- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

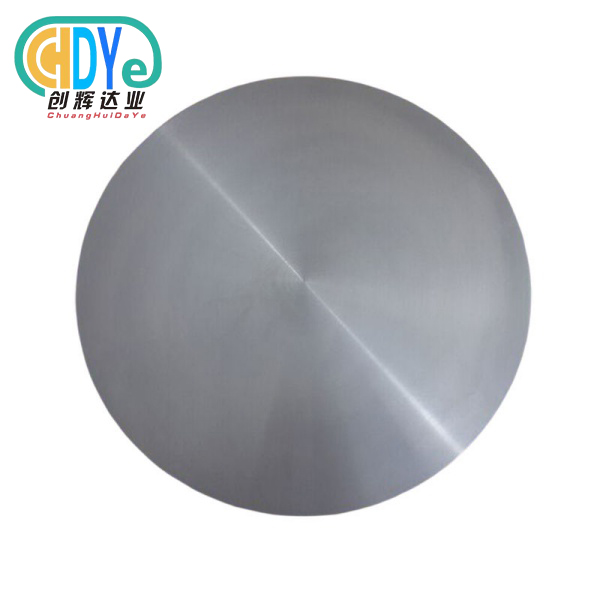

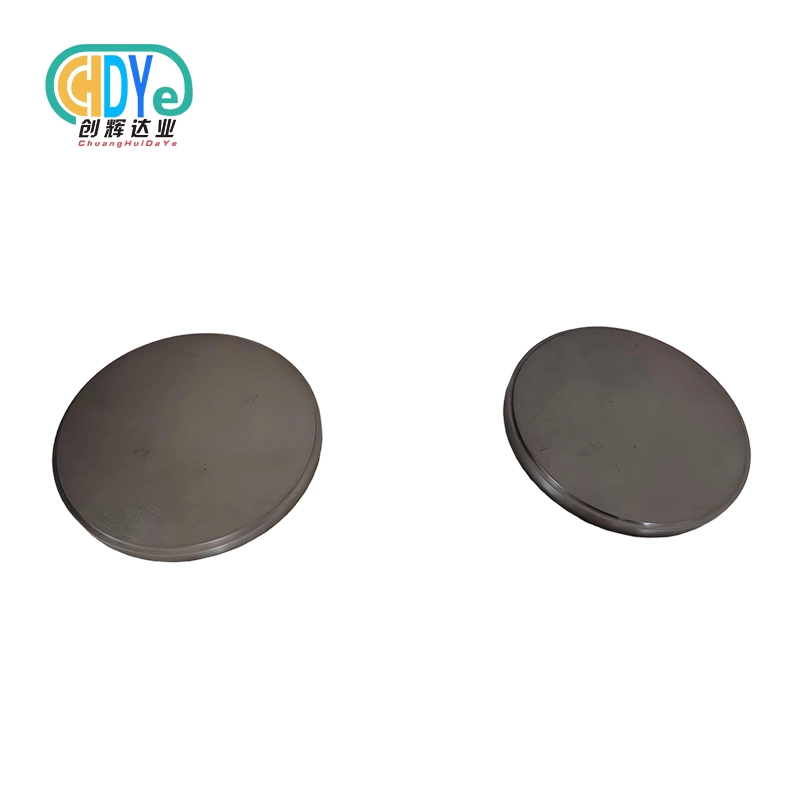

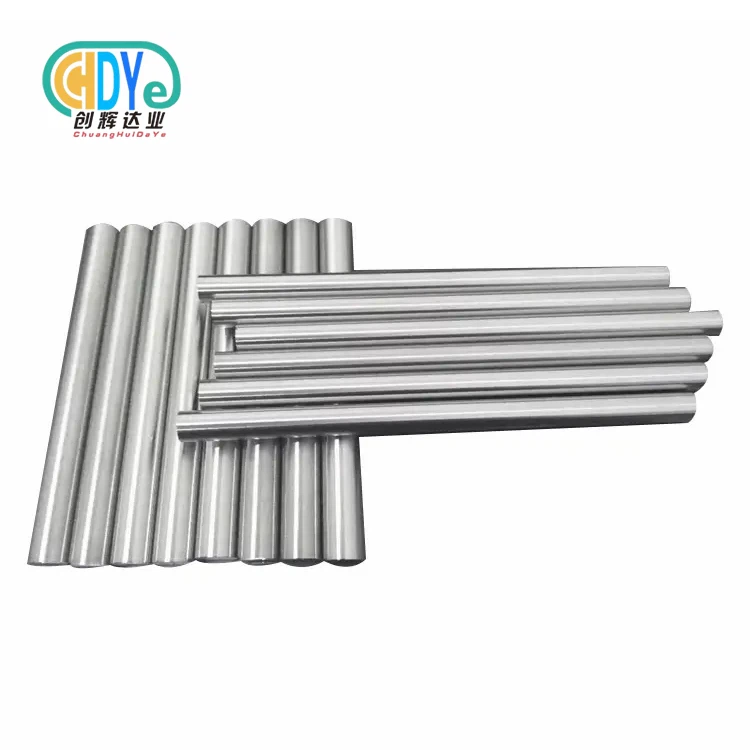

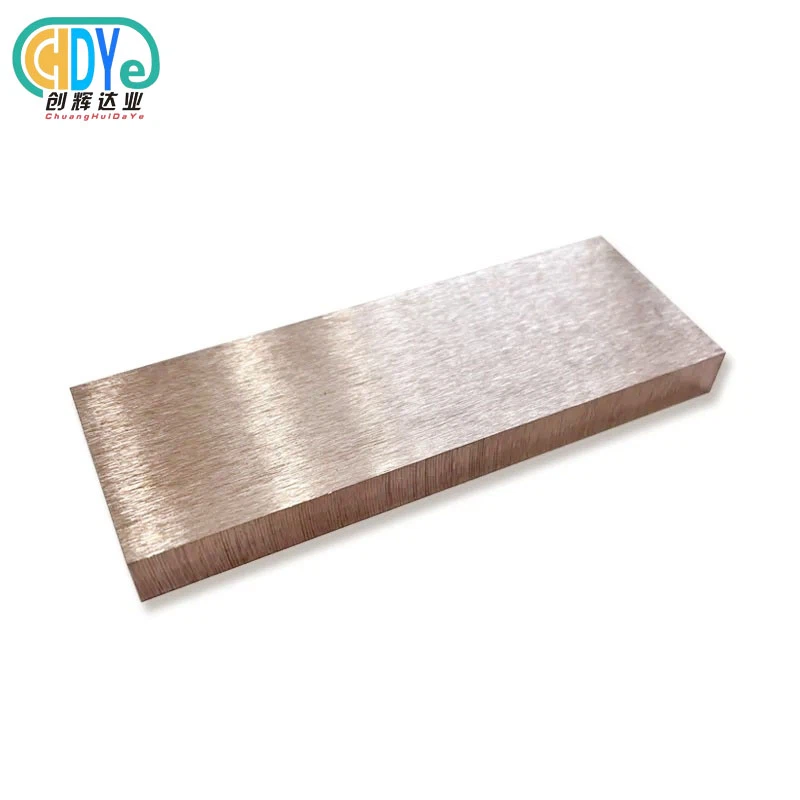

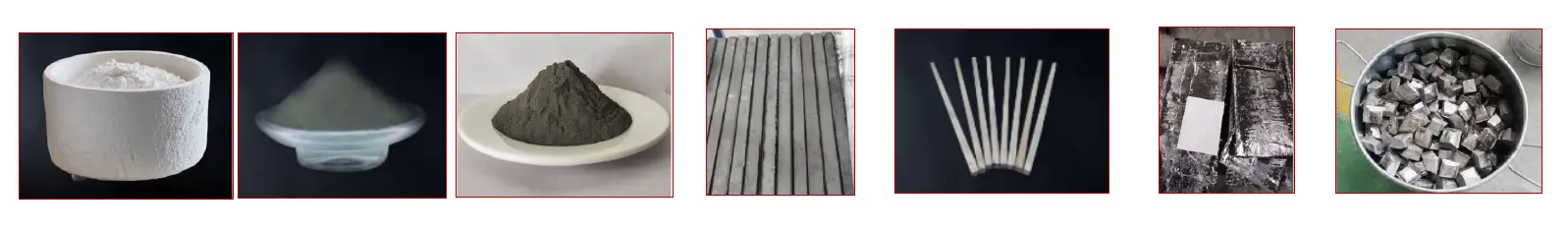

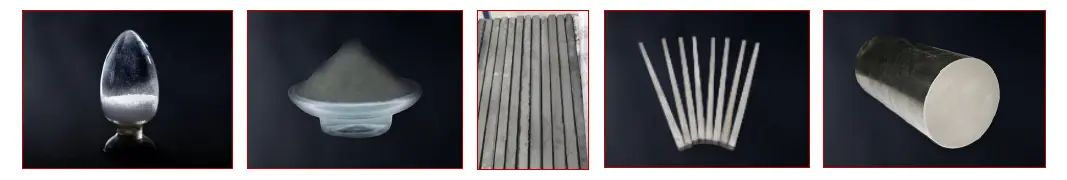

Tantalum Lump

2.Specifications: (17 × 17) ± 3 × 450 ± 50mm or customized

3.Packing : wooden box 50kg/ box

Product Introduction

Looking for high-quality Tantalum Lump for your industrial applications? You've come to the right place. Our premium tantalum lumps offer exceptional purity of 99.9% and are specifically designed for smelting and alloying processes. With a density of 16.65 g/cm³, these lumps ensure uniform melting and consistent performance in your manufacturing operations. Each piece meets strict quality standards, making our Tantalum Lump the ideal choice for demanding industrial applications.

Key Features and Benefits

Our tantalum lumps deliver outstanding performance across multiple applications:

- Superior Purity: 99.9% purity ensures optimal performance in critical applications

- High-Temperature Stability: Melting point of 3017°C supports extreme temperature operations

- Excellent Corrosion Resistance: Perfect for chemical processing environments

- Consistent Quality: Low oxygen content (≤120 ppm) maintains chemical stability

- Optimal Size Range: 20-100 mm lumps designed for industrial furnaces

- Low Contamination: Surface oxidation ≤2% reduces processing issues

Technical Specifications

Chemical composition

|

Nb |

O |

C |

N |

Fe |

Ni |

Cr |

Mn |

|

|

Standard value |

0.02 |

0.25 |

0.015 |

0.02 |

0.01 |

0.01 |

0.005 |

0.003 |

|

|

Si |

Ti |

Zr |

W |

Al |

Mo |

Cu |

- |

|

Standard value |

0.01 |

0.003 |

0.003 |

0.005 |

0.003 |

0.003 |

0.003 |

- |

Available Grades and Materials

We offer premium Ta-1 grade tantalum lumps that meet international quality standards. Our materials are carefully selected and processed to ensure consistent chemical composition and physical properties. Custom specifications are available upon request to meet your specific requirements.

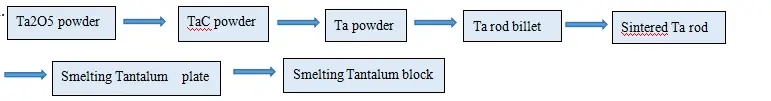

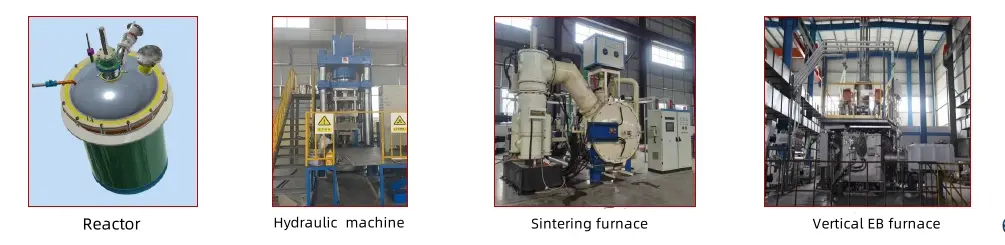

Manufacturing Process

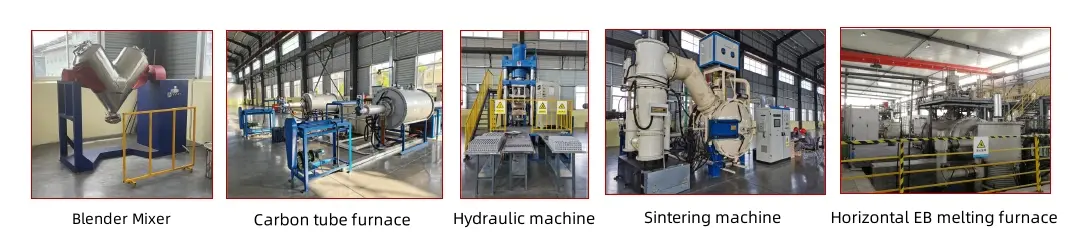

Our tantalum lumps are produced through advanced electron beam melting technology. This process involves:

- Raw material selection and purification

- Horizontal electron beam furnace melting

- Controlled cooling and solidification

- Quality inspection and testing

- Size sorting and packaging

This refined process ensures superior quality and eliminates impurities that could affect your final products.

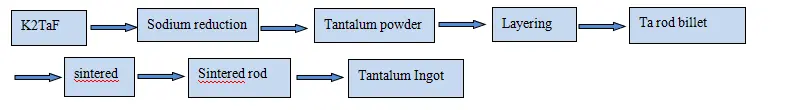

Two processes for producing tantalum blocks

Carbon reduction tantalum bar process flow C+Ta2O5( Nb2O5)→Ta(Nb)+CO ↑

Sodium reduction tantalum bar process flow (K2TaF7+5Na=Ta+5NaF+2KF )

Applications and Industries

Our Tantalum Lump serves various industrial sectors:

- Superalloy Production: Essential additive for high-temperature alloys

- Chemical Processing: Equipment manufacturing for corrosive environments

- Electronics Industry: Capacitor and semiconductor applications

- Aerospace: High-performance component manufacturing

- Medical Devices: Biocompatible implant production

- Metallurgy: Special steel and alloy enhancement

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

Standard dimensions: (17 × 17) ± 3 × 450 ± 50mm

Custom sizes available based on your specifications

Tight tolerances ensure consistent performance

Quality control maintains dimensional accuracy

Product Features in Detail

The exceptional properties of our tantalum lumps make them stand out:

High Melting Point Performance: With a melting point reaching 2996°C, our material excels in extreme temperature applications.

Outstanding Ductility: Easy forming during processing makes it suitable for various manufacturing processes.

Chemical Stability: Excellent resistance to acids and corrosive chemicals ensures long-lasting performance.

Quality Assurance and Testing

Every batch undergoes rigorous testing to ensure compliance with industry standards. Our quality control process includes chemical composition analysis, dimensional verification, and surface quality inspection. We maintain detailed certificates of analysis for traceability.

|

|

|

OEM & Customization Services

We understand that different applications require specific material properties. Our team works closely with you to develop customized solutions. Whether you need specific dimensions, purity levels, or packaging requirements, we can accommodate your needs.

Packaging and Shipping

- Standard Packaging: Wooden boxes (50kg per box)

- Protective Measures: Moisture-proof and contamination-free packaging

- Global Shipping: Reliable delivery to over 50 countries

- Secure Handling: Professional packaging ensures product integrity

Why Choose Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd. brings over 30 years of expertise in rare metal processing. Located in China's "Titanium Capital," we combine advanced technology with deep industry knowledge. Our commitment to quality, competitive pricing, and reliable delivery has earned trust from customers worldwide.

We focus on building long-term partnerships through excellent service and consistent product quality. Your success is our priority, and we're here to support your projects with premium materials and expert guidance.

|

|

|

|

|

|

FAQs

Q: What applications are best suited for your tantalum lumps?

A: Our products excel in superalloy production, chemical processing equipment, and high-temperature applications.

Q: Can you provide custom specifications?

A: Yes, we offer customization services to meet specific dimensional and purity requirements.

Q: What quality certifications do you provide?

A: We provide detailed certificates of analysis with each shipment, documenting chemical composition and physical properties.

Q: How do you ensure product quality during shipping?

A: We use professional packaging methods and work with reliable logistics partners to maintain product integrity.

Contact Us

Ready to enhance your projects with premium Tantalum Lump? Our experienced team is here to help you find the perfect solution for your specific needs. Whether you have technical questions or need a custom quote, we're just one email away.

Email: info@chdymetal.com

Let us be your trusted partner in rare metal materials. Contact us today to discuss how our high-quality tantalum lumps can benefit your operations.

Learn about our latest products and discounts through SMS or email