- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

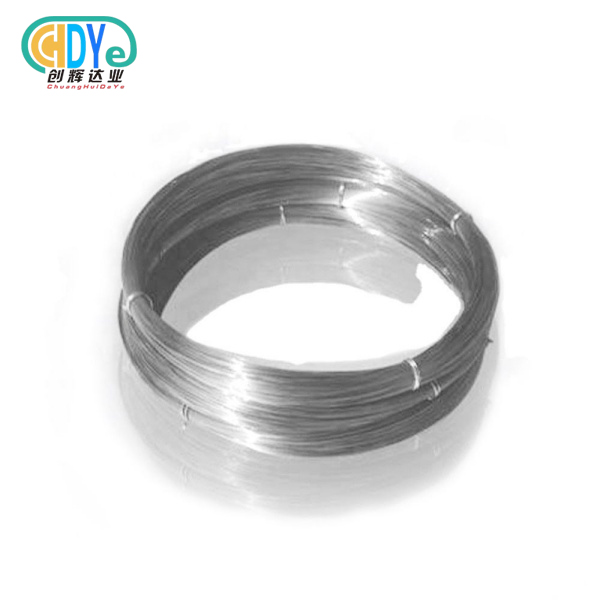

Titanium Coil Tube

Product Introduction

Titanium coil tube is a precision-engineered coiled tubing product made from high-quality titanium and titanium alloys. Designed for continuous fluid circulation systems, it offers outstanding corrosion resistance, superior heat transfer efficiency, and excellent mechanical stability under cyclic temperature and pressure conditions.

Shaanxi Chuanghui Daye Metal Material Co., Ltd. manufactures titanium coil tubes through precision coiling and annealing processes to achieve uniform curvature, excellent roundness, and high fatigue resistance. Each coil is customized according to customer design requirements for use in heat exchangers, condensers, evaporators, and chemical process systems.

Chdymetal is a global supplier of titanium coil tube, support customized It is widely used in heat exchange equipment, such as tube heat exchanger, coil heat exchanger, serpent tube heat exchanger, condenser, evaporator and pipeline, etc.

Products parameter

|

Item |

Titanium coil tube |

|

Structure |

Tube Heat Exchanger |

|

Dimension(L*W*H) |

Customized / produce as your drawing |

|

Material |

Pure Titanium gr1 gr2 |

|

Heat exchanger type |

Shell and tube condenser |

|

Application |

Industry |

|

Usage |

tube heat exchanger, coil heat exchanger, serpent tube heat exchanger, condenser, evaporator and pipeline, etc. |

|

Package |

Foam inside Wooden Case outside |

|

MOQ |

1kg and sample is provided |

|

Delivery |

Stock size is 1-5 days Normal production time 15 working days |

|

shape |

Circle, circle, square, serpentine |

|

Payment terms |

30%TT in advance,70% balance before shipment |

Chemical composition

|

Grades |

N |

C |

H |

Fe |

O |

Al |

V |

Pd |

Mo |

|

Gr 1 |

0.03 |

0.08 |

0.015 |

0.2 |

0.18 |

/ |

/ |

/ |

/ |

|

Gr 2 |

0.03 |

0.08 |

0.015 |

0.3 |

0.25 |

/ |

/ |

/ |

/ |

|

Gr 3 |

0.05 |

0.08 |

0.015 |

0.3 |

0.35 |

/ |

/ |

/ |

/ |

|

Gr 7 |

0.03 |

0.08 |

0.015 |

0.3 |

0.25 |

/ |

/ |

0.12~0.25 |

/ |

|

Gr 9 |

0.03 |

0.08 |

0.015 |

0.25 |

0.15 |

2.5~3.5 |

2.0~3.0 |

/ |

/ |

|

Gr 11 |

0.03 |

0.08 |

0.015 |

0.2 |

0.18 |

/ |

/ |

0.12-0.25 |

/ |

|

Gr12 |

0.03 |

0.08 |

0.015 |

0.3 |

0.25 |

/ |

/ |

/ |

0.2~0.4 |

|

Gr 16 |

0.03 |

0.08 |

0.015 |

0.3 |

0.25 |

/ |

/ |

0.04-0.08 |

/ |

|

Gr 17 |

0.03 |

0.08 |

0.015 |

0.2 |

0.18 |

/ |

/ |

0.04-0.08 |

/ |

Characteristics of titanium coil tube

Excellent corrosion resistance in many media, so the tube wall can be relatively thin, improving the heat transfer effect.

Smooth surface, no dirt layer, greatly reducing the dirt coefficient.

Low density, high strength, small volume and weight of titanium coils.

Superior Heat Transfer Performance: High thermal conductivity and smooth internal surface enhance fluid flow efficiency.

Excellent Corrosion Resistance: Performs reliably in seawater, chemical solutions, and chlorinated environments.

Flexible Design: Available in various coil diameters, lengths, and winding forms to meet specific system layouts.

Lightweight & Durable: High strength-to-weight ratio reduces system load and extends service life.

High Fatigue Strength: Withstands repeated bending and vibration under cyclic temperature conditions.

Clean & Non-Toxic: Ideal for industries requiring purity such as pharmaceuticals, food processing, and desalination.

Applications

Titanium coil tube is an ideal solution for industries that demand compact design and efficient heat transfer performance:

- Heat Exchangers: Cooling and heating coils in condensers, evaporators, and recuperators.

- Marine & Offshore Systems: Seawater cooling and desalination plant tubing.

- Chemical Equipment: Corrosive fluid pipelines, reactors, and process loops.

- Power Generation: Condenser coils in nuclear, geothermal, and thermal plants.

- Medical & Pharmaceutical Systems: Coiled tubing for sterilization and temperature control systems.

- Aerospace & Defense: Lightweight coiled heat exchangers and hydraulic fluid circuits.

Each coil tube is engineered to deliver long-term stability and high operational safety under continuous use.

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

At Shaanxi Chuanghui Daye, titanium coil tube production integrates precise forming and controlled heat treatment processes:

- High-Purity Melting & Rolling: Titanium billets are melted and rolled into fine-grain seamless tubes.

- Precision Drawing & Coiling: Tubes are cold-drawn and coiled under tension control for uniform curvature.

- Bright Annealing: Performed in a high-purity argon atmosphere to ensure a clean and smooth internal surface.

- Leak Testing & Pressure Calibration: 100% tested for gas tightness and pressure reliability.

- Dimensional Finishing: Ends are cut, deburred, and leveled according to customer installation standards.

Our advanced production line ensures every coil maintains stable shape, consistent wall thickness, and superior mechanical performance.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality management is integrated throughout the production process to ensure reliable and consistent performance.

Shaanxi Chuanghui Daye is ISO 9001:2015 certified, and all titanium coil tubes undergo comprehensive inspections before delivery.

Main Quality Procedures Include:

- Raw material chemical composition verification

- Mechanical testing (tensile, yield, elongation)

- Dimensional accuracy inspection

- Eddy current and hydrostatic pressure testing

- Helium leak detection for high-purity applications

- Final visual and packaging examination

Our strict control system guarantees that every coil meets international standards and performs flawlessly in end-user applications.

OEM & Customization Services

We provide flexible customization for titanium coil tube products based on specific customer requirements:

- Coil diameter, wall thickness, and coil length customization

- U-shaped, spiral, or pancake coiling forms

- End fittings, connections, and threading options

- Integration with heat exchangers, manifolds, or tube sheets

- Special alloy configurations (Ti–Pd, Ti–Nb, Ti–Mo) for extreme environments

- Prototype development and OEM branding support

Our engineering team ensures each coil tube is optimized for maximum performance and cost efficiency.

Packaging & Global Logistics

All titanium coil tubes are packaged to ensure safe handling and corrosion-free delivery:

- Inner Packaging: Vacuum-sealed or moisture-proof wrapping with soft film protection.

- Outer Packaging: Plywood crates or reinforced spools for long-length coils.

- Labeling: Clear identification including material grade, specifications, and lot number.

- Shipping Options: Air, sea, or express courier delivery with global tracking service.

Each shipment is handled with care to preserve product integrity during transportation.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

Inspection Process

1. Appearance and dimension inspection to ensure every titanium tube meets tolerances,no cracks, pits or other defects on the surface.

2. 100% Straightness inspection.

3. 100% Hydro Testing.

4. Ultrasonic and eddy current testing make sure the product without cracks and scratch.

5. Testing Tensile strength, yield strength by our Tension Tester and the Third party lab to double check the quality.

Why Choose Us

- Over 30 years of manufacturing experience in titanium and rare metal tubing

- Advanced coiling and annealing equipment ensuring precision quality

- Comprehensive quality assurance system certified to ISO 9001:2015

- OEM/ODM customization for special designs and applications

- Fast delivery—standard coil sizes available within 7–10 days

- Proven export record to 50+ countries

- Dedicated technical and after-sales support for international clients

Our consistent product quality, engineering expertise, and customer-focused service make us a reliable partner in the titanium tubing industry.

|

|

|

|

|

|

FAQs

Q1: What is the maximum continuous length for a titanium coil tube?

A1: We can produce continuous coils up to 150 meters, depending on diameter and wall thickness.

Q2: Are your coils suitable for seawater cooling systems?

A2: Yes, our titanium coil tubes are highly resistant to seawater corrosion, making them ideal for marine and desalination applications.

Q3: Can you supply coils with welded ends or fittings?

A3: Absolutely. We can provide welded end caps, flanged ends, or threaded connections according to customer drawings.

Q4: What type of inspection reports are included?

A4: Each shipment includes EN 10204 3.1 certificates, pressure test results, and dimensional inspection reports.

Q5: Do you provide installation guidance or custom coil design?

A5: Yes, our technical team offers design consultation and engineering support for system integration and installation.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email