- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

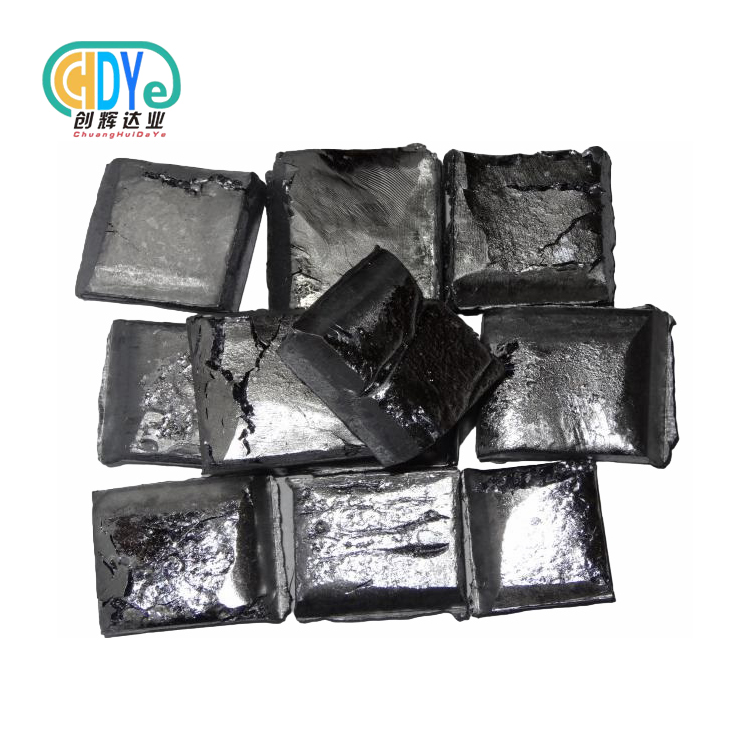

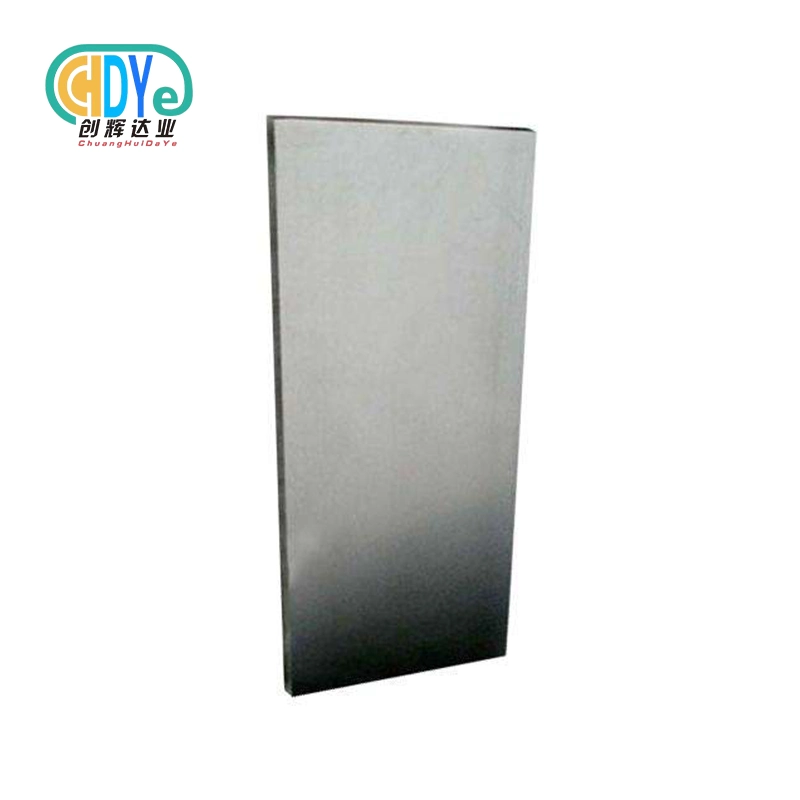

high purity tantalum target

2.Density:16.6 g/ cm 3

3.Purity : 99.95%min

4.size: customized

5.Condition: Vacuum Annealed

6.Surface: Alkaline wash surface / machined

7.Processing technic: CNC Milling Machinery

Product Introduction

Looking for reliable high purity tantalum target materials for your critical applications? Our premium tantalum sputtering targets deliver exceptional quality with 99.995% purity, meeting the demanding requirements of advanced microchip manufacturing and precision coating processes. With over 30 years of expertise in rare metal materials, we understand your need for consistent, ultra-clean performance in every production run.

Our high purity tantalum target products feature total impurities ≤50 ppm and gas impurities H+N+O ≤120 ppm, ensuring vacuum-grade quality for your most sensitive applications. Whether you're working in semiconductor manufacturing, display technology, or optical coating, our targets provide the reliability and performance you demand.

Key Features and Benefits

- Ultra-High Purity: 99.995% minimum purity ensures contamination-free deposition

- Superior Electronic Performance: RRR ≥60 provides excellent conductivity characteristics

- Uniform Microstructure: Grain size ≤20 μm delivers consistent thin film quality

- High Sputtering Efficiency: ≥96% efficiency maximizes your production output

- Exceptional Stability: Lattice defect ≤0.05% ensures long-term reliability

- Precise Resistivity: 13.5 μΩ·cm for predictable electrical properties

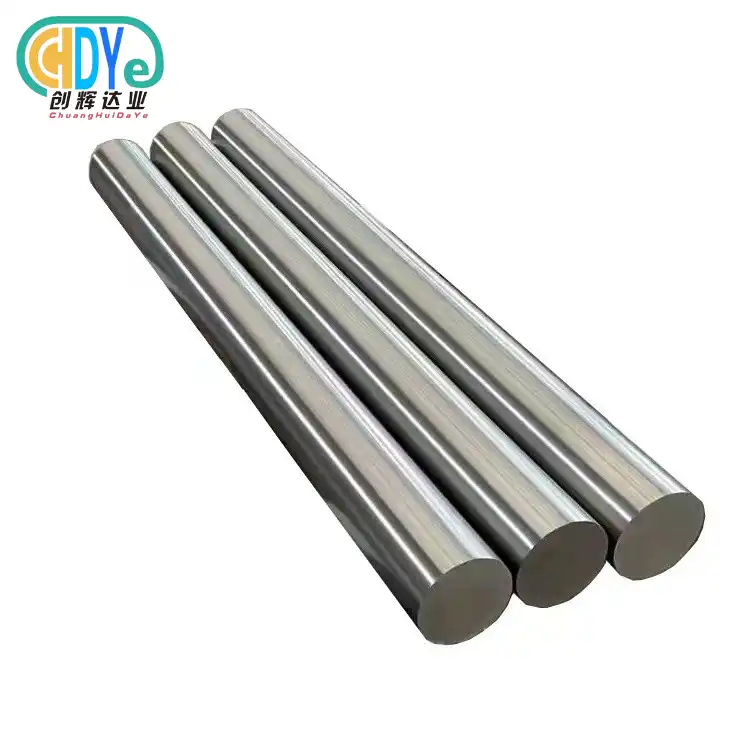

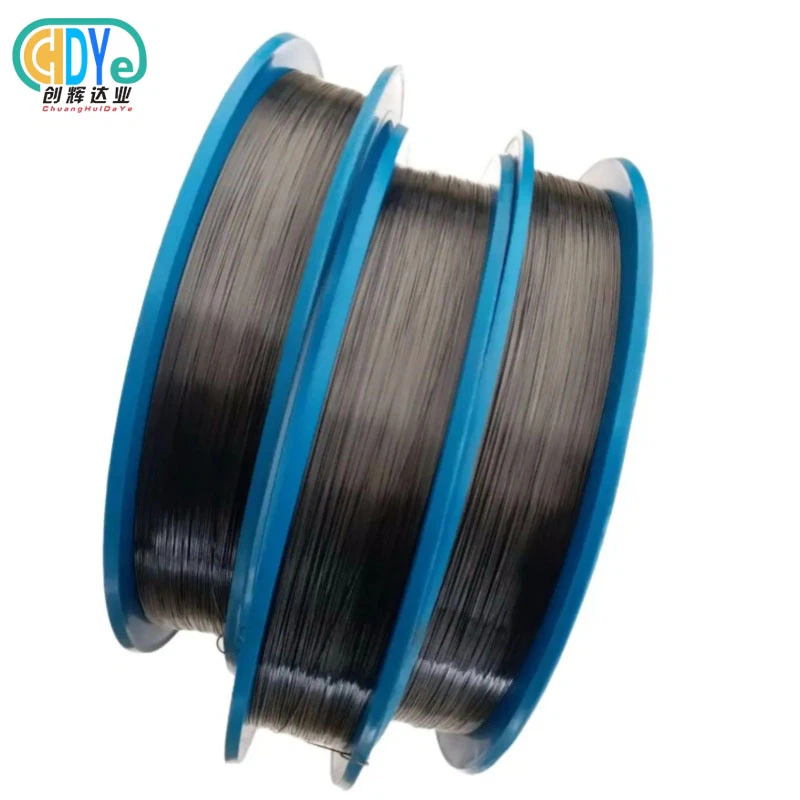

Technical Specifications

|

Product name |

high purity tantalum target |

|

Application |

Electronic Light Source Part;Implantation Parts.etc |

|

Purity |

99.95% Min |

|

Density |

16.65g/cm3 |

|

Surface |

Polished and Black |

|

Size |

Φ2.0—100mm*L,customized |

|

Chemical Composition |

Pure Tantalum Rods/Bars |

|

Melting point |

3400℃ |

|

Packing |

Wooden box |

|

Production process |

Tantalum raw material - electron beam vacuum melting - forging - polishing - inspection - delivery |

chemical composition

|

Grade |

Chemical Composition (≤%) |

||||||||||||

|

Ta |

Fe |

Si |

Ni |

W |

Mo |

Ti |

Nb |

O |

C |

H |

N |

||

|

Ta1 |

Bal. |

0.005 |

0.005 |

0.002 |

0.01 |

0.01 |

0.002 |

0.03 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

|

Ta2 |

Bal. |

0.03 |

0.02 |

0.005 |

0.04 |

0.03 |

0.005 |

0.1 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

|

TaNb3 |

Bal. |

0.03 |

0.03 |

0.005 |

0.04 |

0.03 |

0.005 |

<3.5 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

|

TaNb20 |

Bal. |

0.03 |

0.03 |

0.005 |

0.04 |

0.03 |

0.005 |

17.0-23.0 |

0.02 |

0.01 |

0.0015 |

0.01 |

|

|

Ta2.5W |

Bal. |

0.005 |

0.005 |

0.002 |

3.0 |

0.01 |

0.002 |

0.04 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

|

Ta10W |

Bal. |

0.005 |

0.005 |

0.002 |

11 |

0.01 |

0.002 |

0.04 |

0.015 |

0.01 |

0.0015 |

0.01 |

|

Available Grades and Materials

We offer premium tantalum targets in multiple grades to match your specific requirements:

- Ta-1 Grade: Ultra-high purity for semiconductor applications

- Ta-2 Grade: High performance for general sputtering applications

- Custom Compositions: Tailored alloys for specialized requirements

All grades undergo vacuum annealing treatment for optimal internal structure and performance consistency.

Manufacturing Process

Our advanced production process ensures superior quality at every step. We begin with high-purity tantalum powder produced through sodium thermal reduction. Cold isostatic pressing at pressures exceeding 200 MPa creates dense, uniform ingots.

Vacuum sintering at temperatures above 2400°C develops the target microstructure. Precision rolling and controlled heat treatment optimize the material properties. CNC milling machinery delivers exact dimensions and superior surface finishes.

This powder metallurgy approach creates fine, uniform internal structures without texture, perfect for high-end sputtering applications.

|

|

|

|

|

|

|

|

Applications and Industries

Electronic Chip Manufacturing: Essential for semiconductor integrated circuit production, forming tantalum thin films for capacitors and resistors with precise thickness control.

Display Technology: Critical component in LCD and OLED manufacturing for electrode and barrier layer formation, enhancing display performance and longevity.

Optical Coating: Improves transmittance and reduces reflection in camera lenses, eyeglass lenses, and architectural glass applications.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Product Dimensions and Tolerances

We provide fully customized dimensions to match your equipment specifications. Standard surface finishes include alkaline wash and precision machined options. Our high purity tantalum target products maintain tight tolerances for consistent performance.

Quality Assurance and Testing

Every target undergoes comprehensive testing including purity analysis, microstructure evaluation, and dimensional verification. Our quality systems ensure each high purity tantalum target meets your exact specifications before shipment.

|

|

|

OEM & Customization Services

We specialize in custom solutions tailored to your unique requirements. From specific dimensions to specialized surface treatments, our experienced team works closely with you to develop the perfect solution.

Packaging and Shipping

Products are carefully packaged in protective materials to prevent contamination and damage. We coordinate international shipping to over 50 countries, ensuring safe delivery of your critical materials.

|

|

|

|

|

|

|

|

|

|

|

|

Why Choose Us

Located in China's "Titanium Capital," we combine three decades of rare metal expertise with state-of-the-art manufacturing capabilities. Our founder's extensive industry experience ensures you receive knowledgeable support and reliable products.

We're committed to competitive pricing, on-time delivery, and customer-focused service. Trust our proven track record serving customers across the United States, Germany, South Korea, Singapore, and beyond.

|

|

|

|

|

|

FAQs

Q: What makes your tantalum targets suitable for semiconductor applications?

A: Our 99.95% purity and ≤50 ppm total impurities ensure contamination-free deposition critical for chip manufacturing.

Q: Can you provide custom dimensions?

A: Yes, we specialize in fully customized solutions to match your specific equipment and process requirements.

Q: What quality certifications do you provide?

A: We provide comprehensive test reports including purity analysis, microstructure evaluation, and dimensional measurements.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email