- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

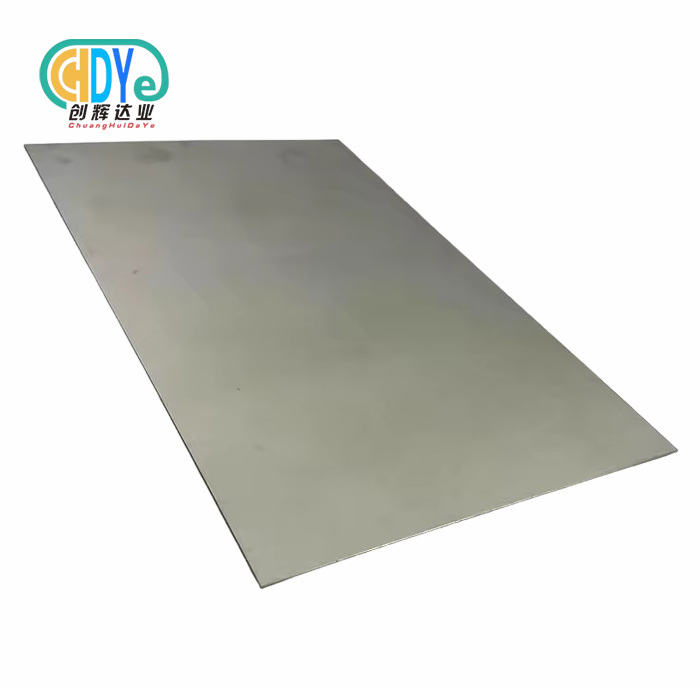

tantalum alloy sheet plate

2.Size: Thickness 0.5-20mm*width50-1200*Length30-2500mm

3.Standard: ASTM B708

4.Delivery: stock size will arrange within 1-3 days, normal production time about 15 working day.

Product Introduction

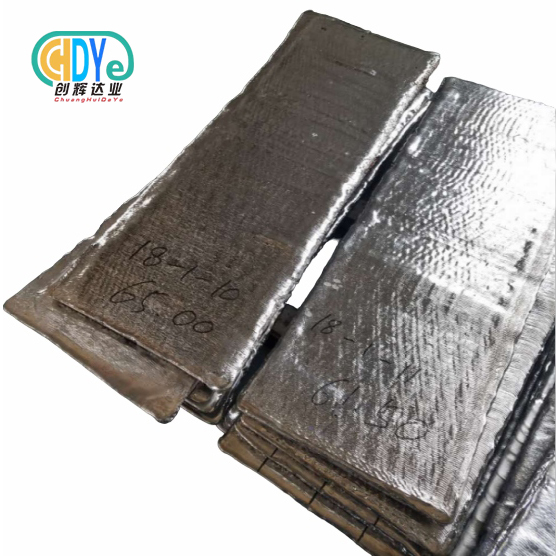

Looking for exceptional corrosion resistance and high-temperature performance? Our tantalum alloy sheet plate delivers outstanding reliability for your most demanding applications. At Shaanxi Chuanghui Daye Metal Material Co., Ltd., we combine over 30 years of rare metal expertise with advanced manufacturing processes. Located in China's "Titanium Capital," we produce premium-quality tantalum alloy products that meet international standards. Our sheets offer superior strength, excellent ductility, and remarkable chemical resistance for aerospace, chemical processing, and medical industries.

Key Features and Benefits

- Exceptional Corrosion Resistance: Withstands aggressive acids and chemicals

- High-Temperature Stability: Maintains properties at extreme temperatures

- Superior Strength: Enhanced mechanical properties through alloying

- Excellent Ductility: Easy to form and fabricate

- Chemical Inertness: Perfect for medical and food processing applications

- Long Service Life: Reduces maintenance costs and downtime

Technical Specifications

|

Product Name |

tantalum alloy sheet plate |

|

Purity |

99.95% min |

|

Standard |

ASTM B708 |

|

Size |

Thickness 0.5-20mm*width50-1200*Length30-2500mm |

|

Condition |

1.Hot-rolled/Cold-rolled; 2.Alkaline Cleaning |

|

Customized products |

According to drawing, Special requirements to be agreed upon by the supplier and buyer. |

| Certificate | ISO 9001:2015 |

| Delivery time | Normal production time need about 10-15 working days |

| Payment terms | 30%TT in advance, 70% balance payment before shipment |

Available Grades and Materials

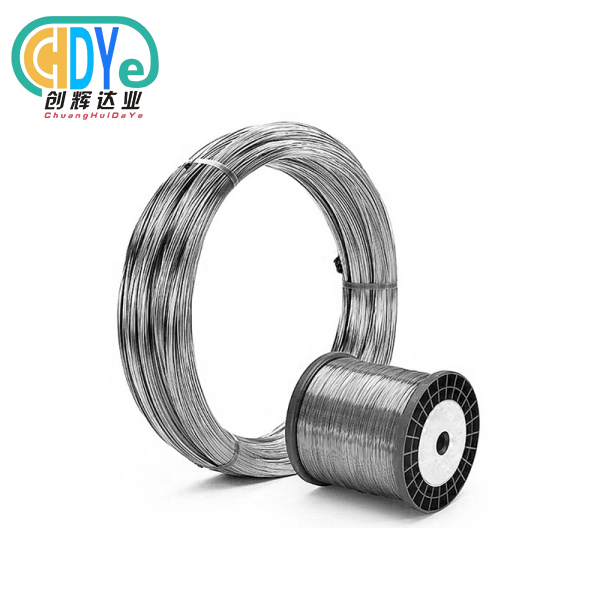

Ta-Nb Alloys: Enhanced ductility and corrosion resistance

- Ta-2.5%Nb: Standard grade for chemical processing

- Ta-10%Nb: High-strength applications

Ta-W Alloys: Superior high-temperature performance

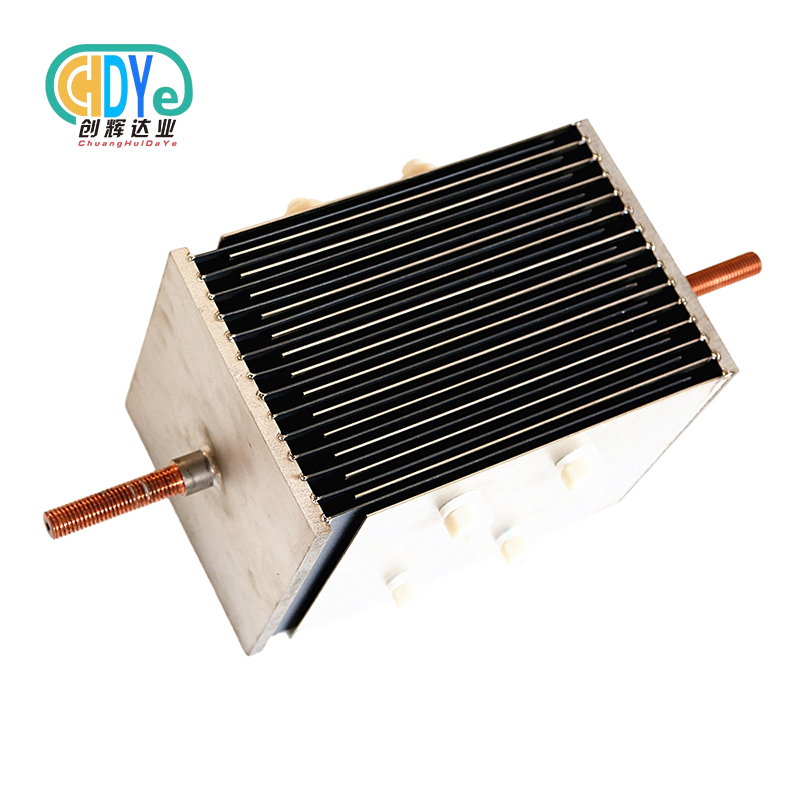

- Ta-2.5%W: Heat exchanger applications

- Ta-10%W: Aerospace and defense uses

Chemical composition

|

Content, Max, Weight % |

||||

|

Element |

R05200 Uanlloyed Tantalum |

R05255 90% Tantalum 10% Tungsten |

R05252 97.5% Tantalum 2.5% Tungsten |

R05240 60% Tantalum 40% Niobium |

|

C |

0.010 |

0.010 |

0.010 |

0.010 |

|

O |

0.015 |

0.015 |

0.015 |

0.020 |

|

N |

0.010 |

0.010 |

0.010 |

0.010 |

|

H |

0.0015 |

0.0015 |

0.0015 |

0.0015 |

|

Fe |

0.010 |

0.010 |

0.010 |

0.010 |

|

Mo |

0.020 |

0.020 |

0.020 |

0.020 |

|

Nb |

0.100 |

0.100 |

0.50 |

35.0~42.0 |

|

Ni |

0.010 |

0.010 |

0.010 |

0.010 |

|

Si |

0.005 |

0.005 |

0.005 |

0.005 |

|

Ti |

0.010 |

0.010 |

0.010 |

0.010 |

|

W |

0.05 |

9.1~11.0 |

2.0~3.5 |

0.050 |

|

Ta |

Remainder |

Remainder |

Remainder |

Remainder |

Manufacturing Process

Our advanced production process ensures consistent quality:

- Raw Material Selection: Premium-grade tantalum and alloying elements

- Vacuum Melting: Eliminates impurities and ensures homogeneity

- Hot Rolling: Achieves desired thickness and mechanical properties

- Annealing: Optimizes grain structure and ductility

- Cold Rolling: Precise dimensional control

- Quality Testing: Comprehensive inspection at every stage

|

|

|

|

|

|

|

|

Applications and Industries

Chemical Processing: Reaction vessels, heat exchangers, and piping systems

Aerospace: Engine components, structural elements, and heat shields

Medical Devices: Implants, surgical instruments, and diagnostic equipment

Electronics: Capacitors, sputtering targets, and semiconductor components

Nuclear Industry: Reactor components and radiation shielding

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

- Thickness Tolerance: ±0.05mm for sheets under 5mm

- Width Tolerance: ±2mm standard, ±1mm precision available

- Length Tolerance: ±5mm standard

- Flatness: Within 2mm per meter

- Surface Finish: Ra 0.8μm standard, finer finishes available

Product Features in Detail

Our tantalum alloy sheet plate combines pure tantalum's beneficial properties with enhanced performance through strategic alloying. The addition of niobium improves ductility and formability, while tungsten increases strength and temperature resistance. Each sheet undergoes controlled processing to achieve optimal grain structure and mechanical properties for your specific application requirements.

Quality Assurance and Testing

Every product undergoes rigorous testing:

- Chemical Composition Analysis: ICP-OES verification

- Mechanical Testing: Tensile strength and elongation tests

- Dimensional Inspection: Precision measurement equipment

- Surface Quality Check: Visual and automated inspection

- Certification: Material certificates provided with each shipment

OEM & Customization Services

We provide tailored solutions for your unique requirements:

- Custom dimensions and tolerances

- Specific alloy compositions

- Special surface treatments

- Precision cutting and shaping

- Engineering consultation and support

Packaging and Shipping

Packaging: Individual sheets wrapped in protective film, wooden crates for international shipping

Shipping Options: Air freight for urgent orders, sea freight for standard delivery

Documentation: Complete export documentation and material certificates

Delivery Time: 2-4 weeks for standard specifications

Why Choose Us

With over three decades of rare metal experience, we understand your challenges. Our location in Baoji's high-tech zone provides access to advanced facilities and skilled technicians. We've successfully supplied customers across 50+ countries, building lasting partnerships through quality products and reliable service. Our commitment to continuous improvement ensures you receive the best possible solutions.

|

|

|

|

|

|

FAQs

Q: What's the minimum order quantity?

A: We accommodate orders from 10kg, with flexible quantities for custom specifications.

Q: Can you provide material certificates?

A: Yes, comprehensive certificates including chemical composition and mechanical properties accompany every shipment.

Q: Do you offer technical support?

A: Our experienced engineers provide application guidance and technical consultation throughout your project.

Q: What payment terms do you accept?

A: We accept T/T, L/C, and other standard international payment methods.

Contact Us

Ready to discuss your tantalum alloy sheet plate requirements? Our technical team is standing by to help you select the perfect material for your application. Contact us today for quotations, technical specifications, or engineering support.

Email: info@chdymetal.com

Mob./what's app.: 86-18049386902

Let us be your trusted partner for high-quality rare metal solutions. Experience the difference that expertise and commitment make in your next project.

Learn about our latest products and discounts through SMS or email