- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

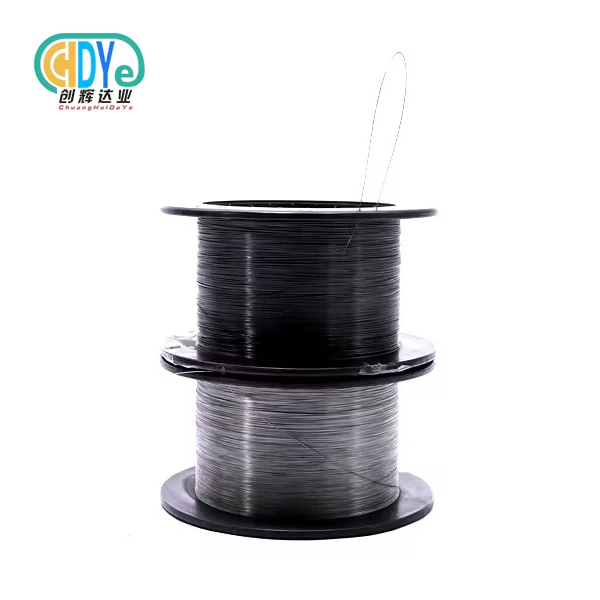

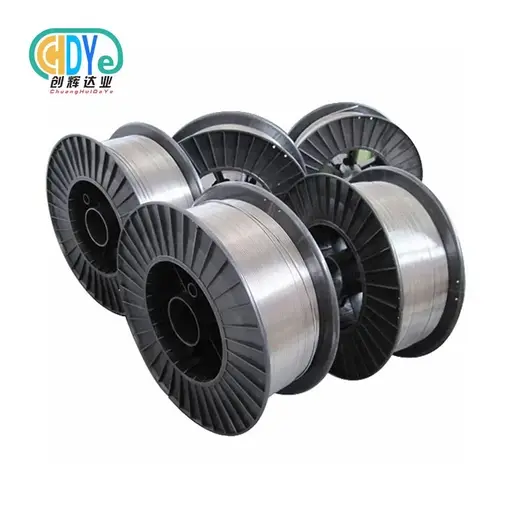

Pure Titanium Wire

2.Various grade and size

3.Straight type and coil type are all ok

4.Free samples are available

Product Overview

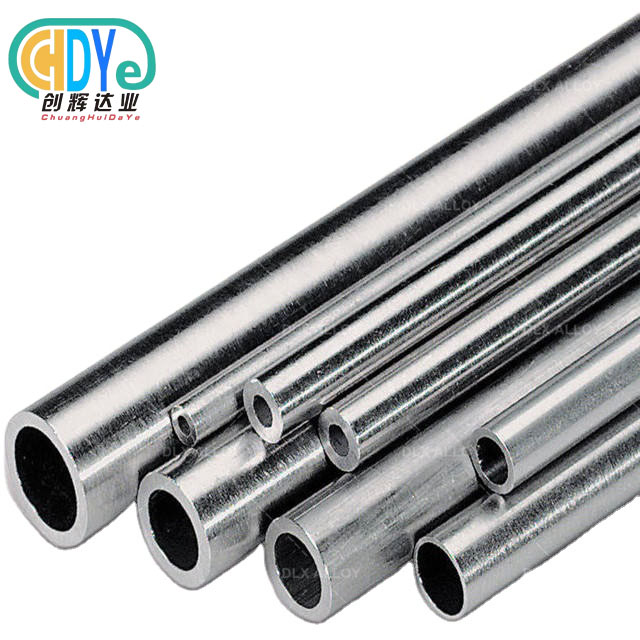

Pure Titanium Wire is a high-performance material manufactured by Shaanxi Chuanghui Daye Metal Material Co., Ltd., located in Baoji, the “Titanium Valley of China.” This product is made from 99.6% or higher purity titanium and offers excellent strength-to-weight ratio, corrosion resistance, and biocompatibility. It is widely used in chemical processing, marine, aerospace, electronics, and medical industries.

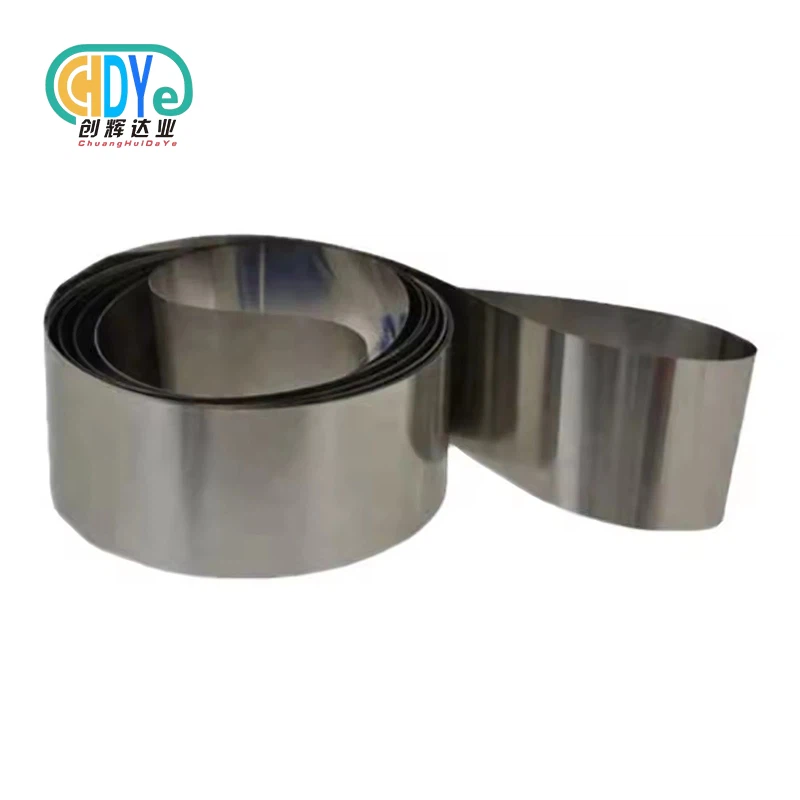

Our Pure Titanium Wire is available in coil, straight cut, and spool forms, providing excellent formability and surface finish for welding, weaving, fastening, and machining applications. Each batch is processed under strict quality control, ensuring consistency, purity, and mechanical stability.

Chdymetal is a global metal supplier of pure titanium wire, we can provide various grade and type, As its unique combination of high strength, light weight, corrosion resistance, bio-compatibility, and higher temperature performance, pure titanium wire is widely used in aerospace, medical, industrial, and oil and gas industries.

1. Normal size at stock so we can arrange quick delivery within 1-3days

2. Various grade and size

3. Straight type and coil types are all ok

4. Free samples are available

|

Standard |

ASTM B863, ASTM B348, ASTM F67, ASTM F136, etc. |

|

Grade |

Gr1, Gr2, Gr3, Gr5, Gr7, Gr23, etc. |

|

Technique |

Hot Rolled, Cold Rolling, Annealed |

|

Straight |

Dia.:1.0mm-5.0mm ( tolerance: +/-0.05mm ) |

|

Coiled |

Dia.:0.03mm-5.0mm ( tolerance: +/-0.05mm ) |

|

Length |

Coils or Customers' Requests |

|

Surface |

Black, Pickled, Polished ( For Dia. >1mm ) |

|

Packing terms |

Internal foam soft packing External export wooden box |

|

Payments terms |

30%TT in advance,70%balance before shipment |

Physical & Mechanical Performance

1. Excellent Strength-to-Weight Ratio

Pure titanium offers strong mechanical strength with only 60% of steel’s weight.

2. Superior Corrosion Resistance

Performs exceptionally well in seawater, nitric acid, and chloride environments.

3. Biocompatibility & Non-Toxicity

Safe for medical, dental, and food-grade applications.

4. Low Thermal Expansion & High Melting Point

Ensures dimensional stability under high-temperature conditions.

5. Stable Electrical Conductivity

Used for electrochemical and power applications requiring pure metallic contact.

Product Highlights & Advantages

High Purity: Each batch exceeds 99.6% Ti content, verified by spectrochemical analysis.

Excellent Workability: Easily drawn, bent, or coiled for various industrial applications.

Corrosion-Resistant: Performs well in acids, alkalis, and saline environments.

Lightweight & Durable: Reduces equipment weight while extending service life.

Non-Magnetic & Non-Allergenic: Ideal for sensitive medical and electronic uses.

Multiple Surface Options: Bright-annealed or pickled for aesthetic and technical needs.

Full Traceability: All products come with batch numbers and MTC reports.

Our Products

Our Service

*Rich experience in metal industry and we can give you professional advice when you select the suitable material.

*We offer FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

*Stock products with various grade and size, we can arrange quick delivery on the same day.

Key mechanical properties include:

- Excellent tensile-to-weight ratio

- High fatigue resistance under cyclic stress

- Non-magnetic and biocompatible characteristics

- Stable mechanical behavior across wide temperature ranges (-250°C to +400°C)

- Outstanding corrosion resistance against acids, alkalis, and seawater environments

These qualities make our wire suitable for both structural and functional applications where reliability is critical.

Product Highlights & Advantages

- Purity-Controlled Smelting – Using electron beam and vacuum arc furnaces, each melt achieves ultra-low inclusion and impurity levels.

- Dimensional Precision – Automated laser measurement ensures diameter accuracy within ±0.01 mm, meeting the strictest OEM standards.

- Superior Surface Finish – Mirror-polished and oxide-free surfaces ensure excellent welding performance and electrical conductivity.

- Mechanical Stability – Enhanced tensile strength and elasticity tailored for high-load and cyclic applications.

- Custom Alloy Solutions – Flexible combinations of Ti–Al–V, Ti–Pd, Ti–Mo, and Ti–Fe systems for corrosion or heat resistance optimization.

- Global Certification Support – Full documentation including mechanical, chemical, and ultrasonic test reports for international compliance.

- Fast and Reliable Supply Chain – Ready-to-ship inventory and 7–15 day lead time for standard grades.

The production process of titanium wire

1. Raw material preparation: Titanium wire production usually uses titanium and titanium alloy billets as raw materials. These raw materials need to undergo strict screening and inspection to ensure their quality and purity.

2. Drawing process: The core of titanium wire production lies in the drawing process. By using precision drawing equipment, the wire blank is passed through the die holes of the drawing die under the action of drawing force, thereby producing titanium and titanium alloy wires of different specifications. During the drawing process, the size and surface smoothness of the metal wire can be precisely controlled. Cold drawing is the most commonly used drawing method in the production of metal wires and wires

3. Chemical analysis: During the production process, it is necessary to conduct chemical analysis on raw materials and finished products to ensure that their composition meets standards.

4. Acid washing: The surface of the drawn titanium wire may have oxides or impurities, which require acid washing treatment to remove the surface oxide layer and impurities, and improve the surface smoothness and purity of the titanium wire

5. Heat treatment: Titanium wire that has undergone acid washing treatment needs to undergo heat treatment to eliminate stress and improve the strength and toughness of the titanium wire. The temperature and time of heat treatment need to be precisely controlled to ensure that the performance of titanium wire meets the requirements.

6. Surface treatment: Surface treatment of titanium wire includes polishing, electroplating and other processes to enhance the surface glossiness and corrosion resistance of titanium wire, and improve its service life in practical applications

7. Testing: Finally, it is necessary to conduct quality testing on the produced titanium wire, including inspection of appearance quality, dimensional accuracy, chemical composition, and other indicators, to ensure that the titanium wire meets customer requirements and standards.

|

|

|

|

|

|

|

|

Quality Control & Inspection

- Chemical Composition: Verified by ICP-OES and Spectrometer

- Tensile & Yield Testing: Performed under ASTM B348 and B863 standards

- Ultrasonic Testing: Ensures internal soundness and structural uniformity

- Surface Inspection: Detects scratches, cracks, or inclusions

- Dimensional Accuracy: ±0.01 mm tolerance across full length

- Certifications: ISO 9001:2015, SGS, EN 10204 3.1

- Every production batch is traceable from titanium sponge to final spool, supported by a complete Material Test Certificate (MTC).

Application Advantages

1. Currently, more than 80% of titanium and titanium alloy wires are used as welding wires, such as welding of various titanium equipment, welding pipes, repair welding of aircraft jet engine turbine discs and blades, welding of casings, etc.

2. Due to its excellent corrosion resistance, titanium wire has been widely used in chemical, pharmaceutical, paper making and other industries. It can be woven into a mesh as a seawater filter, pure water filter, chemical filter, etc.

3. Titanium and titanium alloy wires are also used to manufacture fasteners, load-bearing components, springs, etc. due to their good comprehensive performance.

4. In the medical and health industry, due to its excellent bio-compatibility, titanium and titanium alloy wires are used to manufacture medical devices, implanted crowns, skull fixation, etc.

5. Some titanium alloy wires with shape memory function, such as titanium-nickel alloy wires, eyeglass frames, etc.

6. In the electroplating and water treatment industries, titanium and titanium alloy wires are used to manufacture various electrodes.

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

R&D and Customization

- Customized diameter, tolerance, and surface finish per client request

- Available in coil, spool, or straight-cut wire forms

- OEM packaging and branding service for distributors

- Custom mechanical property adjustment through annealing

- Small-batch trial production for new applications

- Our technical team works closely with global partners to develop new titanium wire solutions for emerging markets.

Packaging & Global Logistics

- Inner Layer: Vacuum-sealed plastic film or anti-rust wrapping

- Middle Layer: Soft foam padding to prevent mechanical damage

- Outer Package: Export-standard carton or wooden box

- Labeling: Includes grade, diameter, batch number, and weight

- Delivery Options: Air, sea, or express courier (FedEx/DHL/TNT)

- All packages meet international shipping and environmental compliance standards.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

Global Partnership & Case References

- Europe: Long-term supply for titanium mesh welding and electrode manufacturing

- North America: Precision titanium wire for aerospace and medical instruments

- Asia-Pacific: Large-scale supply for chemical and marine corrosion-resistant systems

- Middle East: Titanium wire for desalination and oil-refining industries

Our export network covers more than 60 countries, offering stable supply, competitive pricing, and professional technical support.

Why Choose Us

- Over 30 years of experience in titanium wire manufacturing

- Advanced melting and drawing equipment ensuring precision control

- Full compliance with ASTM, AMS, and ISO standards

- Custom OEM & ODM service for international buyers

- Prompt global delivery with strong logistics capability

- Experienced technical team offering welding and forming advice

- Excellent after-sales service and product warranty

|

|

|

|

|

|

FAQ

Q1: What grades of pure titanium wire are available?

We offer Gr1 and Gr2 titanium wire with purity levels above 99.6%.

Q2: Can you provide small diameter wire below 0.2 mm?

Yes, micro-diameter titanium wire can be customized for medical or electronic applications.

Q3: What surface finishes can you provide?

Bright-annealed, polished, and pickled finishes are all available.

Q4: What is your typical lead time?

Standard sizes: 7–10 days; customized orders: 20–25 days depending on complexity.

Q5: Do you provide third-party inspection reports?

Yes, SGS, TUV, or BV inspection can be arranged upon request.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email