- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Straight Titanium Wire

Length: 500-3000mm

Product Overview

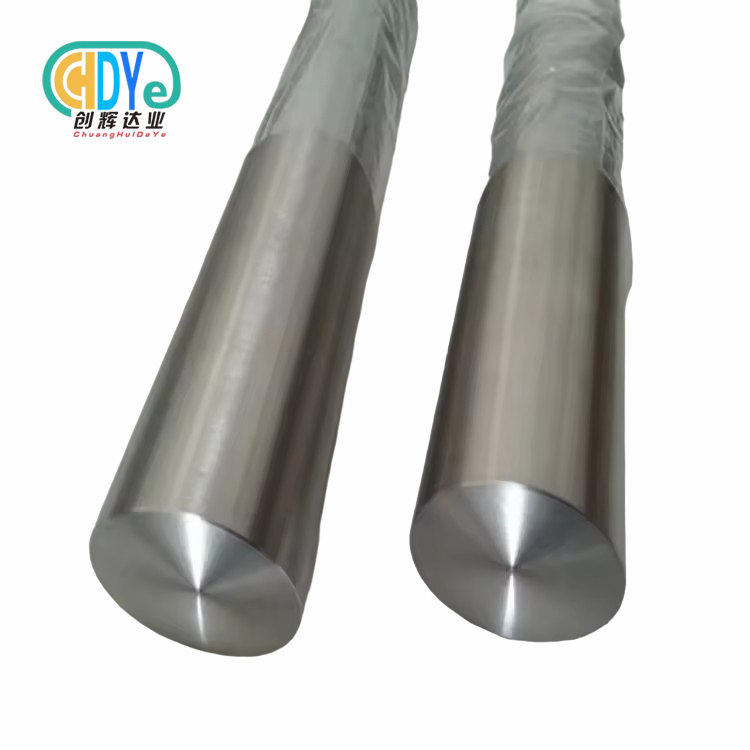

Straight Titanium Wire supplied by Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a precision-engineered titanium product designed for applications that demand exceptional dimensional accuracy, surface quality, and mechanical stability. Unlike coiled or spooled wire, our straight titanium wire is stress-relieved and cut to specific lengths, ensuring perfect linearity and ease of assembly in high-performance systems.

Manufactured in Baoji—China’s “Titanium Capital”—our straight titanium wire leverages advanced vacuum melting, multi-pass drawing, and straightening technologies. It provides superior tensile properties, corrosion resistance, and surface finish, making it ideal for industries such as aerospace, medical, electronics, and chemical engineering.

Straight Titanium wire is a high-performance metal material with the characteristics of high strength, light weight and corrosion resistance. These characteristics make it widely used in many fields, such as aerospace, medical equipment and chemical equipment.

Straight Titanium Wire Size Range: Min diameter: 0.5 mm -Max diameter: 7.0mm

Length: 500-3000mm

Technical Specifications

| Parameter | Specification |

|---|---|

| Material Grade | Gr1, Gr2, Gr3, Gr5 (Ti6Al4V) |

| Standard | ASTM B863 / ASTM F67 / AMS 4954 |

| Diameter Range | 0.8 mm – 8.0 mm |

| Length | 100 mm – 3000 mm (custom available) |

| Density | 4.51 g/cm³ |

| Tensile Strength | 350–895 MPa (depending on grade) |

| Elongation | ≥ 20% |

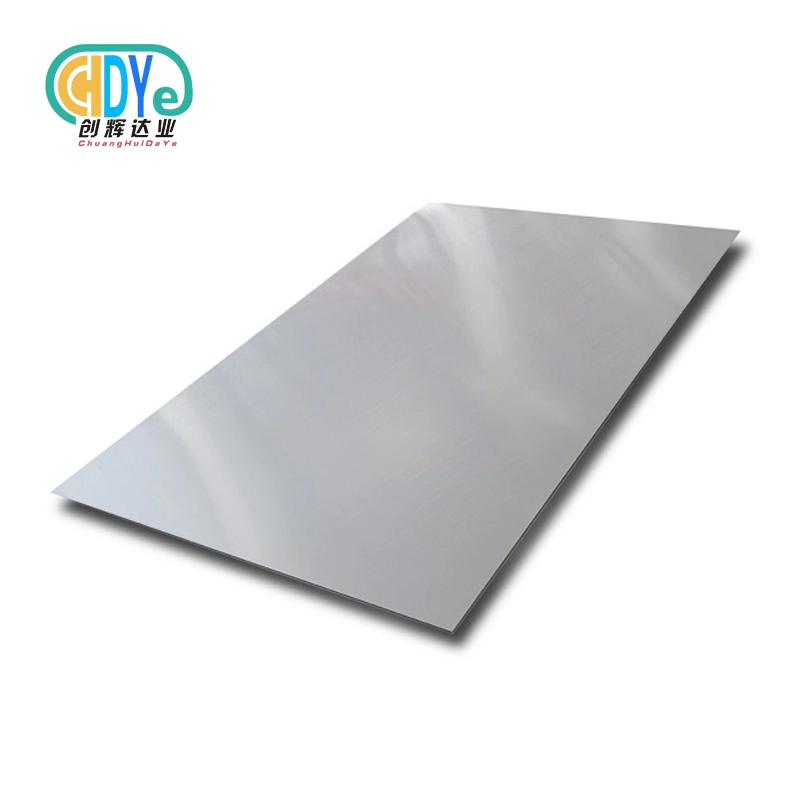

| Surface Finish | Polished, Bright, Ground, Pickled |

| Straightness Tolerance | ≤ 0.1 mm/m |

| Delivery Condition | Straight annealed or cold drawn |

| Certificates | ISO 9001:2015 / EN 10204 3.1 / SGS |

Features Of titanium wire

1. High strength: The mechanical strength of titanium straight wire is similar to that of steel, twice that of aluminum, and five times that of magnesium.

2. Light weight: The density of titanium is 4.54g/cm³, which is 43% lighter than steel and slightly heavier than magnesium.

3. Corrosion resistance: Titanium straight wire performs well in corrosive environments and has excellent corrosion resistance

4. High temperature resistance: The melting point of titanium is 1942K, which is nearly 1000K higher than gold and nearly 500K higher than steel

5. Biocompatibility: Titanium straight wire has good biocompatibility and is suitable for medical devices and implants

Mechanical & Surface Performance

- Exceptional Straightness: Advanced straightening process ensures linear deviation under 0.1 mm/m.

- High Dimensional Precision: Achieved through multi-step cold drawing and laser measurement.

- Uniform Microstructure: Vacuum melting and controlled annealing create stable metallographic properties.

- Corrosion Resistance: Performs reliably in strong acids, alkalis, and seawater conditions.

- High Temperature Tolerance: Retains mechanical integrity up to 600°C.

- Low Magnetic Permeability: Suitable for electronic and instrumentation use.

Unique Product Advantages

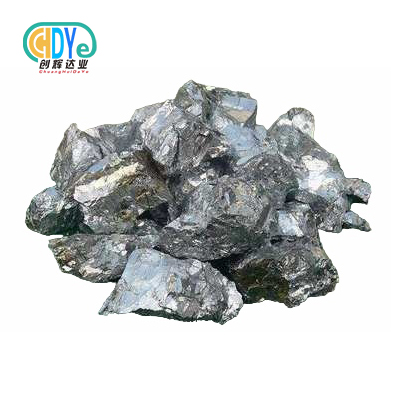

- Direct Manufacturing Source: Produced in-house with full control from titanium sponge to final straight wire.

- Stress-Relieved Finish: Prevents warping or bending during welding and machining.

- High Load-Bearing Strength: Excellent for high-tension and structural applications.

- Mirror Polishing Option: Enhances aesthetic and anti-contaminant properties for visible components.

- Custom Length Cutting: Each wire can be cut, chamfered, or threaded to exact client specifications.

- Consistent Quality Batch-to-Batch: Supported by real-time process monitoring and automated inspection.

- Non-Toxic and Biocompatible: Safe for contact in medical, dental, and food environments.

Manufacturing & Processing Flow

- Titanium Sponge Refinement – Certified raw materials sourced and analyzed before melting.

- Vacuum Melting (VAR/EBM) – Ensures homogeneous purity and eliminates gas inclusions.

- Forging & Rolling – Billets converted into rods with refined grain structure.

- Cold Drawing – Achieves precise diameters and enhances tensile strength.

- Annealing Treatment – Relieves internal stress for dimensional stability.

- Straightening & Cutting – High-speed straighteners achieve exact length and straightness tolerance.

- Surface Finishing – Polishing or pickling to obtain bright, smooth surfaces.

- Inspection & Packaging – 100% dimensional, visual, and mechanical testing before shipment.

|

|

|

|

|

|

|

|

Quality Control & Inspection

Each piece of Straight Titanium Wire undergoes rigorous multi-stage inspection, including:

- Chemical Composition Test (ICP-OES Analysis)

- Tensile & Yield Strength Test

- Ultrasonic & Eddy Current Testing for internal defects

- Straightness and Diameter Verification

- Surface Defect Detection using digital microscopy

- Mechanical Consistency Check across batch production

Our factory is certified under ISO 9001:2015, with full traceability supported by Material Test Certificates (MTC) and EN 10204 3.1 documentation.

Application Advantages

Aerospace:

Used in aircraft structural fasteners, engine assemblies, and connecting elements where weight and corrosion resistance are critical.

Medical Industry:

Applied in orthopedic implants, surgical instruments, guide wires, and dental supports requiring biocompatibility.

Electronics & Semiconductors:

Ideal for precision contacts, lead wires, and high-temperature electrical components.

Chemical Equipment:

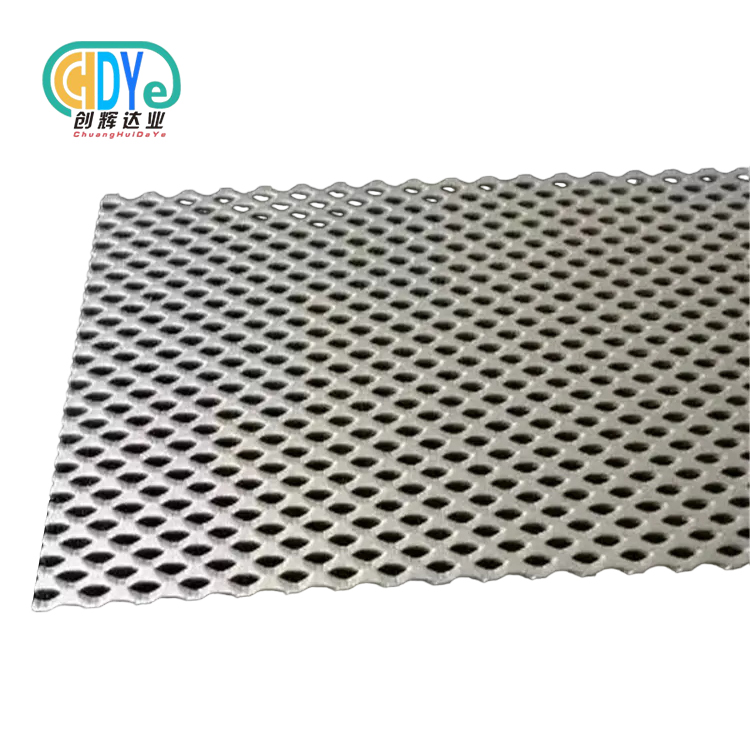

Used in electrode frames, filter supports, and corrosion-resistant hardware in reactors and heat exchangers.

Marine & Offshore:

Perfect for underwater structural components, fasteners, and submersible connectors.

Industrial Manufacturing:

Applied in 3D printing feedstock, industrial brushes, and mechanical reinforcement systems.

Be used in a wide range of industries.

Marine engineering

Medical implants

Medical Equipment

Chemical Processing

Aerospace and Defense

Energy and Environmental Engineering

R&D and Customization

- Custom diameter, tolerance, and mechanical property adjustment

- Precision cutting from 100 mm to 3000 mm

- Polished, matte, or pickled surface finish options

- OEM branding and labeling service for distributors

- Trial batch production for prototype evaluation

- R&D collaboration for new material and alloy compositions

We support customers in developing innovative titanium wire solutions for advanced industries through material optimization and custom processing.

Packaging & Global Logistics

To ensure safety and quality during long-distance transport, all wires are packaged with care:

- Inner Layer: PE anti-corrosion wrapping

- Intermediate Layer: Foam protection or bubble film

- Outer Layer: Strong export-standard wooden case or carton

- Labeling: Product grade, diameter, lot number, and net weight

- Shipping Options: Express (DHL, FedEx), Air cargo, or Sea freight

Our logistics partners provide door-to-door delivery and customs documentation for over 60 countries.

|

|

|

|

|

|

|

|

|

|

|

|

Feedback from customers

Global Partnership & Case References

Shaanxi Chuanghui Daye has supplied straight titanium wire to aerospace, medical, and high-end industrial clients worldwide.

- USA & Germany: High-precision titanium wires for surgical and instrumentation systems.

- Japan & South Korea: Aerospace component producers for structural fastening.

- Europe & Middle East: Chemical and offshore energy applications with strict corrosion resistance requirements.

Our partners value consistent performance, traceable quality, and technical support that help them improve reliability and competitiveness.

Why Choose Us

- Over 30 years of titanium wire manufacturing expertise

- In-house melting to machining full production chain

- Advanced straightening and polishing lines for perfect dimensional control

- ISO, ASTM, and AMS standard compliance

- OEM/ODM customization and engineering support

- Professional after-sales technical consultation

- 7–10 days fast delivery for standard specifications

Choosing Chuanghui Daye means partnering with a supplier dedicated to precision, purity, and performance.

|

|

|

|

|

|

FAQ

Q1: What’s the maximum length you can provide for straight titanium wire?

We can supply up to 3 meters in single-piece length or as per customer drawing.

Q2: Can I order specific cut lengths for assembly use?

Yes, we provide precision cutting and chamfering to meet exact dimensional needs.

Q3: What surface finishes are available?

Polished, pickled, bright, and mirror surface options are available for different industries.

Q4: What is your MOQ for customized wire?

Usually 5 kg for standard sizes, smaller trial quantities for prototypes are accepted.

Q5: Can you provide mechanical property adjustments?

Yes, annealing or cold drawing can be tailored to achieve specific strength and hardness requirements.

Contact Us

Shaanxi Chuanghui Daye Metal Material Co., Ltd.

Address: Room 303, Block A, Lansi Science Park, 128 Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi Province, China.

Email: info@chdymetal.com

WhatsApp: +8618049386902

Business Hours: Monday – Saturday, 8:30 AM – 6:00 PM

Learn about our latest products and discounts through SMS or email