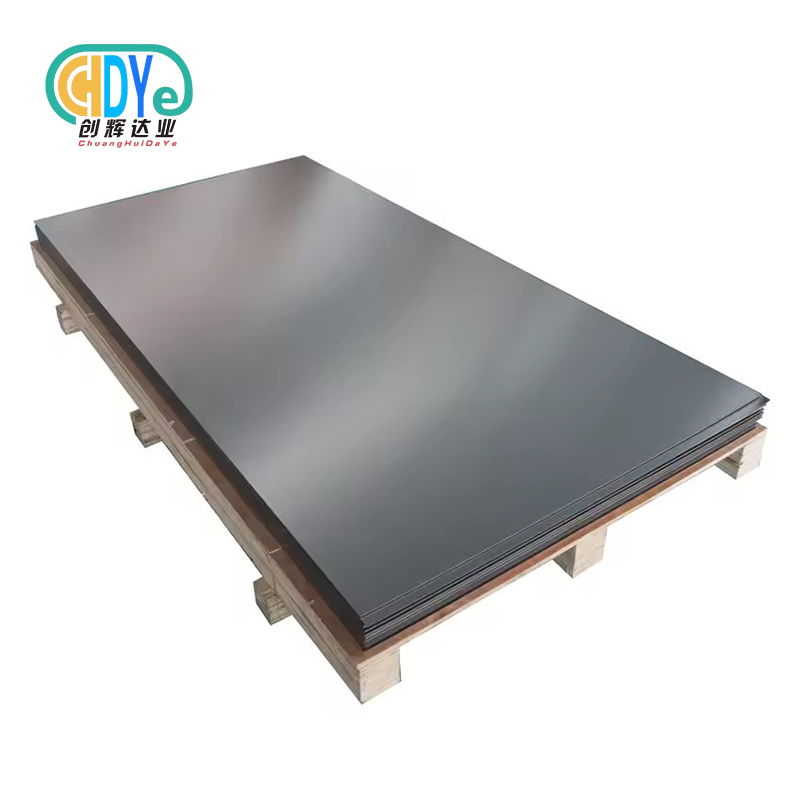

Are you looking for high-performance titanium niobium wires that deliver exceptional strength and corrosion resistance? Our titanium niobium wires combine the best properties of both metals, offering superior mechanical characteristics for demanding applications. With diameters ranging from 0.5 to 5 mm and lengths can be customized these specialized alloy wires meet the most stringent requirements in medical, electronics, and industrial applications. Our Ti-Nb alloy wires provide excellent biocompatibility and durability you can trust.

Key Features and Benefits

- Superior Corrosion Resistance: Withstands harsh chemical environments

- Excellent Biocompatibility: Perfect for medical and dental applications

- High Tensile Strength: Delivers reliable performance under stress

- Precision Manufacturing: Consistent quality and dimensional accuracy

- Versatile Applications: Suitable for multiple industries

- Customizable Specifications: Tailored to your specific requirements

Technical Specifications

| Parameter | Specification |

|---|---|

| Alloy Type | Ti-Nb (Titanium-Niobium) |

| Diameter Range | 0.5- 5.0 mm |

| Maximum Length | 1000 mm |

| Density | 4.5 - 8.6 g/cm³ |

| Tensile Strength | 200 - 400 MPa |

| Surface Finish | Bright, pickled |

| Temperature Range | -200°C to +400°C |

| Grade | Nb53-Ti47, Nb50%-Ti50%, and Nb45%-Ti55%. |

| Certificate | ISO 9001:2015 |

| Condition | Annealed |

| Delivery time | Normal need 10-15 working days mainly according to your quantity |

| Payment terms | 30%TT in advance, 70% TTbalance payment before shipment |

Available Grades and Materials

We offer various titanium-niobium compositions to meet your specific needs. Our standard grades include different Ti-Nb ratios optimized for particular applications. Each grade undergoes rigorous testing to ensure consistent properties and performance.

Manufacturing Process

Our titanium niobium wires are produced using advanced metallurgical techniques. The process begins with high-purity raw materials that undergo precise alloying. Cold drawing and heat treatment processes ensure optimal mechanical properties and surface finish. Quality control measures are implemented at every stage.

|

|

|

|

|

|

|

|

Applications and Industries

Medical Sector

- Surgical instruments and implants

- Orthodontic devices and dental tools

- Cardiovascular applications

Electronics Industry

- Precision electronic components

- Superconducting applications

- Specialized sensors

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Research and Development

- Laboratory equipment

- Scientific instruments

- Experimental devices

Product Dimensions and Tolerances

Our wire dimensions maintain tight tolerances to ensure consistent performance. Standard diameter tolerances are ±0.01 mm for sizes below 1 mm and ±0.02 mm for larger diameters. Length tolerances are maintained within ±2 mm for standard products.

Product Features in Detail

The unique combination of titanium and niobium creates wires with exceptional properties. These alloys offer improved ductility compared to pure titanium while maintaining excellent corrosion resistance. The biocompatible nature makes them ideal for medical applications where human contact is involved.

Quality Assurance and Testing

Every batch undergoes comprehensive testing including tensile strength analysis, chemical composition verification, and dimensional inspection. Our quality management system ensures consistent product performance and reliability.

|

|

|

OEM & Customization Services

We specialize in custom wire solutions tailored to your specifications. Our engineering team works closely with you to develop products that meet your exact requirements. From prototype development to full-scale production, we support your project needs.

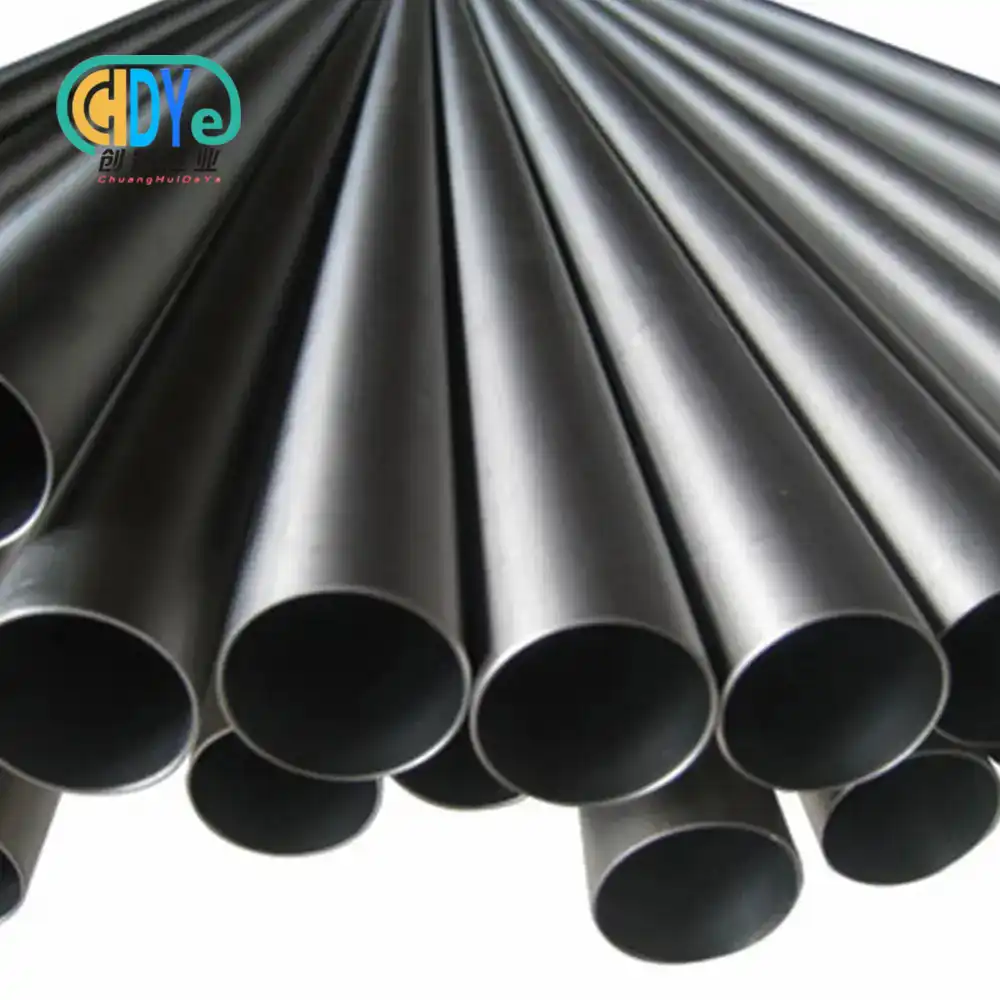

Packaging and Shipping

Products are carefully packaged to prevent damage during transit. We use protective materials and proper handling procedures to ensure your order arrives in perfect condition. Shipping options include express delivery for urgent requirements.

Why Choose Us

Located in China's "Titanium Capital," we bring over 30 years of experience in rare metal processing. Our commitment to quality and customer satisfaction has earned trust from clients in over 50 countries. We provide competitive pricing, reliable delivery, and exceptional technical support.

|

|

|

|

|

|

FAQs

Q: What makes titanium niobium wires special?

A: The combination offers enhanced mechanical properties and superior corrosion resistance compared to individual metals.

Q: Can you provide custom specifications?

A: Yes, we offer complete customization services for diameter, length, and composition requirements.

Q: What industries use these products?

A: Primary applications include medical devices, electronics, and research equipment.

Q: How do you ensure quality?

A: We implement strict quality control measures including material testing and dimensional verification.

Contact Us

Ready to discuss your titanium niobium wire requirements? Our technical team is here to help you find the perfect solution for your application.

Email: info@chdymetal.com

Mob./what's app.: 86-18049386902

Contact us today for competitive quotes, technical specifications, or custom product development. We look forward to partnering with you for all your specialized metal wire needs.

Learn about our latest products and discounts through SMS or email