- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

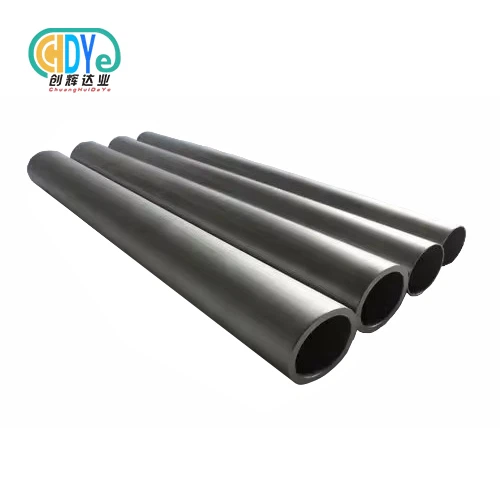

customized tantalum sputtering target

Density:16.6 g/ cm 3

Purity : 99.95%min

size: customized

Condition: Vacuum Annealed

Product Introduction

Tantalum targets share the same properties as their raw materials. Tantalum is a rare, hard, bluish-gray, and highly corrosion-resistant refractory metal. Its melting point is 2980°C and its density is 16.68 g/cm³. Tantalum boasts a range of excellent properties, including a high melting point, low vapor pressure, good cold working properties, high chemical stability, strong resistance to liquid metal corrosion, and a high dielectric constant of its surface oxide film. Tantalum has important applications in high-tech fields such as electronics, metallurgy, steel, chemicals, cemented carbide, atomic energy, superconducting technology, automotive electronics, aerospace, healthcare, and scientific research.

When you need precise thin film deposition for advanced manufacturing, our customized tantalum sputtering target delivers exceptional performance. At Shaanxi Chuanghui Daye Metal Material Co., Ltd., we understand that your projects require specific dimensions, purity levels, and material properties. That's why we specialize in creating tailored solutions that meet your exact requirements. Our tantalum targets combine superior material quality with flexible customization options, ensuring optimal results for your sputtering applications.

Key Features and Benefits

- Ultra-high purity ranging from 99.5% to 99.99% for consistent coating quality

- Flexible sizing from 50mm to 600mm diameter to fit various sputtering chambers

- Precise tolerances of ±0.01mm for critical microelectronics applications

- Dense microstructure with grain size ≤30μm ensuring uniform film deposition

- Strong bonding with backing plates achieving ≥50 MPa adhesion strength

- Excellent thermal stability supporting high-temperature sputtering processes

Technical Specifications

|

Grade |

Ta1 |

Ta2 |

Ta3 |

|

|

Chemical Compositions (%,<=/max) |

Ta |

≥99.95 |

≥99.99 |

≥99.995 |

|

C |

0.01 |

0.003 |

0.002 |

|

|

N |

0.005 |

0.005 |

0.004 |

|

|

H |

0.0015 |

0.0015 |

0.001 |

|

|

O |

0.015 |

0.01 |

0.005 |

|

|

Nb |

0.02 |

0.005 |

0.002 |

|

|

Fe |

0.005 |

0.0005 |

0.0001 |

|

|

Ti |

0.002 |

0.001 |

0.0005 |

|

|

W |

0.005 |

0.001 |

0.001 |

|

|

Mo |

0.005 |

0.001 |

0.001 |

|

|

Si |

0.005 |

0.001 |

0.0001 |

|

|

Ni |

0.002 |

0.0001 |

0.0001 |

|

|

Other Properties |

Average Grain Size (μm) |

≤100um |

||

|

Roughness(Ra, μm) |

Ra0.8-1.2 |

|||

|

Flatness(mm) |

≤0.10% |

|||

Specification

|

Shape |

Thickness(mm) |

Width(mm) |

Length(mm) |

Diameter(mm) |

|

Round |

3-25 |

- |

- |

≤450 |

|

Square |

3-25 |

≤600 |

≤2000 |

- |

Available Grades and Materials

We offer premium tantalum grades to meet diverse application requirements:

- Ta 1: Standard grade with 99.95% minimum purity

- Ta 2: High-purity grade for demanding applications

- High purity can be customized

Each grade undergoes vacuum annealing treatment for optimal material properties.

Manufacturing Process

Our advanced production process ensures consistent quality:

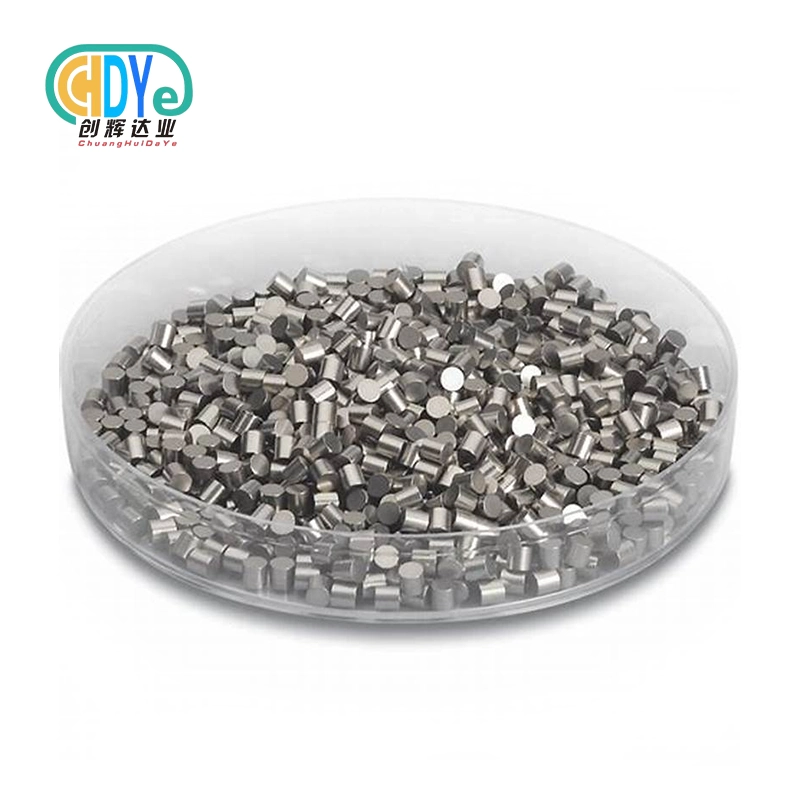

- Powder preparation using sodium thermal reduction method

- Cold isostatic pressing at >200 MPa pressure for uniform density

- Vacuum sintering at >2400°C for complete consolidation

- Precision machining using CNC milling technology

- Surface treatment with alkaline washing or mechanical finishing

- Quality inspection to verify all specifications

|

|

|

|

|

|

|

|

Applications and Industries

Your customized tantalum sputtering target serves critical roles across multiple industries:

Electronic Manufacturing: Semiconductor integrated circuits, capacitors, resistors, and microprocessors benefit from tantalum's excellent electrical properties.

Display Technology: LCD and OLED displays use tantalum films for electrodes and barrier layers, enhancing performance and durability.

Optical Coatings: Camera lenses, eyeglass coatings, and architectural glass applications leverage tantalum's optical properties.

Medical Devices: Biocompatible tantalum coatings improve implant performance and longevity.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We manufacture targets to your exact specifications:

- Standard diameters: 76mm, 100mm, 152mm, 200mm, 254mm, 300mm

- Custom sizes: Any diameter from 50-600mm available

- Thickness options: 2-40mm range with precise control

- Surface finishes: Machined or alkaline-washed surfaces

- Backing plates: Various materials including copper, molybdenum, and stainless steel

Quality Assurance and Testing

Every target undergoes comprehensive testing:

- Chemical composition analysis

- Density measurement verification

- Grain structure examination

- Surface quality inspection

- Dimensional accuracy confirmation

- Bonding strength validation

|

|

|

OEM & Customization Services

We excel at creating solutions tailored to your needs. Whether you require specific alloy compositions, unique geometries, or special surface treatments, our experienced team works closely with you. Our customized tantalum sputtering target options include rotary targets, planar targets, and complex shapes designed for specialized equipment.

Packaging and Shipping

Your targets receive careful protection during transit:

- Protective packaging prevents contamination and damage

- Vacuum sealing maintains surface cleanliness

- Custom crating for oversized or fragile items

- Global shipping to over 50 countries worldwide

- Documentation includes certificates of analysis and material traceability

Why Choose Us

With over 30 years of rare metal industry experience, we bring unmatched expertise to every project. Located in China's "Titanium Capital," we have access to premium raw materials and advanced processing facilities. Our commitment to quality, competitive pricing, and reliable delivery has earned trust from customers across the United States, Germany, South Korea, Singapore, and beyond.

We focus on building long-term partnerships through honest communication, continuous improvement, and customer-first service.

|

|

|

|

|

|

FAQs

Q: What lead times can I expect for custom targets?

A: Standard customizations typically require 1-2weeks, while complex specifications may need 2-3 weeks.

Q: Can you provide material certificates?

A: Yes, we include complete certificates of analysis with chemical composition and physical property data.

Q: Do you offer sample quantities?

A: We can provide small samples for evaluation before full production orders.

Contact Us

Ready to discuss your customized tantalum sputtering target requirements? Our technical team is here to help you find the perfect solution.

Email: info@chdymetal.com

Contact us today for competitive pricing, technical support, and reliable delivery of premium tantalum sputtering targets tailored to your exact specifications.

Learn about our latest products and discounts through SMS or email