- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

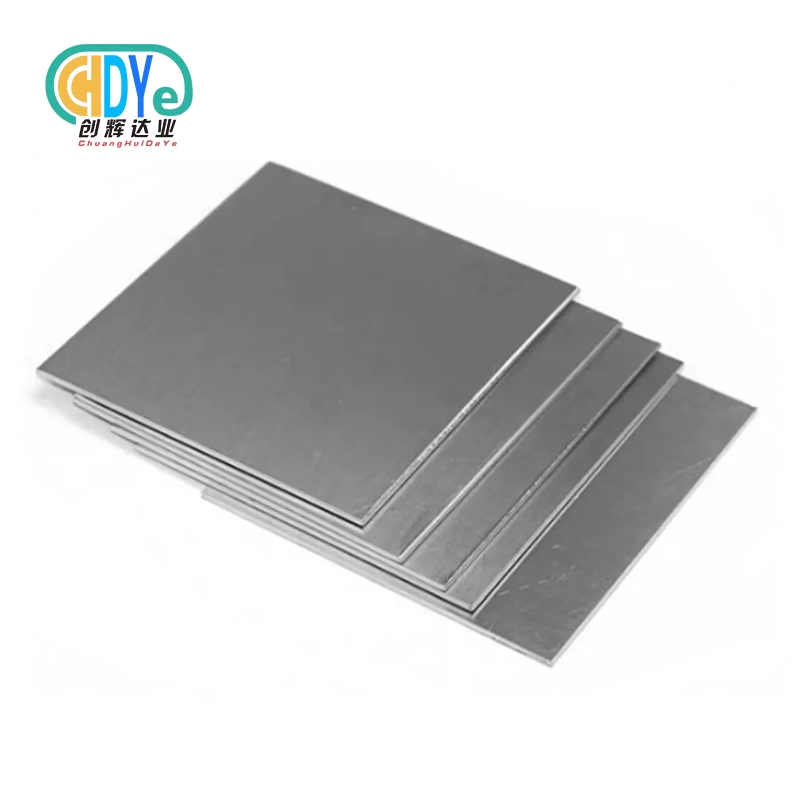

niobium sputter targets

Purity 99.9% guarantees uniform optical films

Thickness 4–20 mm compatible with magnetron systems

Residual stress ≤35 MPa prevents cracking

Product Introduction

Looking for high-performance niobium sputter targets for your thin film applications? You've come to the right place. Our premium niobium targets deliver exceptional coating quality with 99.9% purity and consistent performance. Whether you need materials for semiconductor manufacturing, optical coatings, or research applications, our niobium sputter targets provide the reliability and precision your projects demand. With over 30 years of expertise in rare metals, we understand exactly what you need for successful sputtering operations.

Key Features and Benefits

Our niobium targets offer outstanding performance characteristics that make them ideal for demanding applications:

• Superior Purity: 99.9% minimum purity ensures clean, contamination-free coatings

• Excellent Uniformity: ≥98% uniformity index delivers consistent film thickness across your substrate

• High Temperature Stability: Withstands extreme conditions with a melting point of 2477°C

• Low Stress Design: Residual stress ≤35 MPa prevents target cracking during operation

• Corrosion Resistance: Outstanding chemical stability for long-lasting performance

• Precise Dimensions: Custom sizes available to fit your specific sputtering equipment

Technical Specifications

|

Product name |

Niobium sputter targets |

|

Purity |

Nb ≥99.95% |

|

Grade |

R04200, R04210, Nb-50Ti etc |

|

Shape |

target, bar, ingot etc. |

|

Size |

Customized size |

|

Melting point |

2468℃ |

|

Boiling point |

4742℃ |

|

Advantage |

♦ Low Density and High Specificate Strength |

|

♦ Excellent Corrosion Resistance |

|

|

♦ Good resistance to effect of heat |

|

|

♦ Nonmagnetic and Non-toxic |

|

|

♦ High melting point, good anti-corrosion, excellent super-conduction and other unique characteristics. |

|

|

Application |

♦ Electronic industry, Chemistry, Electronical, Pharmaceutical industry. |

|

♦ Steel, Ceramics, Electronics, nuclear energy industries and superconductor technology. |

|

|

♦ Super condouctous, metled cast ingots and alloying agents. |

|

|

♦ Widely used in manufacturing various kinds of alloy steel, high temperature alloy, optical glass, cutting tool, superconducting |

Available Grades and Materials

We supply niobium targets in various grades to meet your specific requirements:

• R04200 Grade: Standard commercial purity for general applications

• R04210 Grade: Enhanced purity for specialized thin film requirements

• Custom Alloys: Niobium-based alloys available upon request

• Backing Options: Copper, titanium, or molybdenum backing plates available

Manufacturing Process

Our advanced manufacturing process ensures consistent quality and performance. We start with high-purity niobium raw materials and use precision machining techniques. Each target undergoes careful heat treatment to optimize grain structure and eliminate internal stresses. Our quality control team monitors every step to guarantee your targets meet exact specifications.

|

|

|

|

|

|

|

|

Applications and Industries

Niobium sputter targets serve critical roles across multiple industries:

Semiconductor Manufacturing: Gate electrodes, barrier layers, and interconnects for advanced microprocessors and memory devices.

Optical Coatings: Anti-reflective coatings, mirrors, and filters for telecommunications and laser systems.

Medical Devices: Biocompatible coatings for implants and surgical instruments due to excellent corrosion resistance.

Solar Energy: Thin film photovoltaic cells and energy storage applications.

Research & Development: Laboratory-scale coating experiments and materials research projects.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Features in Detail

Your coating success depends on target quality. Our products feature cold-rolled surfaces for optimal sputtering performance and machined surfaces when required. The controlled grain structure ensures uniform erosion patterns and extends target life. Low hydrogen content prevents porosity in your films, while excellent bonding strength eliminates delamination risks.

Quality Assurance and Testing

Every target undergoes comprehensive testing before shipment. We verify chemical composition, dimensional accuracy, and surface quality. Our testing includes density measurements, purity analysis, and mechanical property evaluation. You receive detailed certificates of analysis with each order, ensuring complete traceability and quality documentation.

|

|

|

OEM & Customization Services

Need something specific? We excel at custom solutions. Our engineering team works with you to develop targets that match your exact requirements. Whether you need special dimensions, unique backing configurations, or modified compositions, we deliver precisely what your application demands.

Packaging and Shipping

Your targets arrive safely packaged in protective containers designed to prevent damage during transit. We use moisture-resistant packaging and provide detailed handling instructions. Our logistics team coordinates worldwide shipping to ensure timely delivery to your facility.

Why Choose Us

With three decades of rare metal expertise, we understand your challenges. Located in China's "Titanium Capital," we combine advanced technology with competitive pricing. Our products serve customers in over 50 countries, proving our commitment to quality and reliability. When you choose our niobium sputter targets, you're partnering with industry experts who put your success first.

|

|

|

|

|

|

FAQs

Q: What backing materials do you recommend?

A: Copper backing works well for most applications, while titanium backing suits high-temperature processes.

Q: Can you provide targets for research quantities?

A: Yes, we supply everything from small research samples to large production quantities.

Q: What's your typical lead time?

A: Standard products ship within 2-3 weeks, while custom orders typically require 4-6 weeks.

Contact Us

Ready to discuss your niobium sputter targets requirements? Our technical team is here to help you select the perfect solution for your application. Contact us today at info@chdymetal.com to request quotes, technical specifications, or application guidance. We look forward to supporting your next project with our premium quality products and exceptional service.

Learn about our latest products and discounts through SMS or email