- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

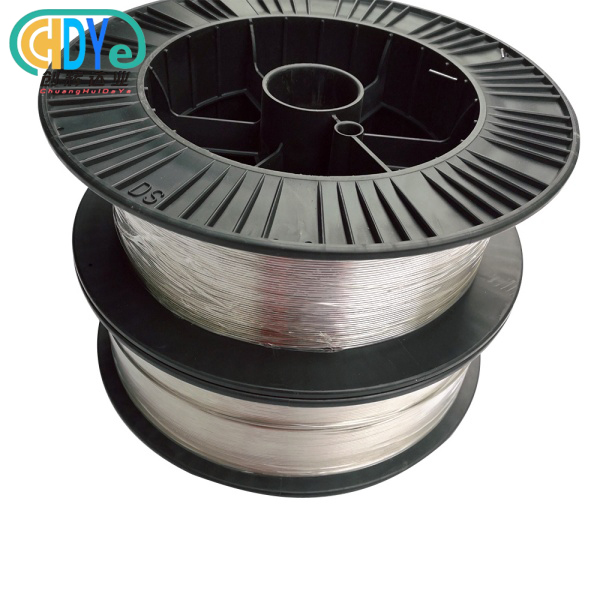

molybdenum cutting wire

2. Diameter: 0.05–1 mm

3. Length: as your request

4. Tensile strength: 500–700 MPa

5. Density: 10.2 g/cm³

6. Applications: EDM, cutting

7. Heat resistant

Product Introduction

When you need exceptional precision for your electrical discharge machining (EDM) applications, our molybdenum cutting wire delivers unmatched performance and reliability. Manufactured with over 99.95% pure molybdenum, this premium wire offers superior tensile strength and thermal stability for demanding cutting operations. Our cutting wire provides excellent surface finish and dimensional accuracy, making it your ideal choice for precision manufacturing. With decades of experience in refractory metals, we understand what you need for successful EDM operations.

Key Features and Benefits

Our molybdenum wire stands out with remarkable tensile strength of 1724 N/mm², significantly higher than copper or brass alternatives. You'll experience fewer wire breaks and better cutting accuracy. The exceptional thermal resistance ensures consistent performance even under high-temperature conditions. Your cutting operations benefit from minimal wire elongation and superior straightness control.

Technical Specifications

| Property | Value |

|---|---|

| Purity | Mo >99.95% |

| Diameter Range | 0.08–3mm |

| Standard Diameter | 0.18mm (±0.003mm) |

| Maximum Length | 1000 mm |

| Tensile Strength | 500–700 MPa |

| Density | 10.2 g/cm³ |

| Elongation | <2% |

| Operating Temperature | Up to 2000°C |

| Standard | ASTM B387-10, |

| Certificate | ISO 9001:2015 |

| Scope of application | Heating elements, high-temperature components, wire cutting, etc. |

Chemical composition

|

|

Mo |

W |

Al |

Ca |

Fe |

Mg |

Ni |

Si |

C |

N |

O |

|

Mo1 |

balance |

0.001 |

0.002 |

0.002 |

0.01 |

0.002 |

0.005 |

0.01 |

0.01 |

0.003 |

0.008 |

|

Mo2 |

balance |

0.001 |

0.005 |

0.004 |

0.015 |

0.005 |

0.005 |

0.01 |

0.02 |

0.003 |

0.01 |

Available Grades and Materials

We offer pure molybdenum grades specifically designed for EDM applications. Our standard grade provides excellent balance between cutting speed and wire life. For specialized applications requiring enhanced performance, we can customize material compositions to meet your specific requirements.

Manufacturing Process

Our molybdenum cutting wire begins with high-purity metal powder. We press this powder into ingots, then draw them through precision dies to achieve your desired diameter. Multiple annealing steps ensure optimal mechanical properties. Quality control testing occurs at every stage to guarantee consistent performance.

|

|

|

|

|

|

|

|

Applications and Industries

Your industries benefit from our wire's versatility. Aerospace components require precision cuts with zero contamination. Medical device manufacturing demands clean, accurate cutting. Electronics industry applications need fine detail work. Automotive tooling operations rely on our wire's strength and accuracy.

Be used in a wide range of industries.

Steel industry

Electronic devices

Furnace components

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

Standard diameter tolerance maintains ±0.003mm accuracy. Length specifications can be customized from 100mm to 1000mm. Surface finish meets Ra 0.8μm standards. Straightness deviation stays within 0.1mm per meter.

Product Features in Detail

The high tensile strength provides exceptional resistance to breaking during operation. You'll notice improved cutting speeds due to higher possible tension settings. Corner cutting accuracy improves significantly compared to softer wire materials. Surface contamination concerns disappear with our pure composition.

Quality Assurance and Testing

Every batch undergoes comprehensive testing including tensile strength verification, dimensional inspection, and purity analysis. We maintain strict quality standards throughout production. Documentation accompanies each shipment for your quality records.

|

|

|

OEM & Customization Services

We welcome custom diameter requirements and special length specifications. Your unique applications may need modified mechanical properties, which we can accommodate. Large volume orders receive priority scheduling and competitive pricing.

Packaging and Shipping

Professional packaging protects your molybdenum cutting wire during transit. Moisture-resistant containers maintain wire quality. We ship worldwide with reliable carriers. Tracking information keeps you informed of delivery status.

Why Choose Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd. brings over 30 years of refractory metals expertise. Our location in China's "Titanium Capital" provides access to premium raw materials. We serve customers in 50+ countries with consistent quality and competitive pricing.

|

|

|

|

|

|

FAQs

Q: What makes molybdenum better than brass wire?

A: Molybdenum cutting wire offers three times higher tensile strength, resulting in fewer breaks and straighter cuts.

Q: Can you customize wire diameters?

A: Yes, we produce custom diameters from 0.05mm to 1mm based on your specifications.

Q: What's the typical lead time?

A: Standard products ship within 7-10 days. Custom orders require 15-20 days.

Contact Us

Ready to improve your EDM operations? Contact us for detailed specifications, pricing, and technical support. We're here to help you achieve superior cutting results with our premium molybdenum solutions.

E-mail: info@chdymetal.com

Mob.:86-18049386902

Learn about our latest products and discounts through SMS or email