- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

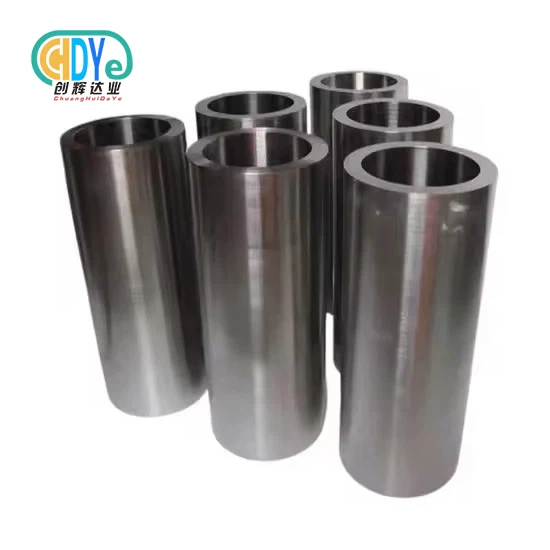

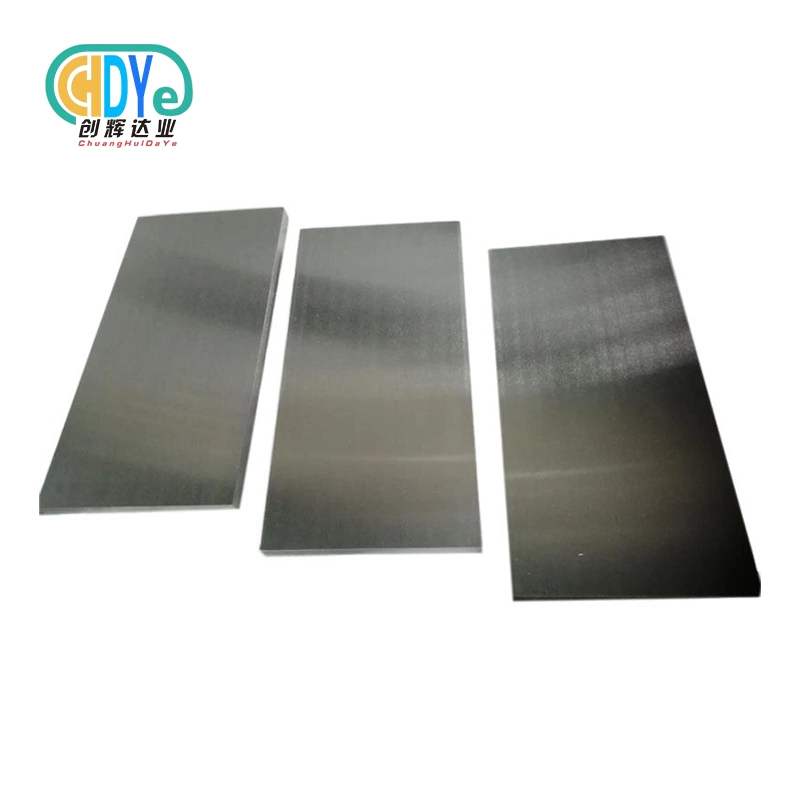

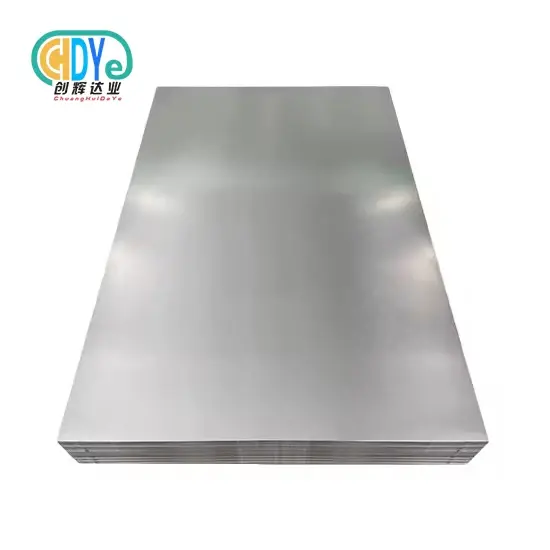

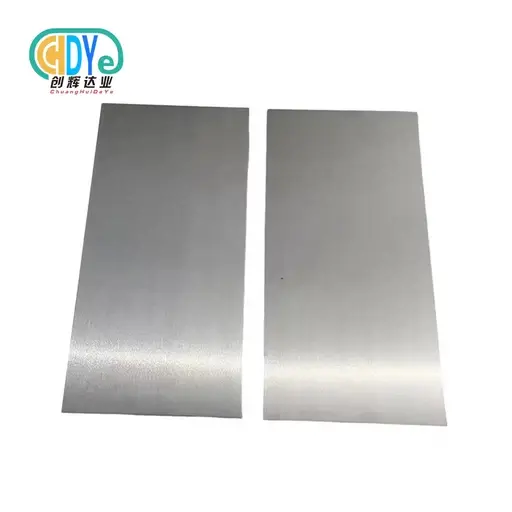

Tantalum Metal Plate

Standard: ASTM B 708

Purity: 99.95%

Product Introduction

Tantalum metal plates have a variety of properties, including high strength, corrosion resistance, high temperature resistance and oxidation resistance, which make them widely used in many fields.

Specification: thickness 0.5-30mm*width10-2500*Length30-3000mm

Standard: ASTM B 708

Purity: 99.95%

Tantalum metal plate processing

Hot rolled

Cold rolled

Cutting

Forming Drilling/ Machining

Grinding

Polishing

Testing

Tantalum metal plate Testing

Dimensional inspection

Surface inspection

Chemical composition testing

Mechanical Properties Test

Application Advantages

Chemical Equipment

Capacitors

Hard-Metal Tooling & Alloys

Electronic Systems

Wind Turbines

Producing Electricity

Home Appliances

Be used in a wide range of industries.

Electronic devices

Medical implants

Steel industry

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

Manufacturing & Process Flow

Shaanxi Chuanghui Daye Metal Material Co., Ltd. utilizes a complete production chain to ensure the superior quality of each Tantalum Metal Plate. The process includes raw material selection → electron beam melting → forging → rolling → heat treatment → surface finishing → dimensional inspection. Each step is carefully monitored by our skilled engineers to guarantee uniform grain structure, precise thickness, and a flawless surface finish. The entire production strictly follows ASTM B708 and ISO 9001:2015 standards.

<

|

|

|

|

|

|

|

|

Quality Control & Inspection

Every Tantalum Metal Plate undergoes rigorous inspection throughout the production process. Our quality control system includes:

- Raw material verification to ensure purity levels above 99.95%

- Dimensional and flatness inspection using high-precision instruments

- Ultrasonic and visual examination to detect internal and surface defects

- Mechanical testing for tensile strength, hardness, and elongation

- All inspection data are documented, traceable, and comply with international quality standards.

R&D and Customization

Backed by a strong R&D team with over 30 years of experience, we offer tailored solutions for customers requiring specific dimensions, grades, or surface finishes. Our engineers continuously innovate in tantalum alloy development and forming technologies to enhance material performance. Whether for vacuum coating targets, chemical processing liners, or precision machined components, customized Tantalum Metal Plate products are available to meet diverse industrial needs.

Packaging & Global Logistics

Each Tantalum Metal Plate is packaged with care to ensure safety during international transport. Packaging includes vacuum sealing or anti-rust film wrapping, foam protection, and export-standard wooden crates. Clear labeling of product specifications, heat numbers, and batch details ensures full traceability. With reliable air, sea, and land shipping solutions, Shaanxi Chuanghui Daye ensures fast and damage-free global delivery to over 50 countries.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

OEM & Customization Service

We provide OEM and ODM services to support our global partners. Our customization capabilities include tailored plate dimensions, alloy compositions, and special surface treatments. Prototype production and small-batch manufacturing are also available for research and development projects. Technical consultation, design assistance, and full after-sales support ensure that every customer receives a precise Tantalum Metal Plate solution that fits their requirements.

Inspection Process

- Raw material chemical analysis

- Ingot melting verification

- Rolling and forging inspection

- Surface and dimensional measurement

- Mechanical and microstructural testing

- Final quality audit and packing inspection

Our professional inspection team ensures that every plate meets the exacting standards of purity, thickness, and mechanical properties before shipment.

Why Choose Us

- Over 30 years of expertise in rare metal manufacturing

- ISO 9001:2015 certified production and inspection system

- Complete in-house facilities for melting, forging, and machining

- Flexible OEM services and fast delivery within 7 days for standard items

- Trusted by clients in 50+ countries across aerospace, chemical, and medical industries

|

|

|

|

|

|

FAQs

Q1: What is the typical purity level of your Tantalum Metal Plate?

A1: We offer standard purity of 99.95% and ultra-high purity up to 99.99% upon request.

Q2: Can you provide custom dimensions and surface finishes?

A2: Yes, customized sizes, surface polishing, and machining are available according to drawings or technical requirements.

Q3: What standards do your products comply with?

A3: Our plates are produced in accordance with ASTM B708 and ISO 9001:2015 standards.

Q4: How do you ensure product quality?

A4: Each production stage undergoes strict inspection, and test reports are provided before shipment.

Q5: What are your typical lead times?

A5: Standard sizes can be delivered within 7 days; custom orders may vary depending on specifications.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email

_1760924447399.jpg)