- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

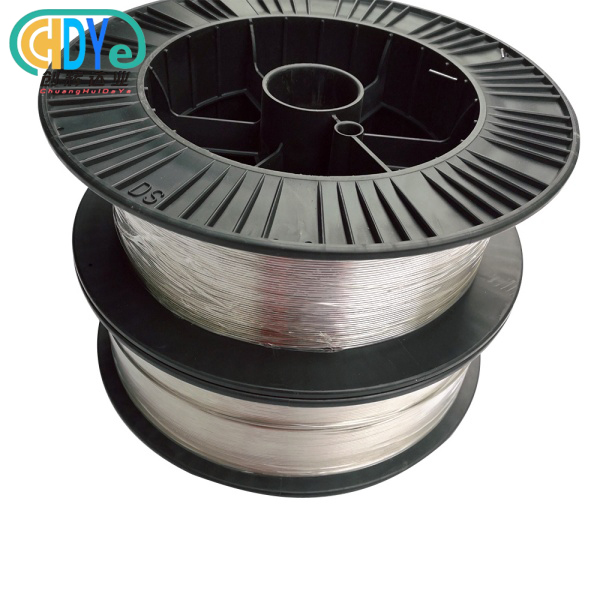

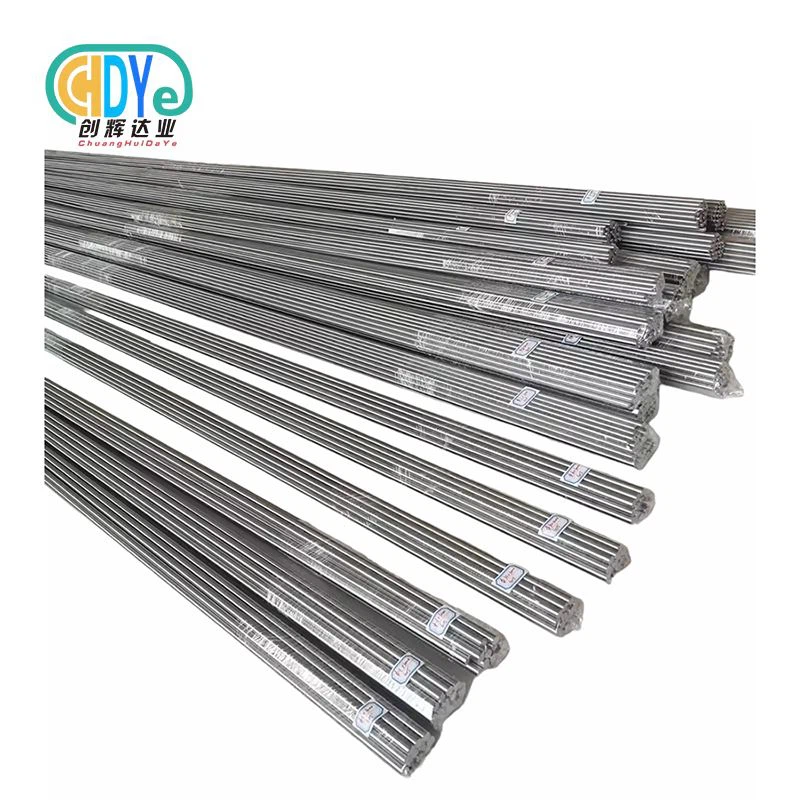

tantalum bar tantalum rod

2. Diameter: 1–50 mm

3. Length: 500- 1000 mm and customized

4. Density: 16.65 g/cm³

5. Tensile strength: 200–300 MPa

6. Applications: Chemical, electronics

7. Shape: Bar/Rod

Product Introduction

Chdymetal offers top-quality tantalum bar tantalum rod at competitive prices with purities of 99.95% and 99.99%, providing customization service to meet specific needs. Tantalum and tantalum alloys possess a range of outstanding properties, including high melting point, low vapor pressure, excellent cold workability, high chemical stability, strong resistance to liquid metal corrosion, and a high dielectric constant of the surface oxide film. so they have significant applications in high-tech fields such as electronics, metallurgy, steel production, chemical industry, aerospace, medical and healthcare, as well as scientific research.

Key Features and Benefits

Our tantalum products deliver outstanding performance through several key advantages:

- Superior Corrosion Resistance: Naturally occurring oxide film provides excellent protection against aggressive chemicals

- High Temperature Stability: Maintains structural integrity in extreme thermal conditions

- Biocompatibility: Safe for medical device applications and human contact

- Excellent Workability: Can be machined, rolled, milled, or threaded to your specifications

- Long Service Life: Exceptional durability reduces replacement costs and downtime

Technical Specifications

|

Product name |

tantalum bar tantalum rod |

|

Purity |

99.95% Min |

|

Density |

16.65g/cm3 |

|

Surface |

Polished and Black |

|

Size |

Φ2.0—100mm*L,customized |

|

Melting point |

3400℃ |

|

Packing |

Wooden box |

|

Production process |

Tantalum raw material - electron beam vacuum melting - forging - polishing - inspection - delivery |

|

Packing term |

Foam packing inside, wooden box outside |

|

Delivery time |

Stock size within 1-5 days normal production time about 15 days |

|

Express |

DHL,Fedex, TNT by air,by sea |

|

Payment term |

30%TT in advance,70% balance before shipment |

Chemical Composition

|

Grade |

Chemical Composition (≤%) |

||||||||||||

|

Ta |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Nb |

O |

C |

H |

N |

||

|

Ta1 |

Bal. |

0.005 |

0.005 |

0.002 |

0.01 |

0.01 |

0.002 |

0.03 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

|

Ta2 |

Bal. |

0.03 |

0.02 |

0.005 |

0.04 |

0.03 |

0.005 |

0.1 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

|

TaNb3 |

Bal. |

0.03 |

0.03 |

0.005 |

0.04 |

0.03 |

0.005 |

<3.5 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

|

TaNb20 |

Bal. |

0.03 |

0.03 |

0.005 |

0.04 |

0.03 |

0.005 |

17.0-23.0 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

|

Ta2.5W |

Bal. |

0.005 |

0.005 |

0.002 |

3.0 |

0.01 |

0.002 |

0.04 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

|

Ta10W |

Bal. |

0.005 |

0.005 |

0.002 |

11 |

0.01 |

0.002 |

0.04 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

Physical properties

|

Grade(UNS) |

Annealed |

||

|

Tensile strength min,psi (MPa) |

Yield strength min,psi (MPa)(2%) |

Elongation min,% (1 inch gage length) |

|

|

Pure Ta (RO5200,RO5400) |

30000 (207) |

20000 (138) |

20 |

|

Ta-10W (RO5255) |

70000 (482) |

60000 (414) |

15 |

|

Ta-2.5W (RO5252) |

40000 (276) |

30000 (207) |

20 |

|

Ta-40Nb (RO5240) |

35000 (241) |

20000 (138) |

25 |

Available Grades and Materials

We supply various tantalum grades to meet your specific requirements:

- Commercial Pure Tantalum: 99.9% minimum purity for general applications

- High-Purity Tantalum: 99.95% purity for electronics and semiconductor use

- Custom Alloys: Tantalum-tungsten and other specialized compositions available

Manufacturing Process

Our tantalum bar tantalum rod manufacturing involves sophisticated cold-working techniques. We start with premium tantalum ingots and employ forging, rolling, swaging, and drawing processes either individually or in combination. This approach ensures consistent quality and precise dimensional control throughout production.

Quality control measures are implemented at every stage to guarantee your products meet exact specifications.

|

|

|

|

|

|

|

|

Applications and Industries

These versatile products serve numerous critical applications:

Chemical Processing: Valve components, reactor vessels, and piping systems

Electronics: Capacitor elements and semiconductor components

Medical Devices: Prosthetic implants and surgical instruments

Aerospace: High-temperature alloy additives and specialized components

Energy: Vacuum furnace heating elements and power generation equipment

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We maintain strict dimensional tolerances to ensure perfect fit in your applications:

- Diameter tolerance: ±0.05mm for precision applications

- Length tolerance: ±1mm standard, tighter tolerances available

- Surface finish: As-drawn or polished options

- Straightness: Within 0.5mm per meter

Product Features in Detail

The exceptional properties of our products stem from tantalum's unique characteristics. The material exhibits corrosion resistance comparable to glass, making it ideal for harsh chemical environments. Its inertness to organic and inorganic compounds ensures consistent performance across diverse applications.

The natural biocompatibility makes these materials perfect for medical applications where tissue compatibility is crucial.

Quality Assurance and Testing

Every product undergoes comprehensive testing including:

- Chemical composition analysis

- Dimensional verification

- Surface quality inspection

- Mechanical property testing

- Corrosion resistance validation

We maintain detailed quality records and provide certificates of compliance with your orders.

|

|

|

OEM & Customization Services

Our experienced team provides comprehensive customization services:

- Custom dimensions and tolerances

- Specialized surface treatments

- Unique alloy compositions

- Application-specific engineering support

- Prototype development and testing

Packaging and Shipping

Products are carefully packaged to prevent damage during transit:

- Individual protective wrapping

- Moisture-resistant packaging

- Secure shipping containers

- International shipping capabilities

- Tracking and insurance options

Why Choose Us

Located in China's "Titanium Capital," we combine three decades of industry expertise with modern manufacturing capabilities. Our founder's extensive experience in rare metals ensures you receive products that exceed expectations. We serve customers in over 50 countries, building lasting relationships through quality, reliability, and competitive pricing.

Our commitment to customer satisfaction drives continuous improvement in products and services.

|

|

|

|

|

|

FAQs

Q: What's the minimum order quantity?

A: We accommodate both small prototype orders and large production quantities.

Q: Can you provide custom dimensions?

A: Yes, we specialize in custom tantalum bar tantalum rod manufacturing to your exact specifications.

Q: What's the typical lead time?

A: Standard products ship within 2-3 weeks; custom orders may require 3-4 weeks.

Q: Do you provide material certificates?

A: Yes, we provide complete material certification with every shipment.

Contact Us

Ready to discuss your requirements? Our technical team is here to help you select the perfect tantalum bar tantalum rod solution for your application.

Email: info@chdymetal.com

Contact us today for detailed quotations, technical specifications, or application engineering support. We look forward to becoming your trusted partner for premium tantalum products.

Learn about our latest products and discounts through SMS or email