- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium Anode Assembly

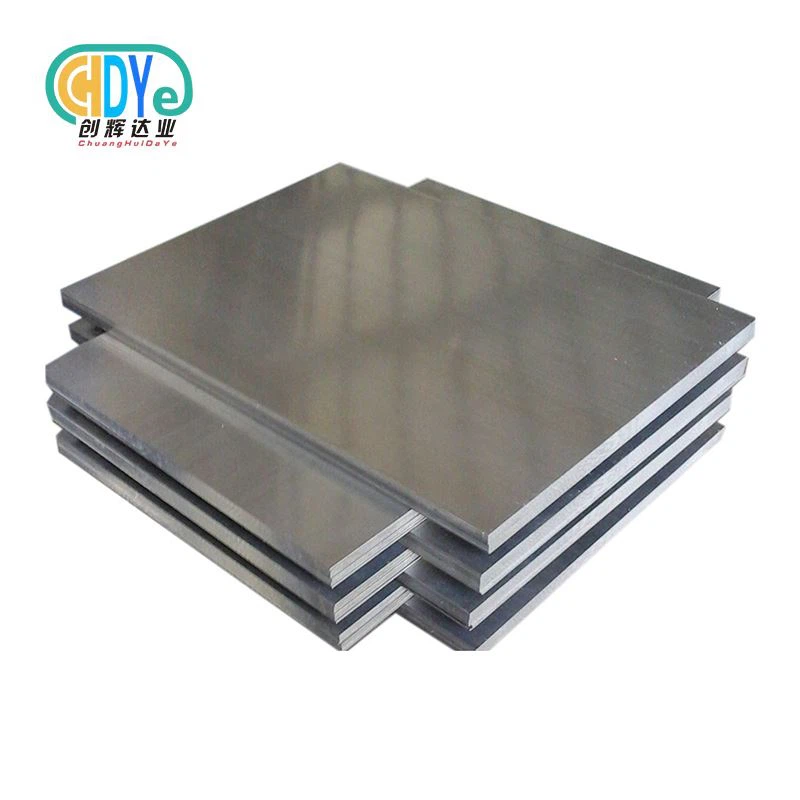

Substrate:Titanium Gr1, Gr2

Coating Type:Mixed Ruthenium-Iridium oxide, Ir-ta , platinum as coating

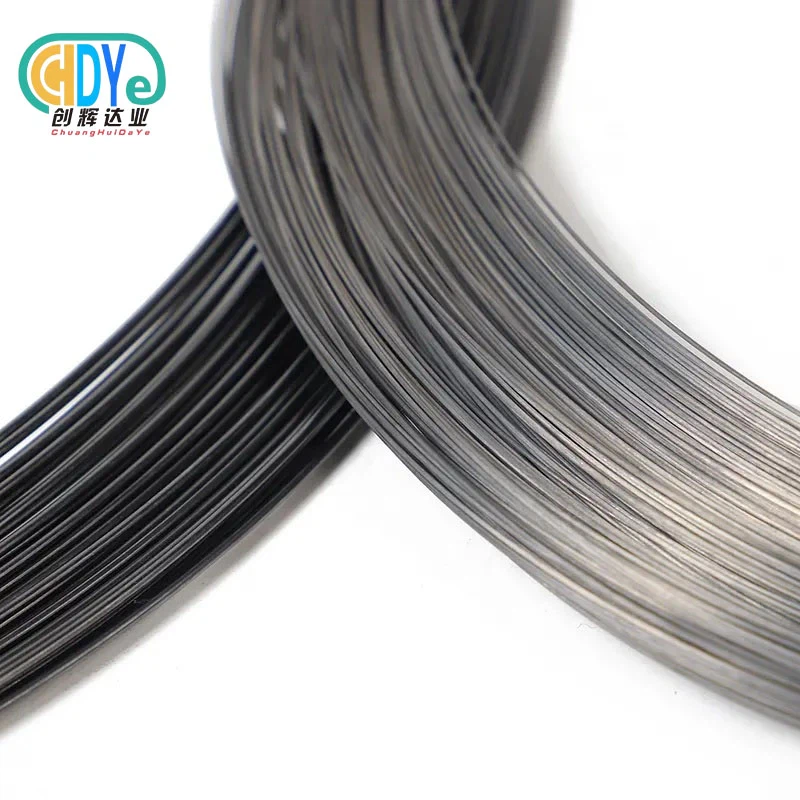

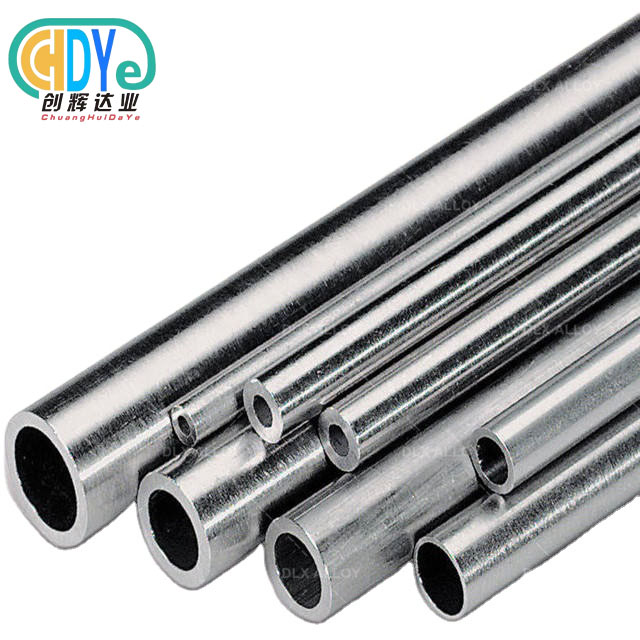

Shape:Plate/Mesh/Tube/Rod/Wire/Disc or Customized as the design drawing

Product Introduction

Chdymetal can provide various titanium anodes assembly, customized is accepted. titanium anode use pure titanium material as substrate, has high anti-corrosion and high catalytic activity. titanium anode assembly has long working life. For the important, the substrate could be reused.

|

Substrate |

Titanium Gr1, Gr2 |

|

Coating Type |

Mixed Ruthenium-Iridium oxide, Ir-ta , Ru-ir-Sn, platinum as coating |

|

Shape |

Plate/Mesh/Tube/Rod/Wire/Disc or Customized as the design drawing |

|

Technology |

Sand blasting, Acid Washing, Coating Brushing, High Temperature Sintering, Annealing |

|

Working |

1. Current density≤2000A/M2 (sodium hypochlorite)≤500A/M2 (sodium chlorate) |

|

Application |

1. Sewage Treatment |

|

Remark |

1. Titanium anode also called MMO anode,DSA & Insoluble anode |

Invention and development of anode is a key technology breakthrough in the application of seawater electrolysis. One of the well-known application is to prevent Mussels and algae growing on the ship hull and on the water cooling system for the power plant.

It is variant that electrolyte temperature and salt density in this application. From light salt brine to salt density of 30g/L from the cold water in the North Atlantic ocean to warm water in the Indian Ocean. The anode we supply must be acid pickled to remove the oxide of the titanium substrate, the anode will be subjected to high speed electrolyte flow and reverse condition of electrode. The generating of sodium hypochlorite by seawater electrolysis is to kill marine organism and prevent algae growing on the ship hull and cooling water system for the power plant. For seawater electrolytic cell, the anode is Platinum Group Metals oxide coated while the cathode is plain titanium. In order to adapt to the different circumstances and conditions of electrolyte, we have developed anodes suitable for different working conditions to improve salt working efficiency and prolong anode life span.

Advantages of titanium anode assembly

1)Improving anode oxidizability by adding base metal Stannum

2)Low chlorine potential (≤1.13V), high sodium hypochloride efficiency

3)Stable chemical properties and high catalytic activity

Application Advantages

Titanium Anode Assembly is a complete electrochemical unit designed for superior performance, efficiency, and durability in harsh operating environments. Built with high-purity titanium substrates and mixed metal oxide (MMO) or platinum group coatings, it ensures stable operation and long-term cost efficiency.

Key Advantages:

- High Corrosion Resistance: Withstands acidic, alkaline, and chloride-rich conditions.

- Long Service Life: Advanced coating technology ensures prolonged operational performance.

- Excellent Conductivity: Provides low voltage loss and high current efficiency.

- Stable Electrochemical Output: Maintains uniform current distribution across the anode surface.

- Customizable Structure: Modular design suitable for varied electrochemical cell systems.

- Eco-friendly and Maintenance-free: Eliminates hazardous emissions and reduces maintenance costs.

Typical Applications:

- Electroplating and metal finishing

- Chlor-alkali production

- Electrolytic copper foil and nickel refining

- Wastewater treatment and electrochlorination systems

- Cathodic protection of pipelines and storage tanks

Be used in a wide range of industries.

Seawater electrolysis

Marine aquaculture

Chlor-alkali industry

Cathodic protection

Electroplating industry

Non-ferrous metal electrolytic extraction

Manufacturing & Process Flow

1. Select suitable Gr1 titanium plate as substrate and cut into customized size.

2. Substrate surface treatment including surface sandblasting, acid Washing- Brushing coating -Sintering -Oxidation-Annealed Repeat this process multiple times according to the coating thickness.

3. Inspection the surface and coating no scratching.

4. Assemble anode and cathode, weld the connection according to customer's drawing.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Our Titanium Anode Assemblies are manufactured under the strictest ISO 9001:2015 quality management standards. Every stage—from raw materials to finished products—is monitored for performance, safety, and compliance.

Inspection Procedures Include:

- Raw Material Verification: Confirm titanium grade, purity, and mechanical strength.

- Coating Quality Test: Check thickness, composition, and adhesion strength.

- Electrical Conductivity Test: Verify low resistance and stable current distribution.

- Dimensional Accuracy: Ensure perfect fit and alignment for assembled structures.

- Final Product Validation: Conduct voltage and electrochemical performance tests under simulated working conditions.

All inspection data are documented and traceable, with full test reports provided for each shipment.

R&D and Customization

Shaanxi Chuanghui Daye invests continuously in research and innovation to improve the durability, efficiency, and versatility of Titanium Anode Assemblies.

R&D Focus Areas:

- Development of next-generation MMO coatings for extended service life.

- Optimized current distribution systems for higher energy efficiency.

- Design of lightweight, modular anode frames to reduce installation complexity.

- Tailored solutions for specific electrochemical and water treatment systems.

Customization Options:

- Coating type: Ru-Ir, IrO₂, Pt, Ta-Ir, or mixed oxide coatings

- Titanium grade: Gr1, Gr2, or customized alloy

- Assembly structure: Plate, mesh, rod, or tubular design

- Electrical connection: Customized terminal or busbar configuration

Our engineers work closely with clients to provide design optimization and technical consultation at every project stage.

Packaging & Global Logistics

We ensure that each Titanium Anode Assembly arrives in perfect condition, no matter the destination.

Packaging Details:

- Anti-rust or vacuum-sealed film wrapping

- Shock-absorbing foam and reinforced wooden cases

- Clearly labeled cartons with product specifications and batch numbers

Logistics Solutions:

- Worldwide air, sea, and land transportation

- Fast dispatch within 7 working days for standard assemblies

- Full tracking and documentation for export shipments

All packaging complies with international export standards and environmental regulations.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

We offer OEM and ODM solutions to meet the specific requirements of global customers.

Service Scope:

- Design and production based on customer drawings

- Private label and branding customization

- Prototype and small-batch manufacturing

- Material and coating selection guidance

- Complete technical and after-sales support

Our OEM services enable clients to integrate reliable Titanium Anode Assemblies into their systems with full performance assurance and cost efficiency.

Inspection Process

Before shipment, every Titanium Anode Assembly undergoes a comprehensive inspection to guarantee product integrity and performance consistency.

- Material Certification Check – Verify titanium grade and compliance with ASTM/GB standards.

- Coating Thickness Test – Ensure uniform coating layers using precision instruments.

- Adhesion and Peel Strength Test – Validate coating bond integrity.

- Electrical Resistance Test – Measure voltage drop and current distribution accuracy.

- Visual and Dimensional Inspection – Confirm surface finish, assembly accuracy, and structure alignment.

- Final Approval and Packaging – Only fully compliant products are released for shipment.

Why Choose Us

- 30+ Years of Industry Expertise: Founded by professionals with deep technical knowledge in rare metal processing.

- Comprehensive Manufacturing Capability: Integrated melting, forging, machining, and coating facilities.

- Certified Quality System: ISO 9001:2015-certified production and inspection management.

- Global Export Experience: Products supplied to over 50 countries worldwide.

- Strong R&D Foundation: Continuous innovation in titanium and rare metal applications.

- Flexible OEM/ODM Support: Customizable sizes, coatings, and assembly designs.

- Efficient Logistics: Fast shipping and reliable global delivery service.

- Excellent After-Sales Service: Dedicated support and quick response to client inquiries.

|

|

|

|

|

|

FAQs

Q1: What coatings are available for Titanium Anode Assemblies?

A1: We offer Ru-Ir, IrO₂, Pt, Ta-Ir, and other mixed metal oxide coatings suitable for various electrochemical processes.

Q2: Can you design the assembly according to my equipment layout?

A2: Yes. We can manufacture fully customized assemblies based on your drawings or specific technical requirements.

Q3: What is the expected lifespan of the Titanium Anode Assembly?

A3: Depending on the coating and working environment, typical service life ranges from 5 to 10 years.

Q4: Do you provide technical consultation for new applications?

A4: Absolutely. Our engineering team offers full technical support, including coating recommendations and system design optimization.

Q5: What certifications do your products comply with?

A5: All products conform to ISO 9001:2015, ASTM, and GB standards, ensuring international reliability and traceability.

Q6: How soon can I receive my order?

A6: Standard models can be shipped within 7 working days, while custom orders depend on design and quantity.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email