- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

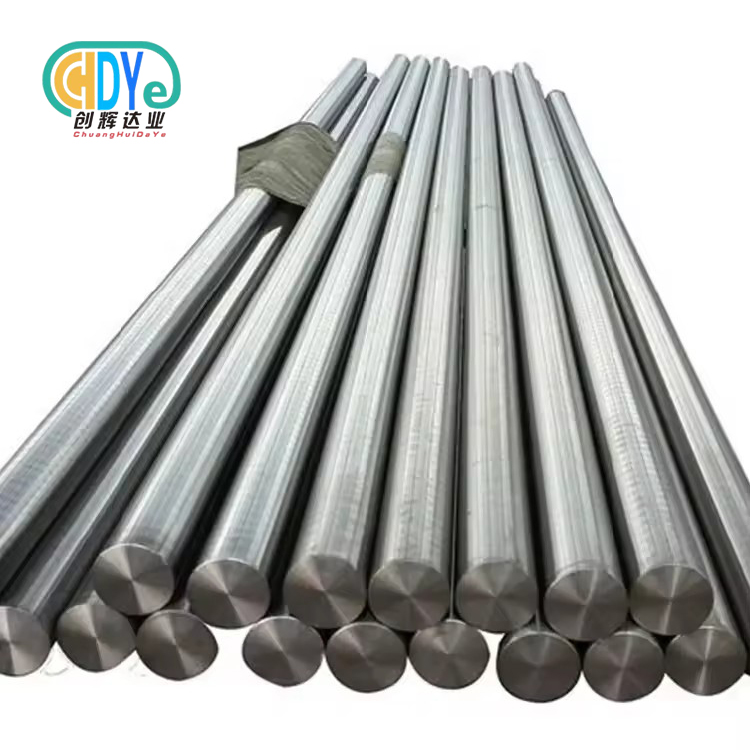

Tantalum Niobium Alloy Wire

2.Material:R05240 (Ta-40Nb)

3.Standard: ASTM B 365

4.Purity: ≥99.9% or 99.95%

Product Introduction

Tantalum-niobium alloy is a tantalum-based alloy with the addition of niobium. Common types of tantalum-niobium alloys include UNS R05240 Ta40Nb, Ta3Nb, Ta20Nb, and Ta30Nb alloys.

60%Tantalum 40%Niobium (Ta40Nb)is one of the most commonly used grades ,can be made into different shapes such as pipe, rod and wire. Ta-40Nb alloy has the advantages of high melting point, corrosion resistance and good cold processing. It is widely used in chemical, atomic, aerospace and other industrial fields.

Tantalum niobium alloy wire Specification:

1. Size: Diameter 0.3-3mm

2. Material:R05240 (Ta-40Nb)

3. Standard: ASTM B 365

4. Purity: ≥99.9% or 99.95%

Tantalum niobium alloy wire Application

1. Aerospace: Used for manufacturing high-temperature structural components and engine parts.

2. Chemical industry: Used as materials for corrosion-resistance equipment.

3. Electronic field: Used for producing capacitors and other electronic components.

4. Medical industry: Used for manufacturing artificial joints, dental implants, and other medical devices.

Other Tantalum Niobium (TaNb) Alloy Products

Tantalum Niobium alloy crucibles

Tantalum Niobium alloy nuts

Tantalum Niobium alloy bolts

Tantalum Niobium alloy heating elements

Tantalum Niobium alloy shielding screens

Application Advantages

- Outstanding Corrosion Resistance: Performs exceptionally in acid and alkali environments such as HCl, H₂SO₄, and HNO₃.

- High Temperature Strength: Maintains mechanical integrity under continuous high-temperature exposure.

- Excellent Formability: Offers superior ductility for drawing, coiling, and welding applications.

- Electrical and Thermal Stability: Provides stable conductivity for electronic and vacuum systems.

- Extended Service Life: Low reactivity and resistance to oxidation ensure long operational durability.

Typical Application Fields:

- Semiconductor and electronic component manufacturing

- High-vacuum and superconductor systems

- Medical and laboratory equipment

- Chemical reactor and heater element fabrication

- Aerospace components and high-temperature furnaces

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Each Tantalum Niobium Alloy Wire is manufactured under a tightly controlled process to ensure purity, uniformity, and precision.

Process Flow:

- Raw Material Selection and Alloy Blending – Strict testing and proportioning of tantalum and niobium raw materials.

- Electron Beam or Vacuum Arc Melting – Ensures purity and homogeneity of the alloy.

- Hot Forging and Rolling – Refines grain structure and improves mechanical properties.

- Cold Drawing and Annealing – Achieves fine tolerance and optimal ductility.

- Straightening and Surface Polishing – Produces clean, oxide-free, and bright surfaces.

- Dimensional and Mechanical Testing – Verifies compliance with ASTM and ISO standards.

- Final Inspection and Secure Packaging.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Quality is a core principle at Shaanxi Chuanghui Daye. The production of Tantalum Niobium Alloy Wire follows ISO 9001:2015 certified procedures, guaranteeing strict inspection at every stage.

Inspection Items Include:

- Chemical Composition Analysis: Conducted via ICP-OES or GDMS for purity verification.

- Tensile and Hardness Testing: Confirms mechanical reliability under stress.

- Surface Examination: Detects scratches, cracks, or inclusions.

- Non-Destructive Testing: Ultrasonic and eddy-current methods used to identify internal defects.

- Dimensional Accuracy Check: Ensures tolerance compliance within ±0.01 mm.

Every inspection step guarantees consistent quality and traceability for each production lot.

R&D and Customization

Our experienced R&D team continually explores alloy optimization, microstructural control, and surface treatment technologies. We provide customized compositions and mechanical properties to suit specific industrial requirements.

Available Customization Options:

- Alloy ratio adjustment (Ta-rich or Nb-rich compositions)

- Diameter range: 0.1 mm – 5.0 mm

- Special mechanical or electrical performance targets

- Customized surface treatment and coiling options

Through close collaboration with clients, we deliver tailored materials for research, prototype, and mass-production applications.

Packaging & Global Logistics

All Tantalum Niobium Alloy Wire products are packaged and shipped according to international export standards.

Packaging Details:

- Vacuum-sealed or anti-rust wrapping

- Foam-lined boxes or wooden crates for export

- Clear product labeling with grade, batch number, and specification

Logistics:

Reliable global shipping via air, sea, or land. With extensive export experience, our logistics system ensures timely delivery and complete documentation support for customers in more than 50 countries.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

Shaanxi Chuanghui Daye provides comprehensive OEM and ODM services for global clients.

Service Capabilities:

- Custom alloy formulation and dimensions

- Prototype or small-batch production

- Material selection and technical consultation

- Private labeling and export certification support

We emphasize flexibility, responsiveness, and high-quality standards to meet the diverse needs of our international partners.

Inspection Process

- Raw material verification and composition analysis

- In-process dimensional and surface monitoring

- Intermediate annealing inspection for uniformity

- Final mechanical, surface, and non-destructive tests

- Packaging integrity check prior to shipment

Each step is meticulously recorded for full traceability and quality documentation.

Why Choose Us

- Over 30 years of expertise in refractory and rare metal manufacturing

- ISO 9001:2015 certified production system

- In-house melting, rolling, and precision machining capabilities

- Proven export performance in 50+ global markets

- 7-day fast delivery for standard specifications

- Dedicated technical and after-sales support for long-term cooperation

|

|

|

|

|

|

FAQs

Q1: What purity level do you offer for this alloy wire?

A1: Standard purity is 99.95%, with ultra-high purity (99.99%) available on request.

Q2: What sizes are available?

A2: Diameters range from 0.1 mm to 5.0 mm, with custom dimensions supported.

Q3: Can you supply small sample quantities?

A3: Yes, sample and prototype quantities are available for R&D or testing.

Q4: What is your standard lead time?

A4: Typical delivery within 7–10 days for standard items; custom orders vary by specification.

Q5: Which industries commonly use this product?

A5: Widely used in aerospace, semiconductor, medical, and chemical processing industries worldwide.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email