- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

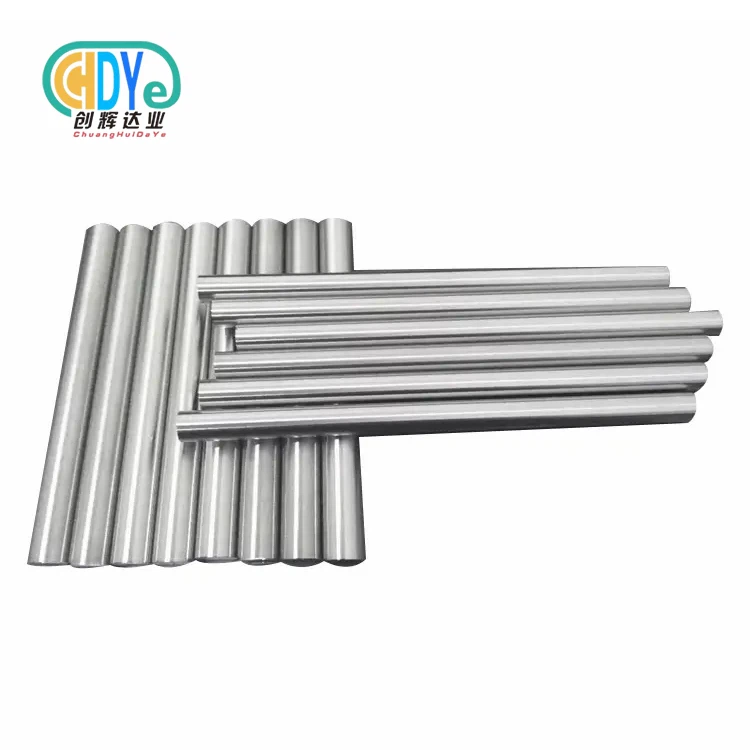

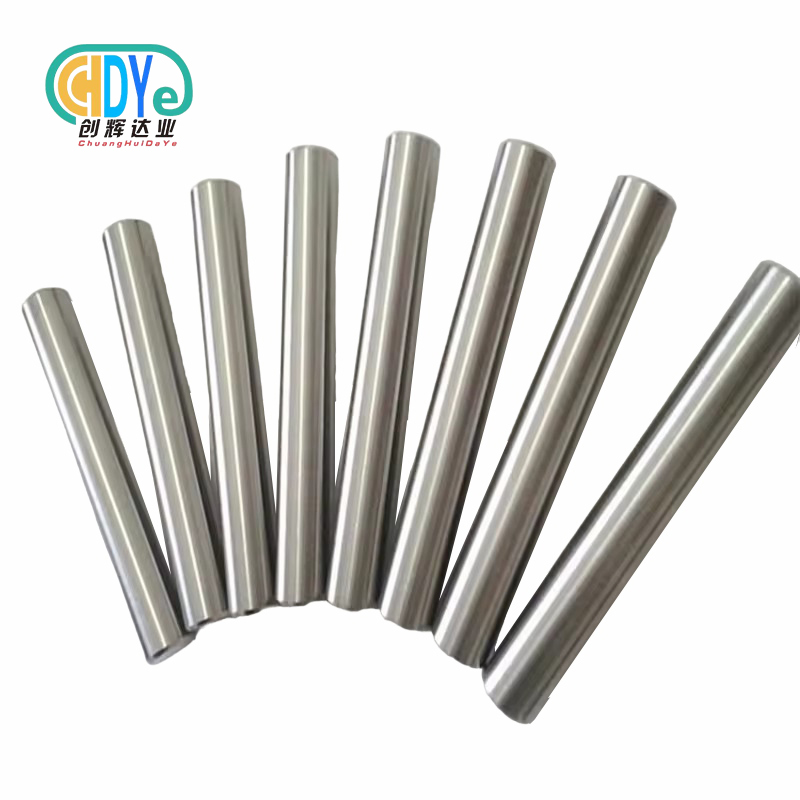

1.2mm tantalum wire

2. Diameter: 0.5–5 mm

3. Surface: Polished

4. Tensile strength: 200–300 MPa

5. Density: 16.65 g/cm³

6. Applications: Electronics, chemical

Product Introduction

When you need exceptional corrosion resistance and reliability in extreme conditions, our 1.2mm tantalum wire delivers unmatched performance. With over 30 years of experience in rare metal manufacturing, we provide superior quality tantalum wire solutions for demanding applications across electronics, chemical processing, and specialized industrial sectors.

Our tantalum wire products combine excellent mechanical properties with outstanding chemical resistance. You'll find these wires maintain their integrity even in the harshest environments, making them ideal for critical applications where failure is not an option.

Key Features and Benefits

- Superior Corrosion Resistance: Virtually immune to chemical attack below 150°C

- High Purity: Tantalum content exceeds 99.9% for optimal performance

- Excellent Ductility: Easy to shape and form without compromising strength

- Biocompatibility: Safe for medical and surgical applications

- Temperature Stability: Maintains properties across wide temperature ranges

- Precision Manufacturing: Tight dimensional tolerances ensure consistent quality

Technical Specifications

| Property | Specification |

|---|---|

| Alloy Composition | Ta >99.9% |

| Diameter Range | 0.5–5 mm |

| Surface Finish | Bright surface |

| Tensile Strength | 200–300 MPa |

| Density | 16.65 g/cm³ |

| Melting Point | 3017°C |

| Electrical Resistivity | 13.5 μΩ·cm |

| Thermal Conductivity | 57.5 W/m·K |

| Certificate | ISO 9001:2015 |

| Condition | Annealed |

| Standard | ASTM B365 |

| Production time | Normal production time need about 7-15 days |

Chemical composition

|

Grade |

Chemical Composition (≤%) |

|||||||||||

|

Ta |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Nb |

O |

C |

H |

N |

|

|

Ta1 |

Bal. |

0.005 |

0.005 |

0.002 |

0.01 |

0.01 |

0.002 |

0.03 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

Ta2 |

Bal. |

0.03 |

0.02 |

0.005 |

0.04 |

0.03 |

0.005 |

0.1 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

TaNb3 |

Bal. |

0.03 |

0.03 |

0.005 |

0.04 |

0.03 |

0.005 |

<3.5 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

TaNb20 |

Bal. |

0.03 |

0.03 |

0.005 |

0.04 |

0.03 |

0.005 |

17.0-23.0 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

Ta2.5W |

Bal. |

0.005 |

0.005 |

0.002 |

3 |

0.01 |

0.002 |

0.04 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

Ta10W |

Bal. |

0.005 |

0.005 |

0.002 |

11 |

0.01 |

0.002 |

0.04 |

0.015 |

0.01 |

0.0015 |

0.01 |

Available Grades and Materials

We offer various tantalum grades to meet your specific requirements:

- Commercial Pure Tantalum: Standard grade for general applications

- High-Purity Tantalum: Enhanced purity for specialized electronics

- Tantalum Alloys: Custom compositions available upon request

Manufacturing Process

Our manufacturing process ensures consistent quality and precision. We start with high-grade tantalum ingots, which undergo careful melting and casting. The material is then drawn through precision dies to achieve the desired diameter. Finally, each wire receives our specialized polishing treatment, creating a smooth, lustrous surface that enhances performance and appearance.

Quality control measures are implemented at every step to guarantee you receive products that meet your exact specifications.

|

|

|

|

|

|

|

|

Applications and Industries

Electronics Industry

- Capacitor manufacturing

- Circuit components

- Semiconductor devices

Chemical Processing

- Heat exchangers

- Reaction vessels

- Corrosive environment equipment

Medical Applications

- Surgical instruments

- Implantable devices

- Laboratory equipment

Aerospace & Defense

- High-temperature applications

- Specialized components

- Critical system elements

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

Our precision manufacturing capabilities allow us to maintain tight tolerances:

- Diameter Tolerance: ±0.01 mm for diameters ≤1 mm

- Diameter Tolerance: ±0.02 mm for diameters >1 mm

- Straightness: Within 0.5 mm per meter

- Surface Finish: Ra ≤0.2 μm

Quality Assurance and Testing

Every batch undergoes comprehensive testing including:

- Chemical composition analysis

- Mechanical property testing

- Dimensional verification

- Surface quality inspection

- Purity confirmation

We maintain detailed quality records for full traceability, ensuring you can trust the consistency of our products.

OEM & Customization Services

We understand that your applications may require specific configurations. Our experienced team can work with you to develop custom solutions including:

- Special diameter requirements

- Unique length specifications

- Custom packaging options

- Modified surface treatments

Packaging and Shipping

Your orders are carefully packaged to prevent damage during transit. We use protective materials and proper handling procedures to ensure your 1.2mm tantalum wire arrives in perfect condition. Standard packaging includes moisture protection and cushioning materials.

We work with reliable shipping partners to provide timely delivery worldwide, with tracking information provided for all shipments.

Why Choose Us

With over 30 years of experience in rare metals, we bring unmatched expertise to every project. Located in China's "Titanium Capital," we have access to premium raw materials and advanced manufacturing facilities. Our commitment to quality and customer satisfaction has earned us clients in over 50 countries.

We offer competitive pricing, reliable delivery, and exceptional customer service. When you choose us, you're partnering with a company that understands your needs and delivers solutions that exceed expectations.

|

|

|

|

|

|

FAQs

Q: Can tantalum wire be welded?

A: Yes, tantalum wire can be welded using appropriate techniques in inert atmospheres.

Q: What's the minimum order quantity?

A: We accommodate orders of various sizes, from small quantities for prototyping to large production runs.

Q: How should tantalum wire be stored?

A: Store in a clean, dry environment away from contaminating materials.

Contact Us

Ready to discuss your tantalum wire requirements? Our technical team is here to help you find the perfect solution. Contact us today at info@chdymetal.com to learn more about our products and capabilities. We look forward to supporting your next project with our premium 1.2mm tantalum wire solutions.

Learn about our latest products and discounts through SMS or email