- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

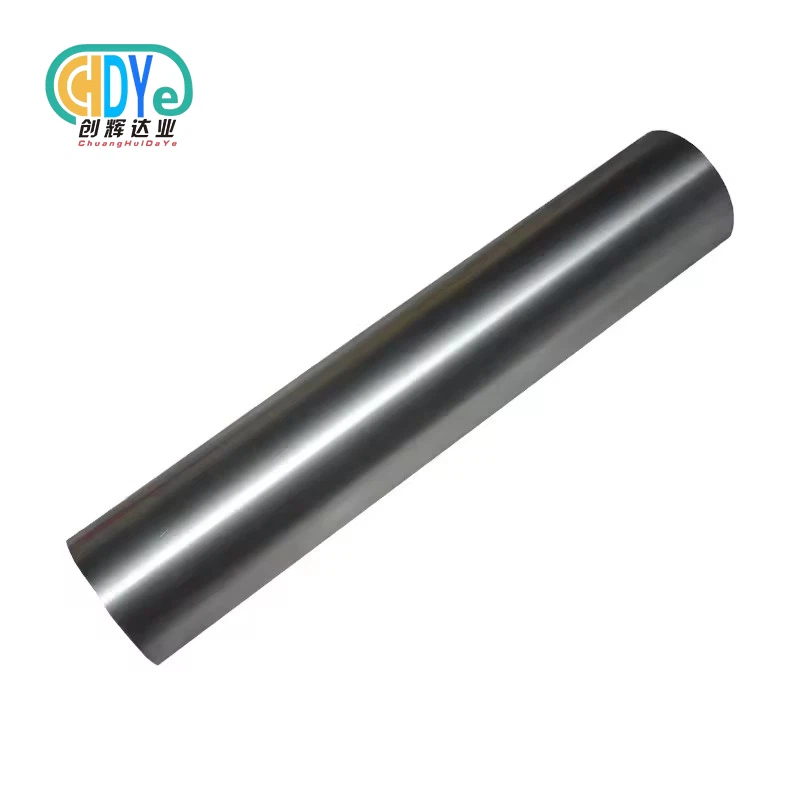

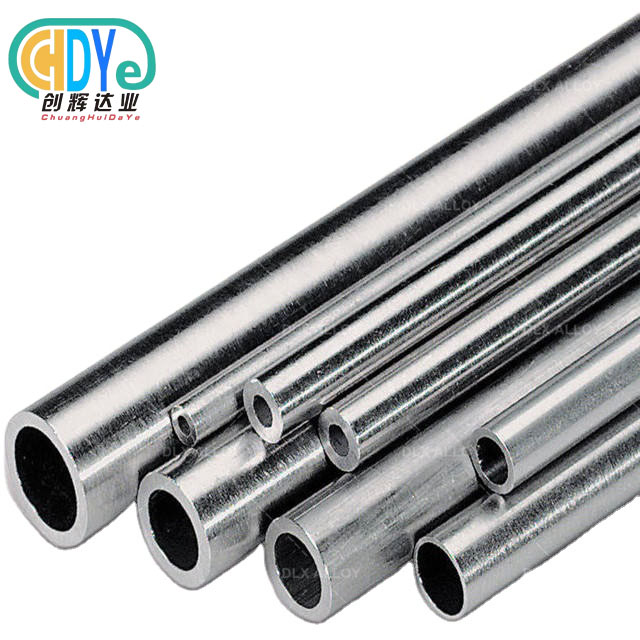

Pure Tantalum Tube

2.Standard: ASTM B521

3.State: Annealed state (M) or hard state (Y) 4.Type: seamless tube and welded tube

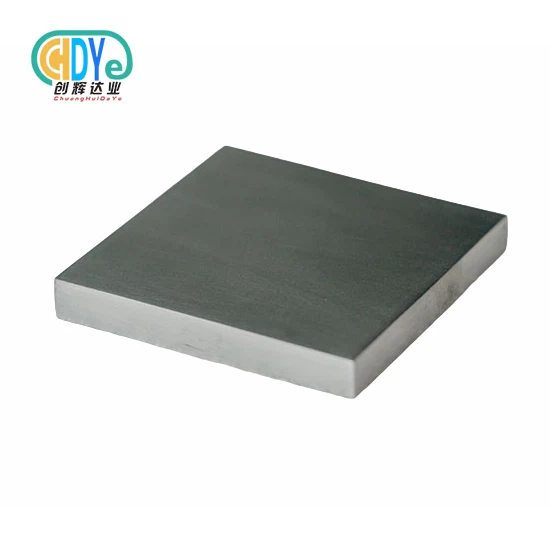

Product Introduction

Product name: Pure Tantalum tube (seamless tube)

Grade: Ta1, Ta2, TaW2.5, TaW7.5, TaW10, TaNb3, TaNb20, TaNb40

Standard: ASTM B521

Purity: The purity of pure tantalum is greater than 99.95%;

State: Annealed state (M) or hard state (Y)

Type: seamless tube

Size:

|

Outer Diameter (mm) |

Wall thickness (mm) |

Length(mm) |

|

0.8~3.0 |

0.05~1.0 |

100≤L≤5000 |

|

3.0~80 |

0.2≤W≤5 |

100≤L≤5000 |

|

Tantalum and Tantalum Alloys Tube Dimension and Tolerance (mm) |

|||||

|

Outer Diameter |

Outer Diameter Tolerance |

Wall Thickness |

Outer Diameter |

Outer Diameter Tolerance |

Wall Thickness Tolerance |

|

Tolerance |

|||||

|

|

± 0.04 |

± 10% of Wall Thickness |

|

± 0.06 |

± 10% of Wall Thickness |

|

> 5 - 15 |

± 0.08 |

> 15 - 25 |

± 0.10 |

||

|

> 25 - 35 |

± 0.13 |

> 35 - 40 |

± 0.13 |

||

|

> 40 - 50 |

± 0.15 |

||||

Pure Tantalum tube manufacturing features

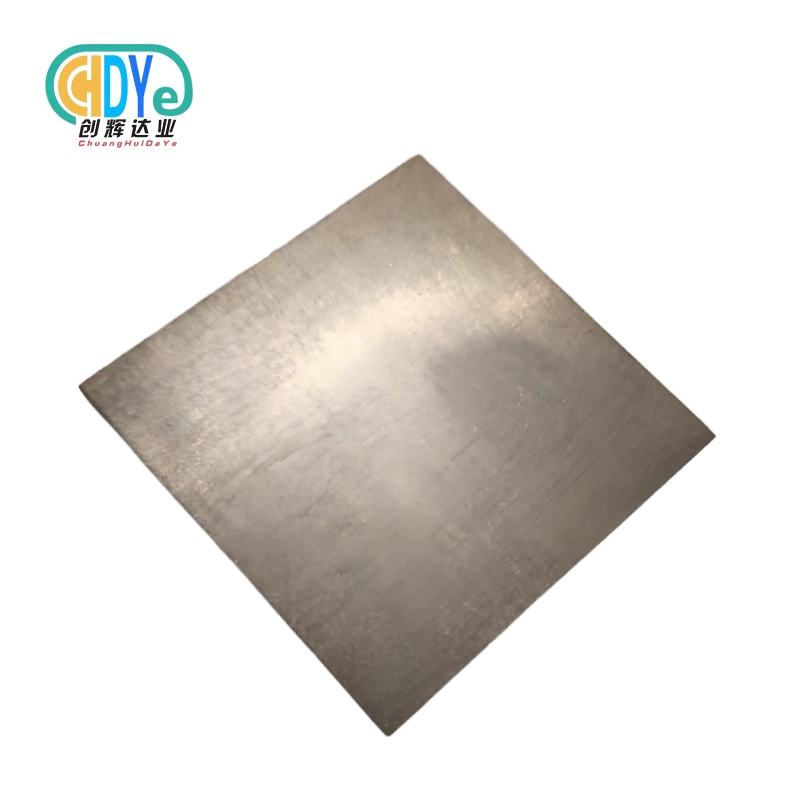

Tantalum can be made into welded tubes and seamless tubes, and has a wide range of uses. Seamless tubes are made by extrusion, tube reduction or deep drawing of plates. The welding manufacturing method is to first form the plate strip, then make it into a tube shape, and then weld the seam with gas tungsten arc (GTAW).

Application Advantages

• Chemical reaction vessels and heat exchangers, pipes, condensers, bayonet heaters, helical coils, U-tubes.

• Thermocouple and its protection tube.

• Liquid metal containers and pipes, etc.

• Tantalum tube for cutting the tantalum ring for jewelry field.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Shaanxi Chuanghui Daye adopts advanced production techniques to ensure the purity, density, and dimensional accuracy of every tantalum tube.

Process Flow:

- Raw Material Selection: 99.95% or higher pure tantalum ingots

- EB Furnace Melting: Refined using electron beam furnace to ensure ultra-high purity

- Forging and Rolling: Controlled deformation to enhance grain uniformity

- Extrusion and Drawing: Multi-stage cold drawing with intermediate annealing

- Annealing Treatment: Precise heat treatment to achieve optimal mechanical properties

- Machining and Finishing: Precision sizing, polishing, and cutting as per specifications

- Inspection and Testing: Full dimensional, mechanical, and purity checks

- Final Packaging: Vacuum-sealed and anti-rust protection for global shipment

|

|

|

|

|

|

|

|

Quality Control & Inspection

Chuanghui Daye operates under the ISO 9001:2015 Quality Management System, ensuring each tantalum tube meets international standards such as ASTM B521 / B708.

Inspection Parameters:

- Chemical Composition: Verified by spectrographic and XRF analysis

- Mechanical Properties: Tensile strength, yield strength, elongation

- Dimensional Accuracy: Precision tolerances checked with micrometers and gauges

- Surface Quality: Visual and microscopic inspection for defects

- Ultrasonic Testing: Detects internal flaws and voids

- Cleanliness & Purity: Ensures no contamination during fabrication

R&D and Customization

With a strong R&D foundation, Shaanxi Chuanghui Daye specializes in developing tailored solutions for complex industrial applications.

R&D Capabilities Include:

- Development of ultra-fine tantalum capillary tubes for semiconductor and medical use

- Customization of wall thickness, diameter, and tolerance to client specifications

- Research into tantalum-niobium alloy systems for enhanced corrosion resistance

- Collaboration with research institutions for material innovation and application optimization

Packaging & Global Logistics

To ensure product integrity, each tantalum tube is packaged and transported with the utmost care.

Packaging Standards:

- Vacuum-sealed or nitrogen-filled inner wrapping

- Anti-rust film and protective foam layers

- Outer protection: strong export-grade wooden crates

- Clear product labeling with heat number, batch ID, and dimensions

Logistics:

- Global delivery via air, sea, or express shipping

- Reliable partnerships with international logistics providers

- Tracking support and flexible delivery schedules

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Chuanghui Daye offers comprehensive OEM and ODM services to meet specific industrial requirements:

- Custom dimensions, purity grades, and tolerance levels

- Tube bending, flanging, and welding per client drawings

- Prototype and low-volume production for R&D projects

- Technical consultation for material selection and application design

Inspection Process

Each production stage undergoes systematic inspection to guarantee consistency and compliance.

Inspection Workflow:

- Raw Material Verification – Supplier certification & internal chemical analysis

- In-Process Quality Check – Diameter, wall thickness, straightness, and grain structure

- Non-Destructive Testing (NDT) – Ultrasonic and eddy current inspection

- Final Product Verification – Full mechanical and dimensional reports

- Documentation & Certification – Mill test report (MTR) and export documentation

Why Choose Us

- 30+ Years of Expertise: Founded by a rare metal expert with decades of industry experience

- ISO-Certified Factory: Strict adherence to ISO 9001:2015 standards

- Advanced Equipment: Electron beam furnaces, precision lathes, and rolling machines

- Global Recognition: Exported to over 50 countries across Europe, America, and Asia

- Rapid Delivery: 7-day dispatch for standard sizes

- Tailored Solutions: Custom R&D and OEM capabilities for specialized applications

- Quality Guarantee: 100% product inspection and traceable certification

|

|

|

|

|

|

FAQs

Q1: What is the purity level of your pure tantalum tube?

A1: We supply tantalum tubes with purities ranging from 99.9% to 99.95% minimum, conforming to ASTM B708 standards.

Q2: What are the available dimensions?

A2: Outer diameter: 3mm–120mm; Wall thickness: 0.3mm–10mm; Length: up to 3000mm. Custom dimensions are available.

Q3: Can you provide small-batch or prototype production?

A3: Yes. We support small-batch manufacturing and custom prototyping for R&D and pilot projects.

Q4: What testing reports can you provide?

A4: We offer chemical composition analysis, mechanical property reports, and third-party inspection upon request.

Q5: How do you ensure packaging safety during transport?

A5: All tubes are vacuum-packed with multiple protective layers and export-standard wooden cases to prevent oxidation or mechanical damage.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email