- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

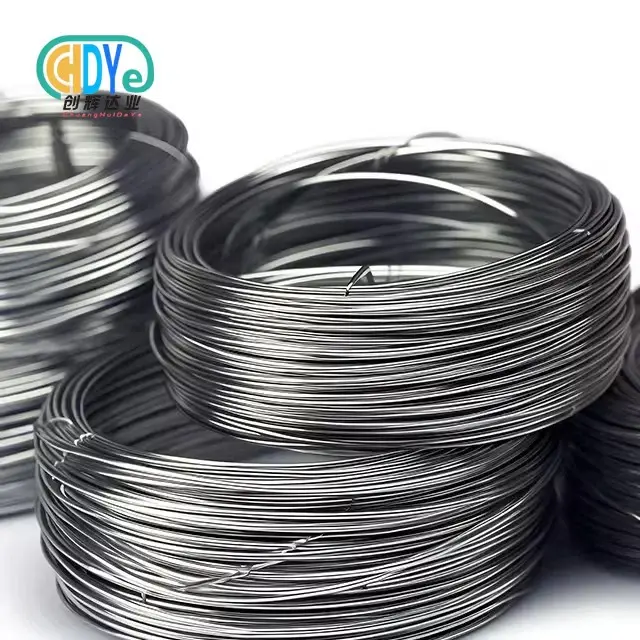

ASTM B863 Titanium Wire

2.Shape:Straight, in coil or spool

3.Standard: AWS A5.16, ASTM B863, ASTM F136

Product Overview

ASTM B863 Titanium Wire supplied by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is manufactured strictly in accordance with the ASTM B863 standard, which specifies the requirements for titanium and titanium alloy wire for industrial and aerospace applications.

Produced in Baoji, Shaanxi Province — China’s Titanium Capital, our titanium wire is engineered for precision, consistency, and long-term reliability. It offers outstanding corrosion resistance, excellent strength-to-weight ratio, and uniform metallurgical structure, making it a preferred choice for welding, chemical processing, aerospace, and medical industries.

Each wire undergoes vacuum melting, precision drawing, controlled annealing, and surface finishing, ensuring compliance with international standards such as ASTM B863, AMS 4951, ISO 9001:2015, and EN 10204 3.1.

Astm b863 Titanium wire is typically used in the chemical processing industry and anodized for hanging parts or components or when an item requires being tied down.

Shape: Straight, in coil or spool

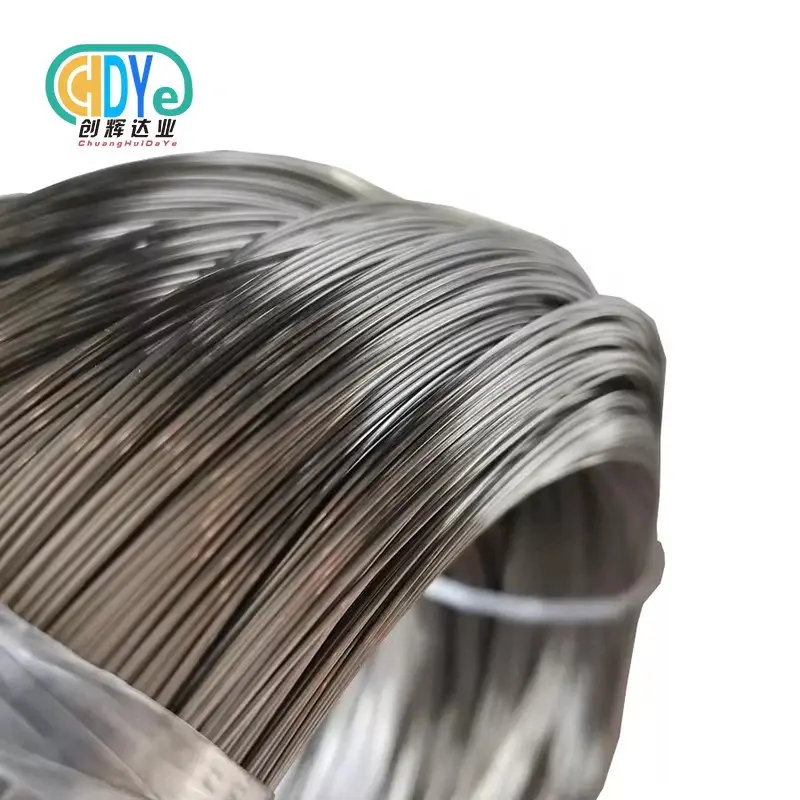

Surface Treatment: Polished, Pickled

Specifications:

Standard: AWS A5.16, ASTM B863, ASTM F136

Size: From 0.15 - 7mm

Grades:

Grade 5 Ti-6Al-4V

Grade 7 Ti-0.2Pd

Grade 9 Ti-3Al-2.5V

Grade 12 Ti-0.3Mo-0.8Ni

Grade 23 Ti-6Al-4V ELI

Technical Specifications

| Parameter | Specification |

|---|---|

| Standard | ASTM B863 |

| Material Grades | Gr1, Gr2, Gr3, Gr4, Gr5 (Ti-6Al-4V), Gr7 |

| Diameter Range | 0.2 mm – 6.0 mm |

| Surface Condition | Pickled, Polished, Bright Annealed, Oxide-free |

| Tensile Strength | 240 MPa – 895 MPa (grade-dependent) |

| Elongation | 20% – 35% |

| Density | 4.51 g/cm³ |

| Straightness | ≤ 0.2 mm/m |

| Melting Point | 1668°C |

| Form of Supply | Coil, Spool, Straight-cut, or Customized |

| Certification | ISO 9001:2015, SGS, EN 10204 3.1 |

Conformance to ASTM B863

ASTM B863 defines the chemical composition, mechanical properties, and dimensional tolerances of titanium wire.

Our manufacturing strictly adheres to all ASTM B863 provisions:

-

Chemical Composition: Verified using ICP-OES and spectrochemical analysis

-

Mechanical Testing: Tensile, yield, and elongation per section 10 of ASTM B863

-

Dimensional Inspection: Laser-controlled measurement within ±0.01 mm tolerance

-

Surface Condition: Smooth, oxide-free, and free of cracks or foreign inclusions

-

Microstructure: Uniform, equiaxed grain for stable mechanical behavior

Compliance ensures traceable, standardized, and globally accepted titanium wire quality for both OEM and engineering applications.

Mechanical & Surface Properties

| Property | Typical Value |

|---|---|

| Ultimate Tensile Strength (Gr2) | ≥ 345 MPa |

| Elongation (Gr2) | ≥ 25% |

| Yield Strength (Gr2) | ≥ 275 MPa |

| Hardness (Gr2) | 160 HV Max |

| Electrical Conductivity | 3.2% IACS |

| Surface Roughness (Ra) | ≤ 0.8 µm |

| Tolerance | ±0.01 mm |

Key Advantages:

- Stable mechanical behavior under repeated stress

- High fatigue resistance in cyclic loading environments

- Bright, smooth surface ideal for welding and electrochemical applications

- Low magnetism and excellent corrosion resistance in chloride and acidic conditions

Product Advantages

-

Certified ASTM B863 Standard Compliance: Guaranteed material traceability and mechanical reliability.

-

Multi-Grade Options: From high ductility Gr1 to high strength Gr5 (Ti6Al4V).

-

Uniform Diameter & Finish: Controlled through CNC drawing and continuous annealing.

-

Excellent Weldability: Ideal filler or component wire for precision welding systems.

-

High-Temperature Stability: Maintains structural integrity up to 600°C.

-

Corrosion Resistance: Performs well in nitric acid, seawater, and alkaline media.

-

Custom Manufacturing: Wire can be coiled, spooled, or straightened according to customer process.

Titanium wire types

Manufacturing & Process Flow

- Raw Material Inspection: All titanium sponge analyzed for purity before melting.

- Vacuum Melting (VAR or EBM): Ensures high-purity ingot with uniform microstructure.

- Forging and Rolling: Converts ingot to billet and rod with fine, consistent grain.

- Cold Drawing: Multi-pass wire drawing enhances strength and dimensional accuracy.

- Annealing: Performed under vacuum to optimize ductility and relieve stress.

- Surface Treatment: Polishing or acid pickling removes oxidation and imperfections.

- Straightening / Coiling: Configured based on buyer’s application (straight cut or spool).

- Testing & Certification: Each batch tested and issued a full MTC (Material Test Certificate).

This controlled process guarantees excellent consistency, mechanical integrity, and visual quality across all batches.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality assurance is a cornerstone of our production. Every order is tested according to international standards:

-

ISO 9001:2015 Certified Production System

-

Third-Party Testing (SGS / TUV) Available

-

Mechanical & Dimensional Inspection Before Shipment

-

Surface Visual Check: No cracks, burrs, or inclusions

-

Batch Traceability: From titanium sponge to final shipment

-

Documentation: EN 10204 3.1 Certificates issued with every delivery

Strict adherence to ASTM B863 ensures mechanical reliability, purity consistency, and international approval.

Application Advantages

Aerospace: Control cables, spring wire, and fasteners exposed to extreme temperature and corrosion.

Chemical Engineering: Electrodes, heat exchanger elements, and chemical-resistant meshes.

Medical & Dental: Biocompatible surgical instruments, guide wires, and orthopedic pins.

Marine Engineering: Anti-corrosion reinforcement and sensor leads for subsea systems.

Electronics: Anode wires, connectors, and vacuum component feedthroughs.

Additive Manufacturing: Used as precision feedstock for 3D printing and powder synthesis.

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

R&D and Customization

- Customized mechanical strength and elongation through controlled annealing

- Tailored coil or straight length for automated production lines

- Surface finish customization: pickled, mirror-polished, or bright annealed

- OEM packaging, logo, and labeling for international distributors

- Prototype development for advanced alloys and new applications

Our R&D team continuously works with aerospace, chemical, and medical sectors to optimize titanium wire performance and cost-efficiency.

Packaging & Global Logistics

To ensure the titanium wire arrives in perfect condition:

- Inner Layer: PE moisture-proof wrapping or vacuum sealing

- Intermediate Layer: Foam padding to prevent deformation

- Outer Package: Wooden case or reinforced export carton

- Marking: Includes alloy grade, standard (ASTM B863), batch number, and net weight

- Shipping Options: Air freight, sea shipment, or international express

We cooperate with international logistics partners to guarantee safe and on-time global delivery.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

Global Partnership & Case References

Shaanxi Chuanghui Daye has established long-term partnerships in over 50 countries, serving clients across aerospace, petrochemical, and medical industries.

- Europe: Titanium wire for welding and heat exchanger fabrication.

- North America: Certified ASTM B863 titanium alloy wire for precision components.

- Asia-Pacific: Supply for electrochemical and marine equipment producers.

- Middle East: Long-term cooperation with refineries and corrosion control systems.

Our commitment to standardized quality, professional service, and reliable delivery has earned strong trust from international buyers.

Why Choose Us

- Over 30 years of rare metal production experience

- Fully compliant with ASTM, AMS, ISO, and GB standards

- Advanced vacuum melting and drawing facilities

- Fast 7–10 day delivery for standard wire specifications

- OEM/ODM manufacturing available for global partners

- Full inspection & certification with every shipment

- Responsive technical support from experienced engineers

We focus on precision, purity, and partnership — ensuring our clients receive top-quality titanium wire with unmatched reliability.

|

|

|

|

|

|

FAQ

Q1: What is the main difference between ASTM B863 and other titanium wire standards?

ASTM B863 provides the global specification for industrial-grade and alloy titanium wire, focusing on mechanical and chemical consistency.

Q2: Can you supply both titanium and titanium alloy wire under ASTM B863?

Yes, we provide grades Gr1 through Gr7, including Ti-6Al-4V (Gr5) and Ti-0.2Pd (Gr7).

Q3: How do you ensure batch consistency?

All production batches are recorded with individual heat numbers and MTC documentation.

Q4: Can you customize wire length and packaging?

Yes, we can supply straight lengths or spools with custom labeling and export packaging.

Q5: Do you provide third-party inspection before shipment?

Absolutely. SGS, BV, or TUV inspection can be arranged based on buyer requirements.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email

_1760923994993.jpg)