- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

superior tantalum wire

2. Diameter: 0.15–5 mm

3. Tensile strength: 220–320 MPa

4. Density: 16.65 g/cm³

5. Corrosion resistant

6. Applications: High-end electronics, medical

7. Elongation: 12–25%

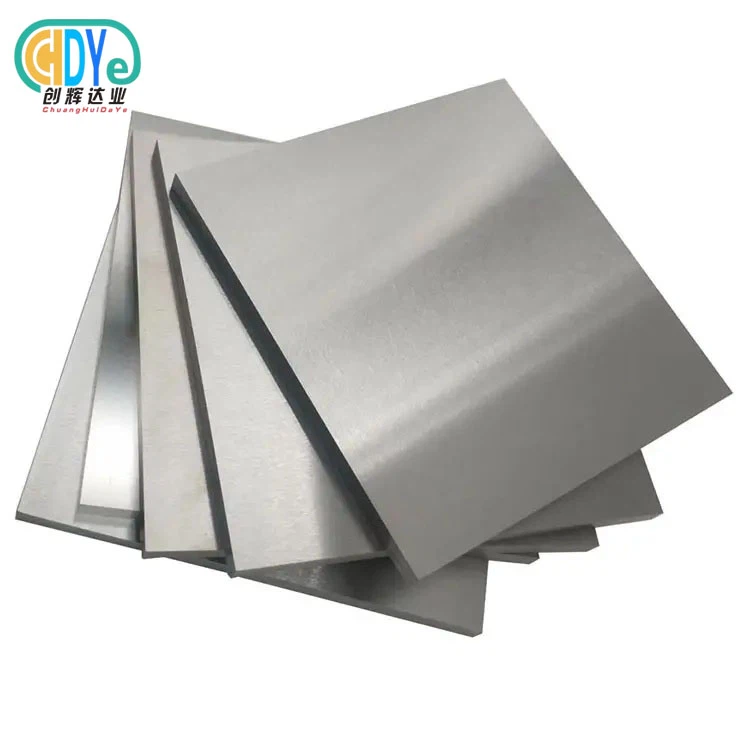

Product introduction

When you need uncompromising quality and reliability, our superior tantalum wire delivers exceptional performance across the most demanding applications. At Shaanxi Chuanghui Daye Metal Material Co., Ltd., we combine over 30 years of rare metal expertise with advanced manufacturing techniques to produce tantalum wire that exceeds industry standards. Our products serve customers in more than 50 countries worldwide, providing the durability, corrosion resistance, and biocompatibility required for high-end electronics, medical devices, and specialized industrial applications. With purity levels exceeding 99.95% and precise dimensional control, you can trust our superior tantalum wire to meet your most critical specifications.

Key Features and Benefits

Our tantalum wire offers unique advantages that make it the preferred choice for demanding applications:

- Exceptional Purity: Ta content exceeds 99.95% for optimal performance

- Outstanding Corrosion Resistance: Immune to harsh chemicals and environmental conditions

- Superior Biocompatibility: Safe for medical implants and body-contact applications

- High Tensile Strength: 220-320 MPa provides excellent mechanical properties

- Excellent Ductility: 12-25% elongation allows for complex forming operations

- Temperature Stability: Maintains properties at extreme temperatures

- Electrical Conductivity: Reliable performance in electronic applications

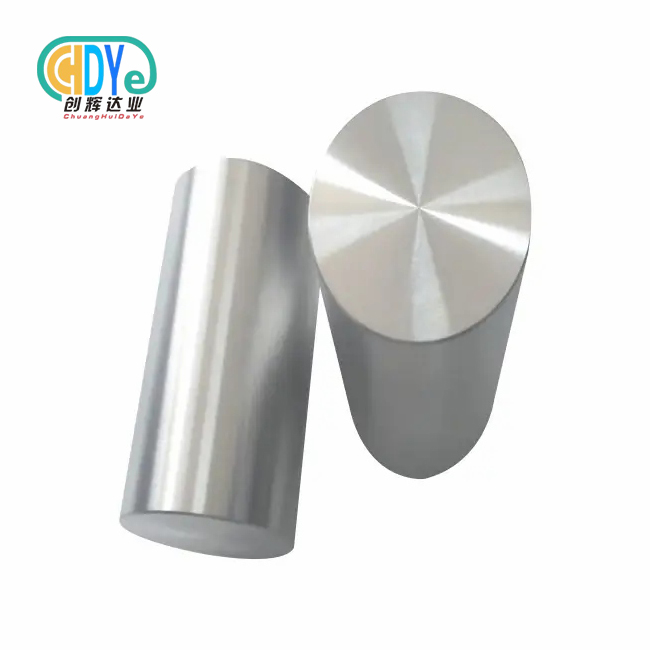

Technical Specifications

|

Material |

Tantalum Niobium Rod / Bar R05240 (Ta-40Nb) Pure tantalum: R05200, R05400; TantalumTungsten Rod / Bar R05252 (Ta-2.5W), R05255 (Ta-10W). |

|

Standard |

ASTM B365 |

|

Service |

Customized OEM, OEM/ODM/Customized, ODM Available |

|

Packing |

Wooden box |

|

Delivery time |

Stock size will be 1-5 days, normal production time is about 15 days |

|

Payment terms |

30%TT in advance,70% balance before shipment |

| Condition |

Annealed |

| Certificate |

ISO 9001:2015 |

Available Grades and Materials

We offer various tantalum grades to meet your specific requirements:

- RO5200: Pure tantalum for general applications

- RO5400: Tantalum-tungsten alloy for enhanced strength

- Custom Alloys: Tailored compositions for specialized needs

All materials comply with international standards including ASTM B365 and ASTM F560.

Chemical composition

|

Grade |

Chemical Composition (≤%) |

|||||||||||

|

Ta |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Nb |

O |

C |

H |

N |

|

|

Ta1 |

Bal. |

0.005 |

0.005 |

0.002 |

0.01 |

0.01 |

0.002 |

0.03 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

Ta2 |

Bal. |

0.03 |

0.02 |

0.005 |

0.04 |

0.03 |

0.005 |

0.1 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

TaNb3 |

Bal. |

0.03 |

0.03 |

0.005 |

0.04 |

0.03 |

0.005 |

<3.5 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

TaNb20 |

Bal. |

0.03 |

0.03 |

0.005 |

0.04 |

0.03 |

0.005 |

17.0-23.0 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

Ta2.5W |

Bal. |

0.005 |

0.005 |

0.002 |

3 |

0.01 |

0.002 |

0.04 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

Ta10W |

Bal. |

0.005 |

0.005 |

0.002 |

11 |

0.01 |

0.002 |

0.04 |

0.015 |

0.01 |

0.0015 |

0.01 |

Manufacturing Process

Our state-of-the-art manufacturing process ensures consistent quality:

- Raw Material Selection: High-purity tantalum ingots sourced from certified suppliers

- Melting and Refining: Vacuum arc melting for optimal purity

- Drawing Operations: Precision cold drawing through diamond dies

- Heat Treatment: Controlled annealing for desired mechanical properties

- Quality Control: Comprehensive testing at each production stage

- Final Inspection: Dimensional and surface quality verification

|

|

|

|

|

|

|

|

Applications and Industries

Superior tantalum wire finds applications across diverse industries:

Medical Sector:

- Surgical implants and prosthetics

- Cardiac stents and pacemaker components

- Orthopedic hardware

Electronics Industry:

- Capacitor manufacturing

- Semiconductor components

- High-frequency applications

Industrial Applications:

- Chemical processing equipment

- Vacuum furnace heating elements

- Corrosion-resistant fasteners

Product Dimensions and Tolerances

We maintain strict dimensional control to ensure your specifications are met:

- Diameter Tolerance: ±0.01mm for diameters <1mm, ±0.02mm for larger sizes

- Straightness: <0.5mm per meter

- Surface Finish: Ra <0.8μm

- Length: Custom lengths up to 1000mm

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Features in Detail

1. Corrosion resistance: Tantalum wire has good corrosion resistance and can be used in extreme environments. It has good corrosion resistance to most acids and bases, such as at 150 ° C, it will not corrode in any concentration of hydrochloric acid, nitric acid, phosphoric acid, and organic acids, but is sensitive to hydrofluoric acid and mixtures of hydrofluoric acid and nitric acid

2. Conductivity: Tantalum wire has good conductivity and is suitable for use in electronic components. For example, it can be used to manufacture electrodes in electronic components such as capacitors, inductors, and resistors

3. Processability: Tantalum wire can be processed at high temperatures and is easily combined with materials such as ceramics and glass, making it suitable for making other components of electronic devices

4.Low Thermal Expansion Coefficient: The wire maintains dimensional stability under temperature changes, ideal for precision applications.

Quality Assurance and Testing

Every batch undergoes rigorous testing to ensure compliance with your specifications:

- Chemical Analysis: ICP-MS verification of purity levels

- Mechanical Testing: Tensile strength and elongation measurements

- Dimensional Inspection: Precision measurement equipment

- Surface Quality: Visual and microscopic examination

- Certificate of Analysis: Detailed documentation provided with each shipment

|

|

|

OEM & Customization Services

We understand that your applications may require specific configurations. Our engineering team works closely with you to develop custom solutions including:

- Special diameter requirements

- Unique length specifications

- Custom alloy compositions

- Specialized surface treatments

- Application-specific packaging

Packaging and Shipping

Your tantalum wire is carefully packaged to ensure safe delivery:

- Primary Packaging: Protective spools or coils

- Secondary Packaging: Moisture-resistant containers

- Shipping: Expedited delivery options available

- Documentation: Complete traceability records included

|

|

|

Why Choose Us

Located in China's "Titanium Capital," Shaanxi Chuanghui Daye Metal Material Co., Ltd. brings decades of rare metal expertise to every project. Our founder's 30+ years in the industry ensures you receive products that meet the highest standards. We focus on competitive pricing, on-time delivery, and customer-focused service that builds lasting partnerships.

|

|

|

|

|

|

FAQs

Q: What makes your tantalum wire superior to competitors?

A: Our superior tantalum wire combines exceptional purity (>99.95%) with precise manufacturing control and comprehensive quality testing.

Q: Can you provide custom dimensions?

A: Yes, we offer custom diameters from 0.15-5mm and lengths as your requirements to meet your specific requirements.

Q: What certifications do your products have?

A: Our products comply with ASTM B365, ASTM F560, and other international standards. Certificates of analysis are provided with each shipment.

Q: What is your typical lead time?

A: Standard products ship within 1-2 weeks. Custom orders may require 2-3 weeks depending on specifications.

Contact Us

Ready to experience the difference that superior tantalum wire can make in your applications? Our technical team is standing by to discuss your specific requirements and provide detailed quotations.

Email: info@chdymetal.com

Contact us today to learn how our superior tantalum wire can enhance your project's performance and reliability.

Learn about our latest products and discounts through SMS or email