- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

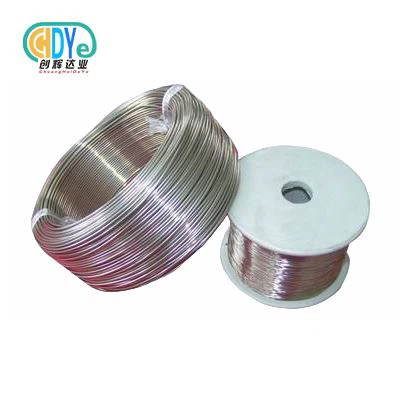

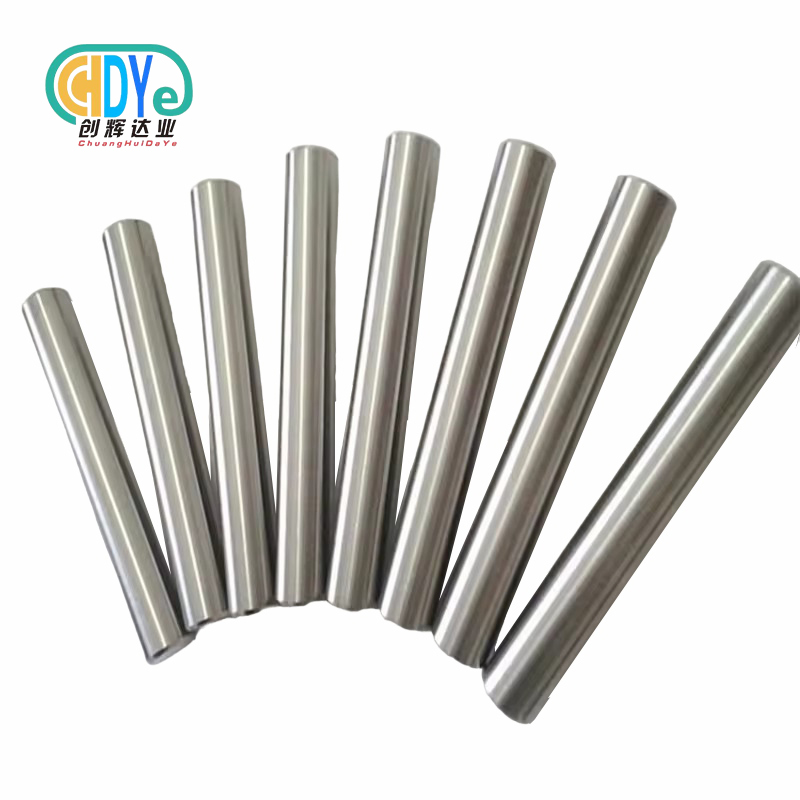

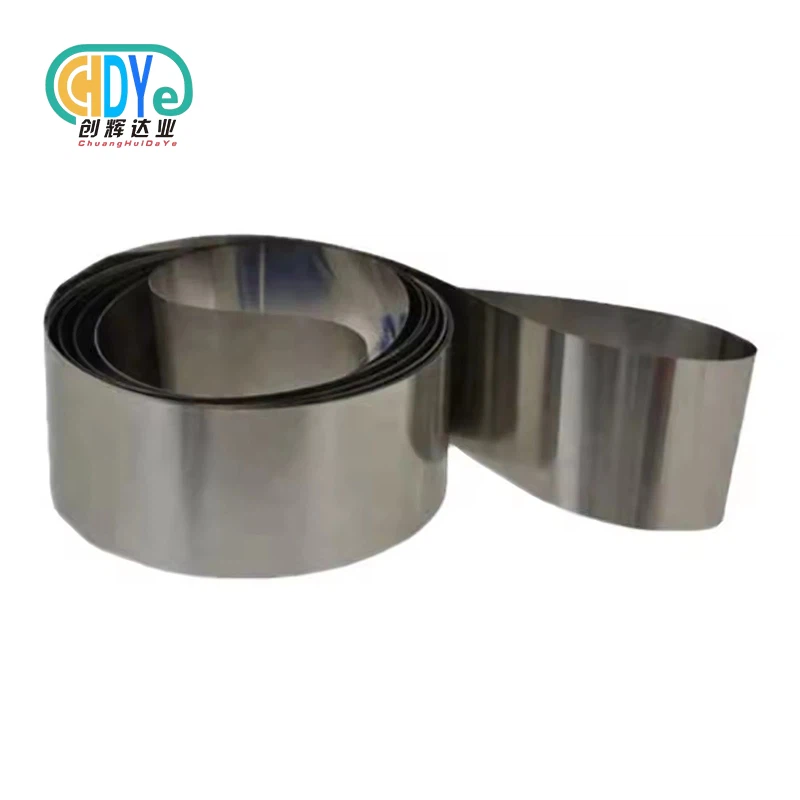

Niobium and Niobium Alloys Tube

2.Grade:R04200, R04210, R04251, R04261

3.Support sample order

Product Introduction

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a professional manufacturer and supplier of Niobium and Niobium Alloys Tube, offering products with high purity, excellent ductility, and superior resistance to heat and corrosion. These tubes are widely used in industries that demand exceptional performance under extreme conditions, such as electronics, aerospace, chemical processing, and nuclear applications.

Our Niobium and Niobium Alloys Tube products are available in seamless and welded forms, strictly manufactured according to ASTM, AMS, and GB standards. With advanced melting, rolling, and machining facilities, we ensure consistent wall thickness, smooth internal surfaces, and precise dimensional accuracy to meet global customer specifications.

Specification

Niobium and niobium alloy tubes are used in steel, ceramic, electronic, nuclear energy and superconductor. Chdymetal is a global supplier of Niobium and niobium alloy tube and we can provide customized niobium products.

1.Grade: R04200, R04210, R04251, R04261

2. Standard: ASTM B394

3. Size: OD3-100*wall thickness 0.5-5mm*Length200-6000mm

4. Packing: Foam material inside, wooden box outside.

5. Payments terms :30%TT in advance, 70% balcance before shipping.

6. Surface: sliver grey

7.Purity: 99.9% 99.95% 99.99%

8.MOQ: 1 pc and we support sample order

Application Advantages

Niobium and Niobium Alloys Tube is a preferred material across several key sectors due to its excellent combination of mechanical strength and corrosion resistance:

- Electronics and Semiconductor Industry: Used in sputtering targets, vacuum chambers, and high-purity systems.

- Aerospace Engineering: Suitable for structural and thermal protection components under high-temperature environments.

- Chemical Processing: Resistant to strong acids and alkalis, making it ideal for reactors and heat exchangers.

- Medical Equipment: Used in surgical implants and instruments due to its biocompatibility.

- Energy and Environmental Engineering: Applied in nuclear reactors, superconducting materials, and high-efficiency energy systems.

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

- Raw Material Selection: High-purity niobium or niobium alloy ingots are sourced from verified suppliers.

- Melting & Refining: Electron beam melting ensures a clean and homogeneous structure.

- Forging & Rolling: Precision forging and rolling improve strength and grain uniformity.

- Tube Piercing & Extrusion: Seamless tubes are formed under controlled temperature and pressure conditions.

- Annealing: Heat treatment removes internal stress and enhances ductility.

- Machining & Finishing: Dimensional accuracy and smooth surface finish are ensured.

- Final Testing: Every Niobium and Niobium Alloys Tube is inspected for mechanical and structural integrity before dispatch.

|

|

|

|

|

|

|

|

Quality Control & Inspection

We follow a strict ISO 9001:2015 certified quality management system to ensure product reliability:

- Chemical Analysis: Each batch undergoes spectrometric testing for purity verification.

- Mechanical Testing: Tensile strength, yield strength, and elongation tests confirm performance standards.

- Non-Destructive Testing (NDT): Ultrasonic and eddy current testing detect internal or surface defects.

- Dimensional Verification: Precision instruments guarantee accurate tube dimensions.

- Surface Inspection: Ensure smoothness, uniform finish, and defect-free surfaces.

R&D and Customization

Our R&D team is dedicated to developing and improving Niobium and Niobium Alloys Tube for advanced industrial needs. With over 30 years of metallurgical experience, we focus on:

- Optimizing alloy formulations for enhanced strength and heat resistance.

- Producing ultra-thin or large-diameter tubes for special engineering applications.

- Supporting custom designs, including specific grades, dimensions, and tolerances.

- Providing technical guidance to match client-specific performance requirements.

Packaging & Global Logistics

To guarantee the safe delivery of every Niobium and Niobium Alloys Tube, we adopt international-standard packaging methods:

- Protection: Vacuum-sealed or anti-rust wrapping with foam cushioning.

- Outer Packaging: Strong, export-grade wooden boxes for secure transport.

- Labeling: Clear marks with specifications, grade, and batch numbers.

- Logistics: Fast and reliable air, sea, and land transportation to over 50 countries, including the U.S., Germany, Japan, and South Korea.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

We provide OEM and ODM services to meet various client requirements:

- Manufacturing according to customer drawings or technical specifications.

- Custom dimensions, wall thicknesses, and alloy compositions.

- Prototype development and small-batch trial production.

- Technical consulting and after-sales support.

- Shaanxi Chuanghui Daye is committed to delivering reliable and tailored niobium tube solutions at competitive prices.

Inspection Process

- Raw Material Verification: All niobium ingots are tested for purity and chemical composition.

- In-Process Control: Continuous monitoring during extrusion and annealing.

- Mechanical Testing: Strength and elongation tests ensure product integrity.

- Non-Destructive Testing: Ultrasonic and eddy current inspection for internal flaws.

- Final Review: Dimensional, surface, and visual checks before packaging and shipment.

Why Choose Us

- 30+ Years of Rare Metal Expertise – Deep technical knowledge in niobium metallurgy.

- Comprehensive Facilities – Equipped with advanced melting, forging, and machining systems.

- Strict Quality Control – ISO 9001:2015 certified production management.

- Global Market Recognition – Products exported to more than 50 countries.

- Fast Delivery & OEM Support – Standard orders can be fulfilled within 7 working days.

|

|

|

|

|

|

FAQs

Q1: What grades of niobium alloys do you supply?

A1: We supply pure niobium and niobium alloys such as Nb-Zr and Nb-Ti according to ASTM and customer specifications.

Q2: What is the typical size range for your niobium tubes?

A2: Diameters from 3 mm to 120 mm with wall thicknesses between 0.5 mm and 10 mm are available.

Q3: Do you offer custom surface finishes?

A3: Yes, finishes such as bright, polished, or sandblasted can be provided based on client needs.

Q4: Can you provide third-party inspection certificates?

A4: Absolutely, third-party inspection from SGS, TUV, or other agencies can be arranged upon request.

Q5: What is your standard delivery time?

A5: Normally 7–15 days for stock sizes and about 20–25 days for customized orders.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email