- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

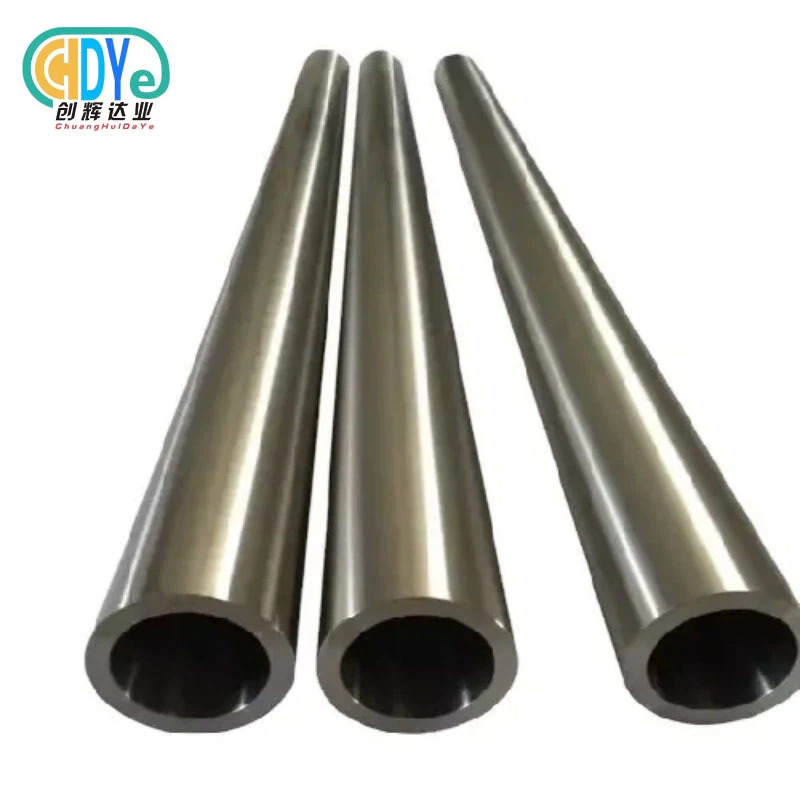

TZM Molybdenum Alloy Tube

Product Introduction

The TZM Molybdenum Alloy Tube manufactured by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a high-performance material designed for extreme thermal and mechanical environments. Composed primarily of molybdenum, titanium, and zirconium, this alloy provides superior strength, high-temperature resistance, and excellent creep properties compared to pure molybdenum. The tube demonstrates remarkable dimensional stability, wear resistance, and corrosion tolerance under prolonged exposure to high temperatures, making it an indispensable component for advanced engineering and industrial applications.

As a leading producer of refractory metal materials with over 30 years of experience, Chuanghui Daye ensures that every TZM Molybdenum Alloy Tube meets the highest international standards. The product is available in a wide range of diameters and wall thicknesses, all manufactured under ISO 9001:2015-certified quality control systems to ensure precise dimensions, fine microstructure, and consistent mechanical properties.

TZM is Molybdenum's prime alloy and is an alloy of titanium, zirconium and carbon.TZM molybdenum alloy Tubes are available in both round and square shapes and in numerous standard and custom dimensions.TZM Molybdenum (TZM Alloy) has a higher recrystallization temperature, higher strength, hardness at room and elevated temperatures than pure Molybdenum.

Specification

Material:TZM molybdenum

Standard: ASTM B387

Process: Sintering, drilling

Surface: Finish Turning, Grinding

Characteristics:

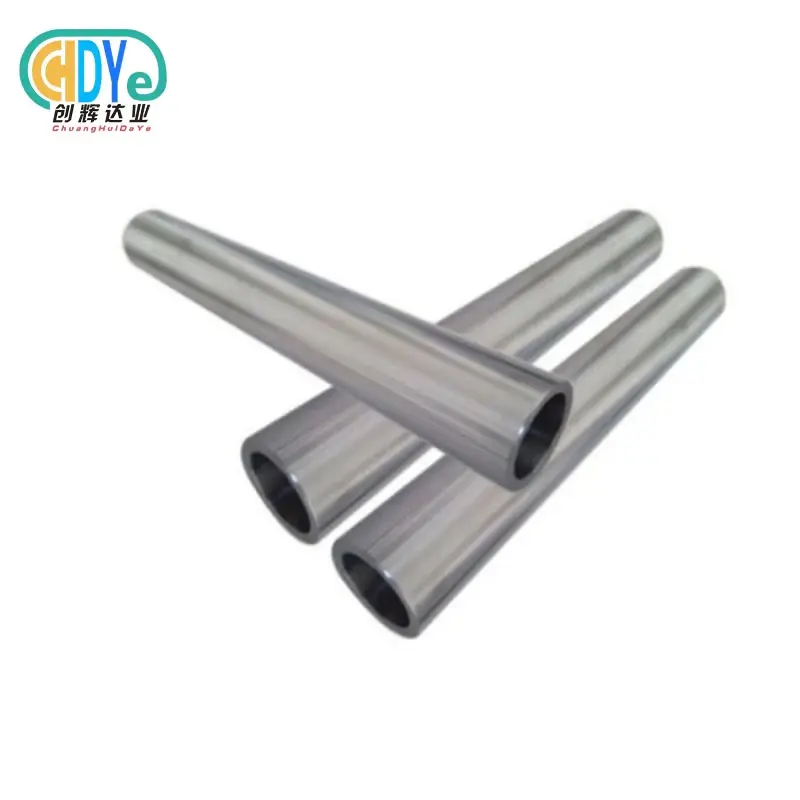

1. High temperature performance: TZM molybdenum alloy pipe has a high melting point (2617 ℃) and high temperature strength, which can maintain stable mechanical properties in high temperature environments and is suitable for use in high-temperature industries.

2. Mechanical properties: TZM molybdenum alloy pipe has high strength, high elastic modulus, and low coefficient of linear expansion, which makes it perform well under various stress conditions.

3. Corrosion resistance: TZM molybdenum alloy pipes have good corrosion resistance and can be used in various corrosive environments, extending their service life.

4. Processing performance: TZM molybdenum alloy pipes have good processing performance and can be prepared by powder metallurgy and rolling deformation methods. They also have high recrystallization temperature and good creep resistance.

Main products:

1) Pure molybdenum products: molybdenum powder, slabs, bars, rolling plates, sheets, rods (electrodes), wires, crucibles, boats, funnels and other special shape molybdenum products.

2) Molybdenum alloy products: MLR plates, MLR rods, TZM plates, wires and other molybdenum alloy products.

Application Advantages

TZM molybdenum alloy pipes are widely used in aerospace, weapon electronics, nuclear power medical and other fields, commonly used in electronic tube cathodes, gates, high-voltage rectifier components, semiconductor thin-film integrated circuits, etc. in the electronic and electrical industry; On nuclear energy equipment such as radiation hoods, support frames, heat exchangers, rails, etc

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Quality Control & Inspection

Quality is the foundation of Chuanghui Daye’s success. The company operates under a fully implemented ISO 9001:2015 quality management system. The quality control and inspection process includes:

Chemical Composition Verification: Confirming alloy ratios through advanced spectrometric analysis.

Ultrasonic and Eddy Current Testing: Ensuring structural uniformity and detecting internal defects.

Mechanical Testing: Verifying tensile strength, hardness, and elongation according to ASTM standards.

Dimensional and Surface Inspection: Using precision tools to ensure compliance with customer specifications.

Cleanroom Packaging Inspection: Final visual and contamination checks before shipment.

Only products that pass all inspection stages are approved for export, guaranteeing consistent quality and reliability.

R&D and Customization

With a highly skilled R&D team and advanced metallurgical facilities, Shaanxi Chuanghui Daye continuously improves its alloy processing and forming technologies. We provide:

Custom composition adjustments to optimize performance.

Special sizes, wall thicknesses, and tolerances according to technical drawings.

Advanced forming solutions for complex geometries.

Joint development projects for aerospace and energy applications.

Packaging & Global Logistics

All products are packaged to international export standards to ensure safe and secure transportation:

Packaging Materials: Vacuum or anti-rust wrapping, foam lining, and wooden crates.

Marking: Each package is labeled with product name, specification, and batch number.

Transport Options: Reliable air, sea, or land shipping to meet customer deadlines.

Shaanxi Chuanghui Daye’s efficient logistics network ensures that shipments arrive safely in over 50 export markets, including the United States, Germany, South Korea, Japan, and France.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

We provide comprehensive OEM and ODM services to meet the unique needs of global clients. Our services include:

Custom material compositions and dimensions.

Prototype and pilot-scale production.

Professional consultation on design and material selection.

Consistent supply for large-scale industrial operations.

Each project is handled by a dedicated technical team to ensure every TZM Molybdenum Alloy Tube meets the customer’s precise application requirements.

Inspection Process

Our inspection system combines advanced testing methods with meticulous manual verification:

Raw Material Check: Purity and alloy composition validation.

Intermediate Testing: Ultrasonic examination after hot working.

Dimensional and Visual Inspection: Ensuring perfect roundness and smooth surface finish.

Mechanical Property Testing: Conducted on representative samples.

Final Audit and Certification: Each batch accompanied by detailed inspection reports.

This rigorous inspection guarantees that every shipment fulfills both domestic and international quality standards.

Why Choose Us

30+ Years of Manufacturing Experience in refractory metals.

ISO 9001:2015 Certified production system.

Comprehensive Material Range: Titanium, Molybdenum, Tungsten, Niobium, and Tantalum.

Precision Machining Capabilities for custom projects.

Global Delivery Network covering 50+ countries.

Reliable OEM & ODM Services for industrial clients.

Our commitment to quality, innovation, and customer satisfaction has made Shaanxi Chuanghui Daye a trusted global supplier of high-performance metal materials.

|

|

|

|

|

|

FAQs

Q1: What is the typical composition of TZM alloy?

A: TZM is composed of approximately 0.5% titanium, 0.08% zirconium, and the balance molybdenum, with small carbon additions to improve strength.

Q2: What temperature range can the tube withstand?

A: The alloy maintains high strength and stability up to 1400–1600°C in inert or vacuum environments.

Q3: Can you produce custom sizes or shapes?

A: Yes, we can manufacture customized tubes, rods, or parts based on technical drawings and specific requirements.

Q4: What standards are your products manufactured to?

A: Our products comply with ASTM B387, GB/T 4182, and ISO standards for molybdenum and its alloys.

Q5: Do you provide third-party testing or certification?

A: Yes, third-party inspection services such as SGS or BV are available upon request.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email